Steel ingot rolling automatic control system and control method thereof

An automatic control system and steel ingot technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of unrecognizable systems, achieve simple and effective operation, fill technical gaps, and expand thickness and width group spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

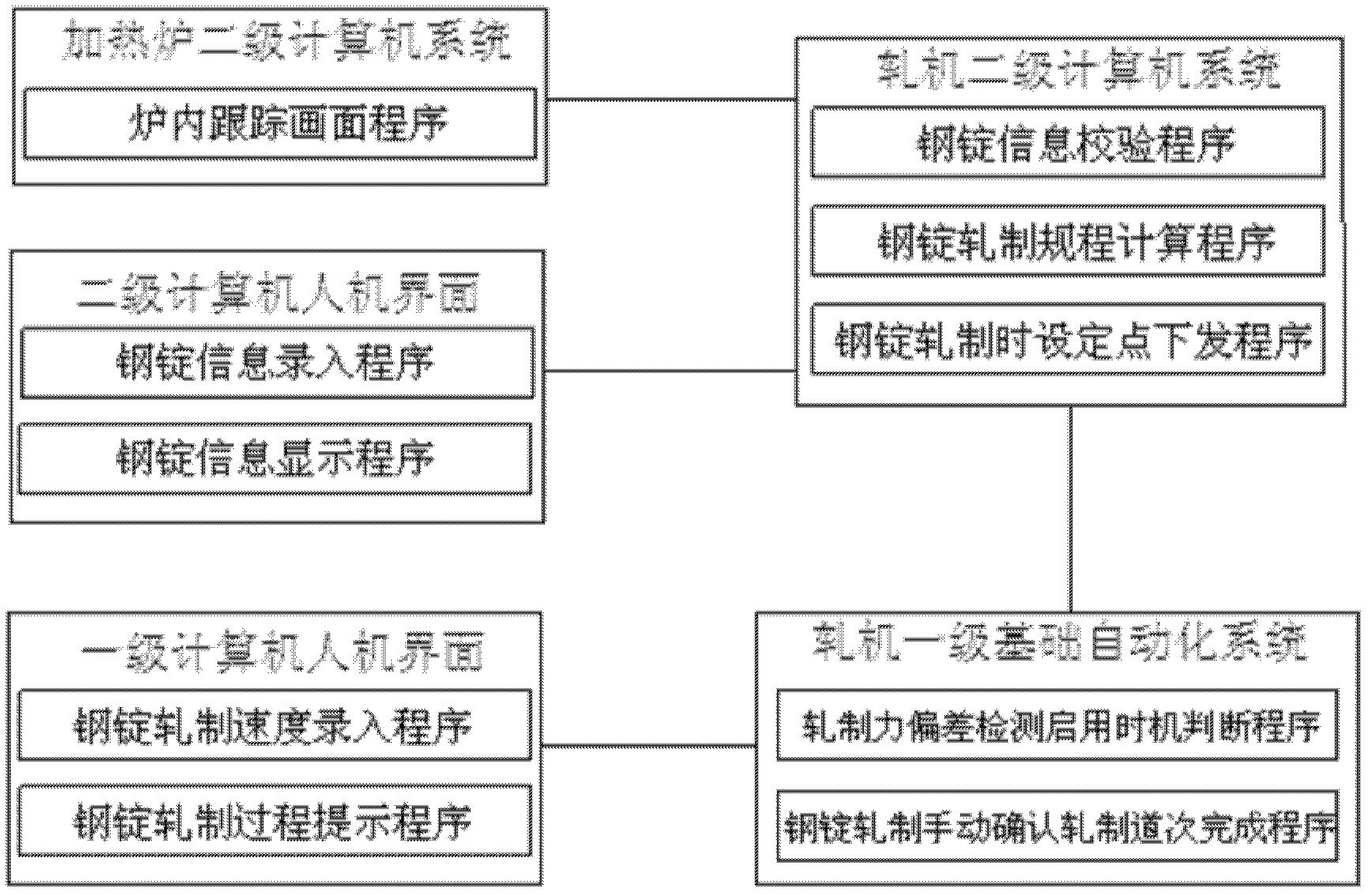

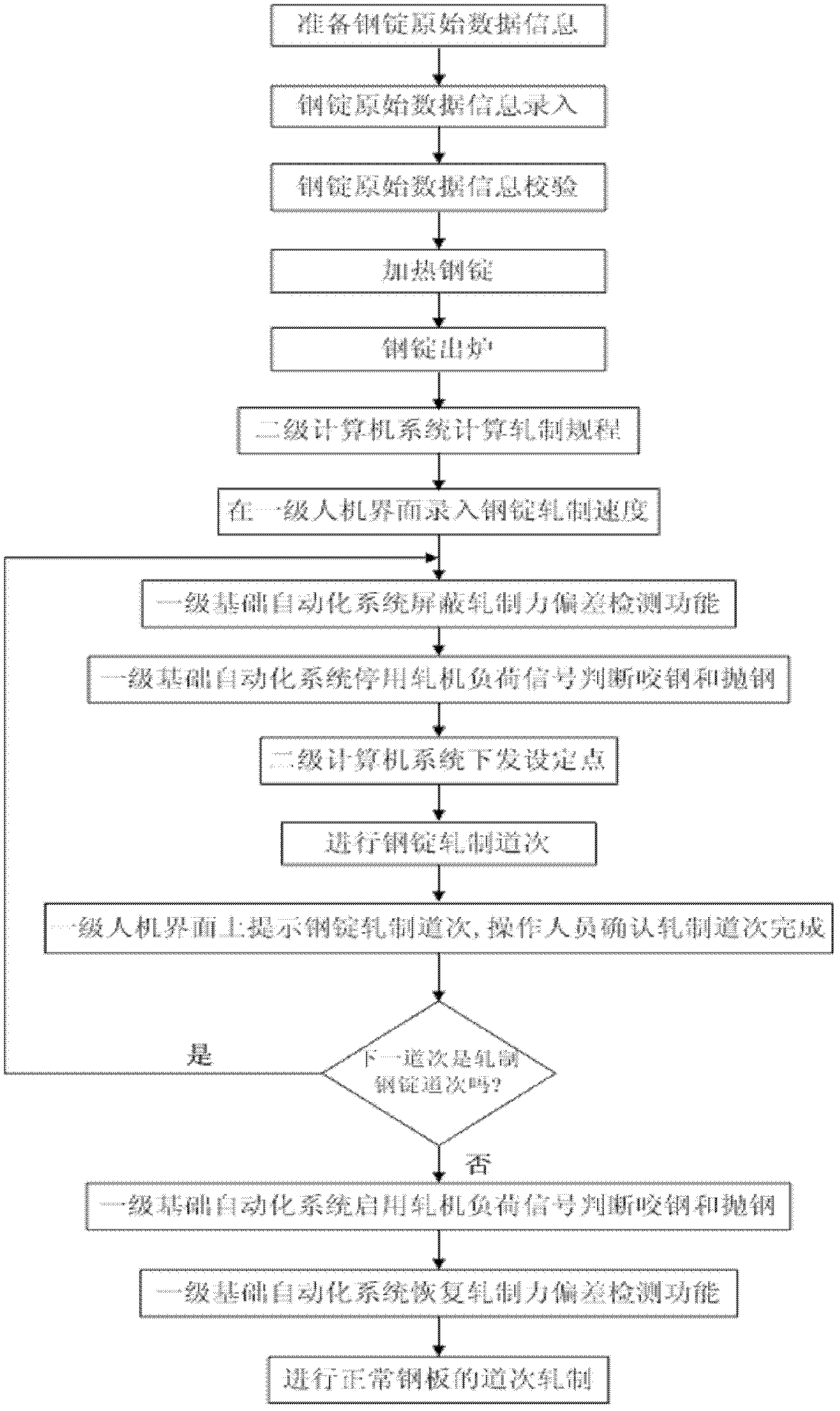

[0028] As can be seen from the block diagram of the steel ingot rolling automatic control system, the steel ingot rolling automatic control system of the present invention mainly utilizes the original secondary computer system of the heating furnace, the secondary computer system of the rolling mill, the primary automation system of the rolling mill and includes: It is realized by the man-machine interface system of the secondary computer. The concrete solution that the present invention takes is:

[0029] In the tracking screen of the secondary computer system of the heating furnace, a tracking screen program in the ingot furnace is added;

[0030] In the control program of the secondary computer system of the rolling mill, a steel ingot information verification program, a steel ingot rolling schedule calculation program and a steel ingot rolling set point issuing program are added;

[0031] In the control program of the first-level basic automation system of the rolling mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com