Method for increasing diantimony trioxide particle size during wet production process of diantimony trioxide

A technology of antimony trioxide and wet method, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

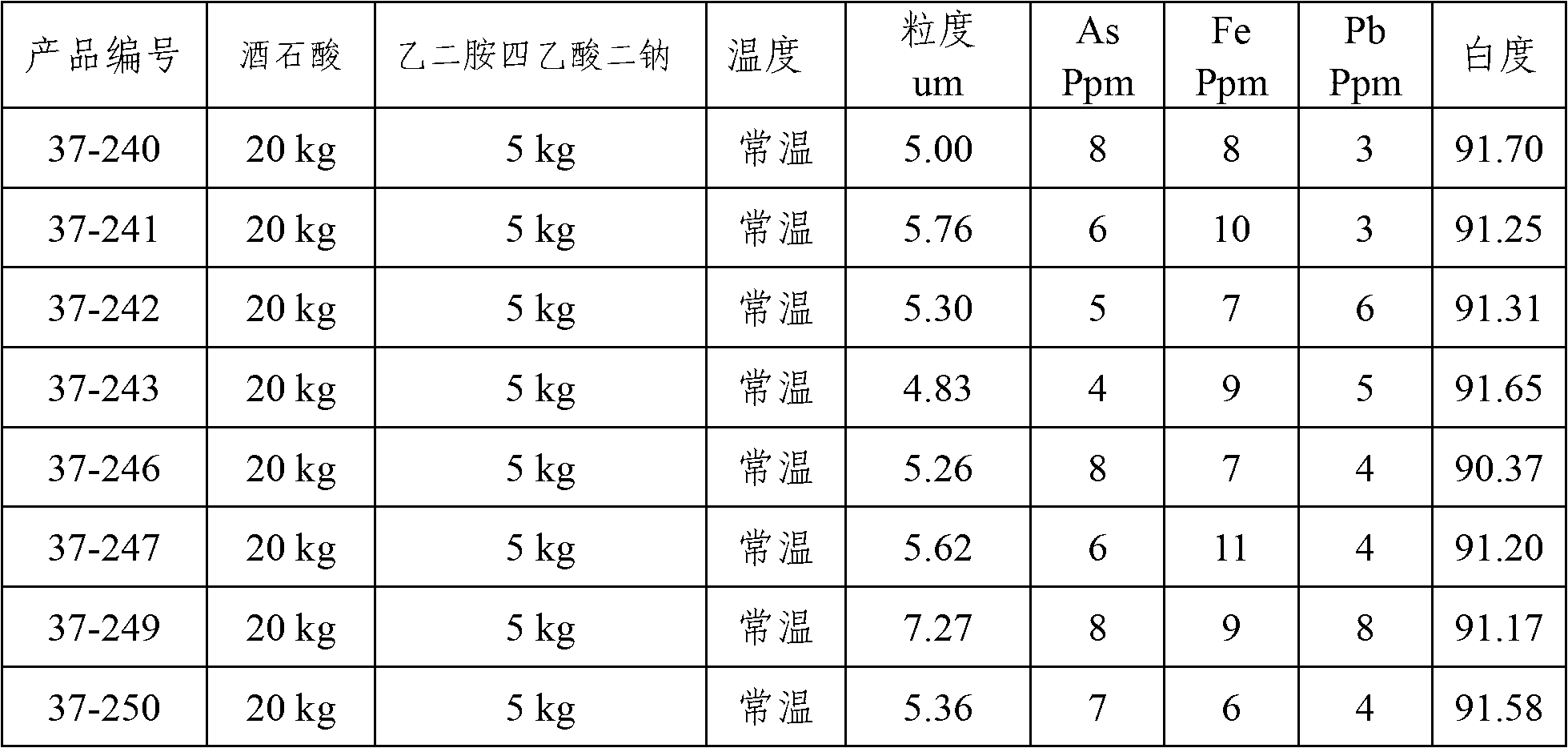

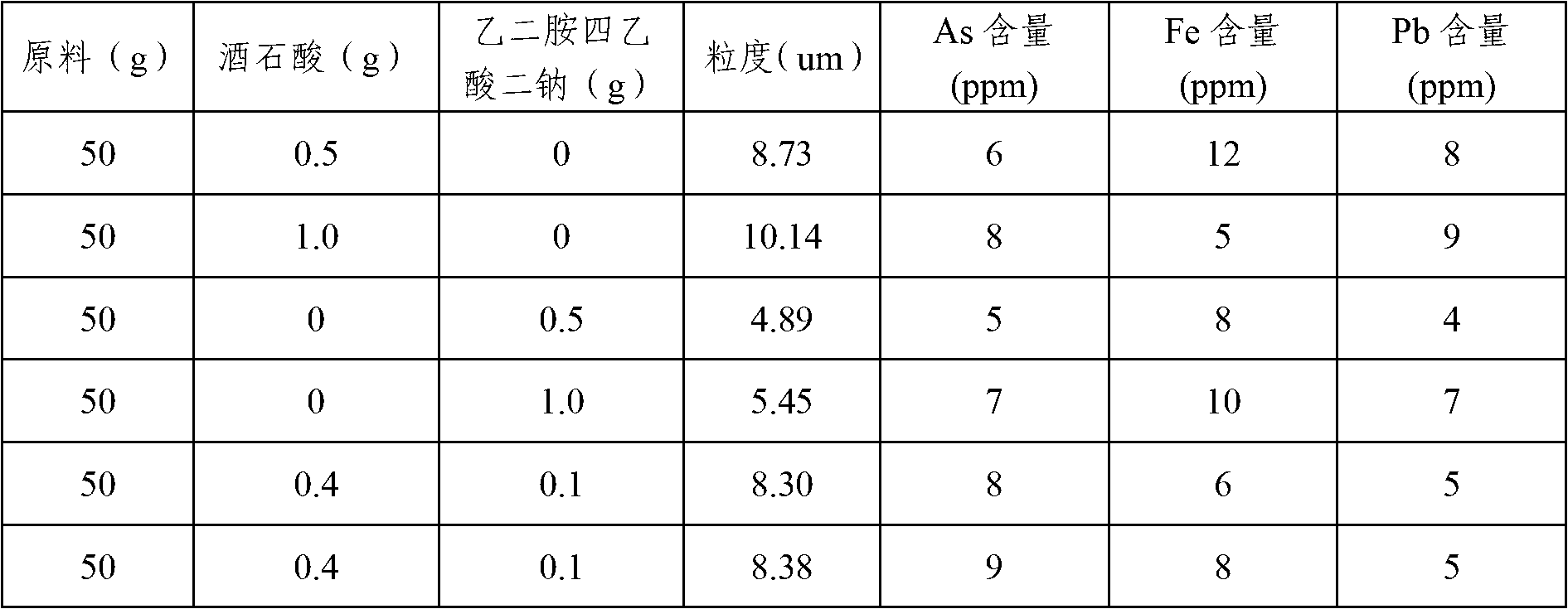

Examples

Embodiment Construction

[0035] The following examples are intended to further illustrate the present invention, rather than limit the present invention.

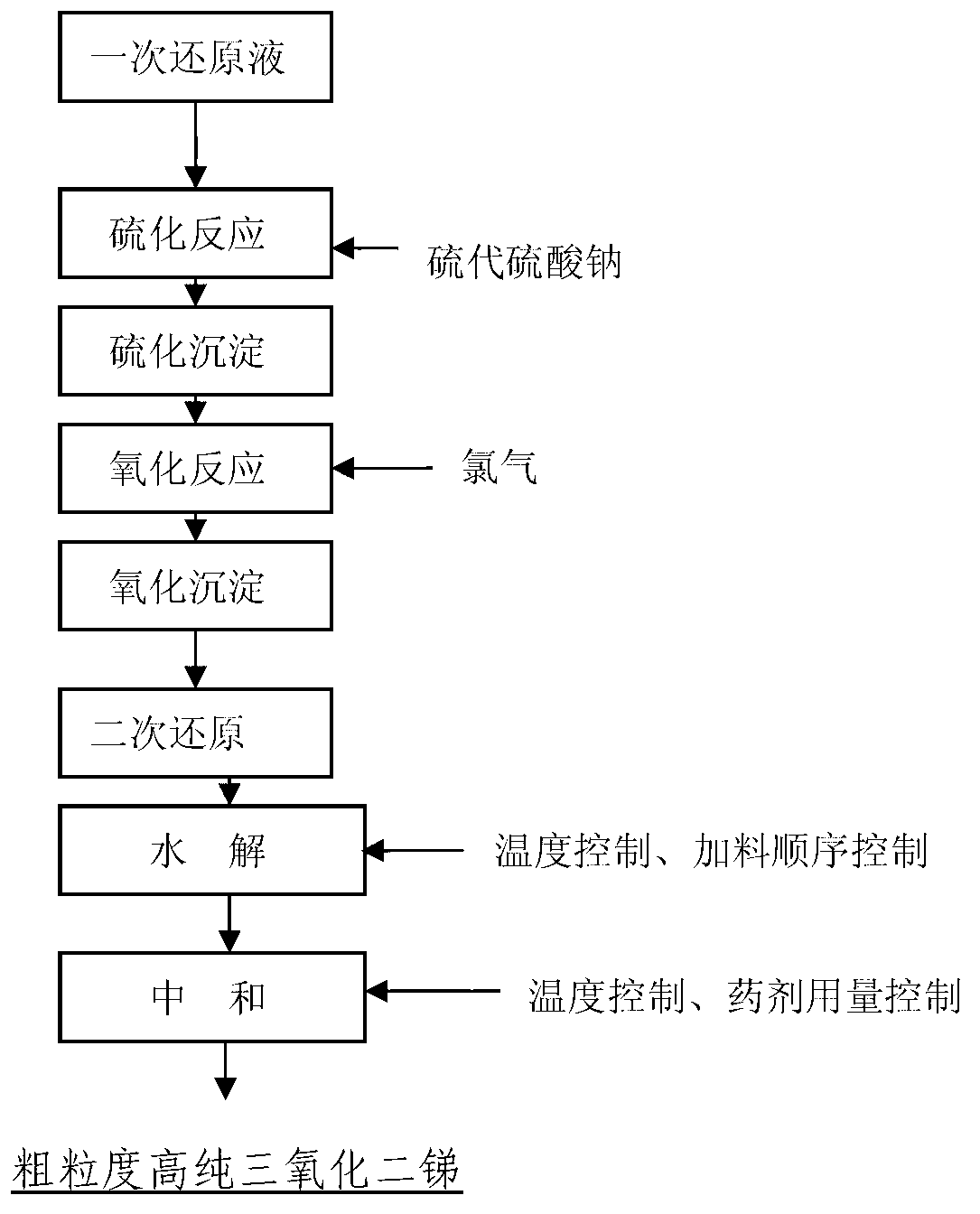

[0036] The flow process of industrialized production of the present invention is as follows:

[0037] Table 1 Contents of main components of a certain mineral source

[0038] Sb% Pb% As% Bi% Cu% Aug / t SiO 2 % h 2 O% 45.38 0.59 0.27 0.0018 0.1 0.5 26.58 14.4

[0039] Add the chlorinated leaching solution of the -80 mesh antimony sulfide concentrate to the antimony sulfide concentrate for primary reduction; add sodium thiosulfate to the primary reduction solution to remove impurities, and the added quality of sodium thiosulfate is 0.8% of the mass content of arsenic in the primary reduction solution. ~1.4 times; (sodium thiosulfate is industrial grade, main content 99.96%) react for 2-5 hours. Filter, and the filtrate precipitates for no less than 2 hours. Filter the precipitated solution, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com