Digital large-power high-frequency inversion controller for direct-current power supply and method of controller

A technology of high-frequency inverter and DC power supply, which is applied in the direction of converting DC power input to DC power output, control/regulation system, and output power conversion device, etc. It can solve the problem of large output voltage ripple, poor stability, and low efficiency. problem, to achieve the effect of simple power output control and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

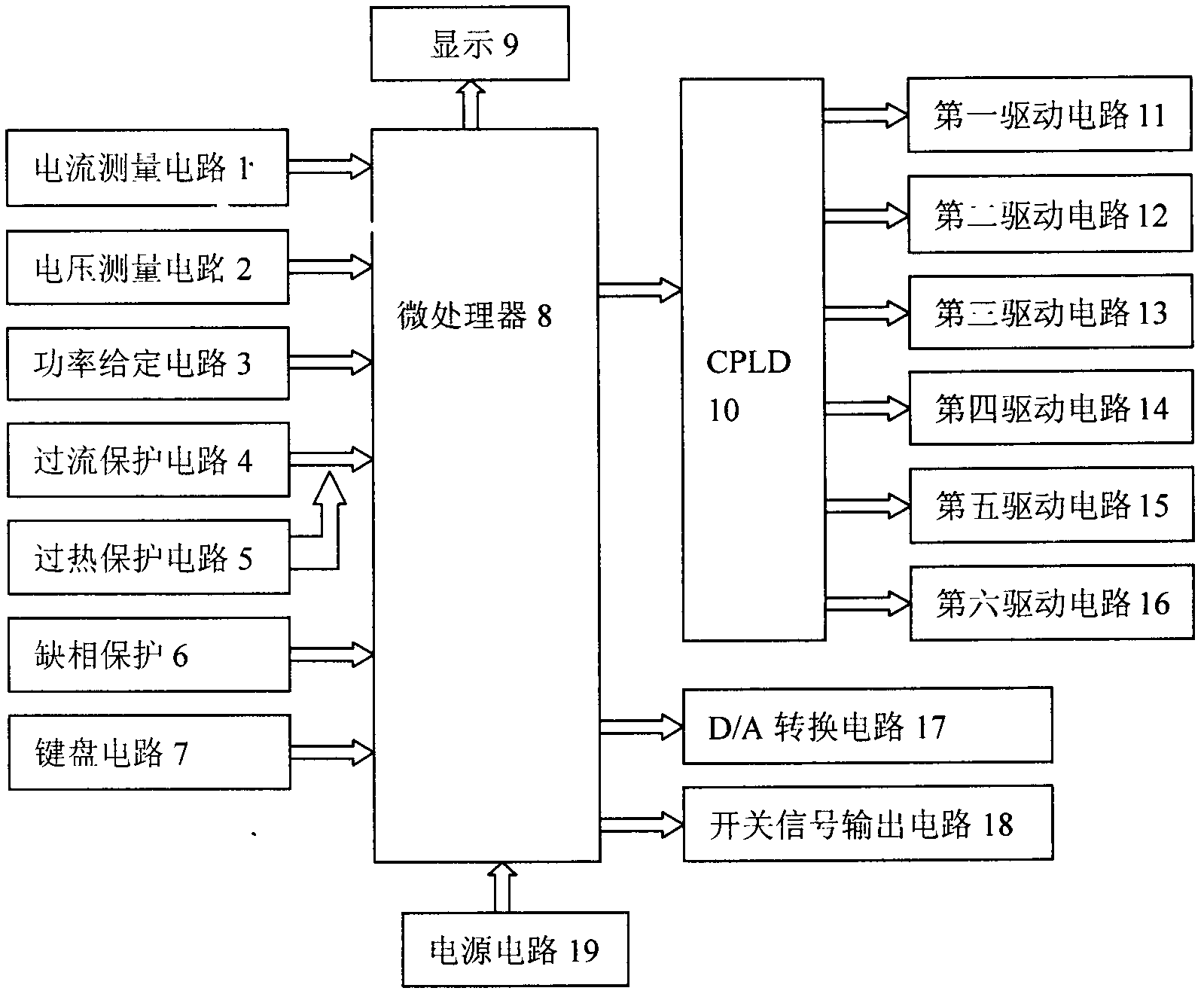

[0017] See figure 1 As shown, the digital high-power high-frequency inverter DC power supply controller and its method in this embodiment include a current measurement circuit 1, a voltage measurement circuit 2, a power setting circuit 3, an overcurrent protection circuit 4, and an overheating protection circuit. 5. Phase loss protection 6, keyboard circuit 7, microprocessor 8, display 9, CPLD10, first drive circuit 11, second drive circuit 12, third drive circuit 13, fourth drive circuit 14, fifth drive circuit 15 , the sixth drive circuit 16, D / A conversion circuit 17, switch signal output circuit 18 and power supply circuit 19; / D port is connected; the output end of overcurrent protection circuit 4, overheating protection circuit 5 and phase loss protection 6 is connected with the I / O mouth of microprocessor 8 respectively; The output end of keyboard circuit 7 is connected with the I / O port of microprocessor 8 O mouth is connected; Display 9 input ends are connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com