Method for tanning ecological automobile leather in unsalted no-pickling manner

A technology for automotive leather and tanning, which is applied in leather drying, chemical treatment before tanning, leather surface treatment, etc. It can solve problems affecting product stability, trivalent chromium pollution, hexavalent chromium pollution, etc., and achieve good production stability, The process is simple and easy, and the effect of eliminating environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the examples, but it is not intended to limit the protection scope of the invention.

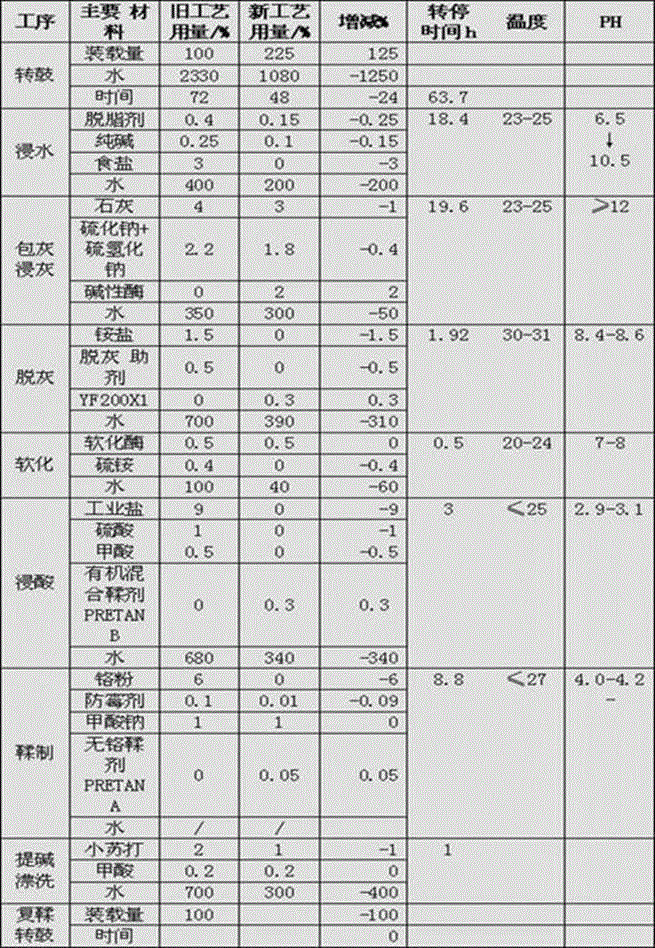

[0035] A method for tanning ecological automobile leather without salt and without pickling, comprising the following techniques:

[0036] A pre-tanning process:

[0037] The pre-tanning process mainly includes: soaking in water, dehairing, liming, deliming and softening, tanning without salt and pickling, etc. The main functions are summarized in two points: one is to remove the inside and outside of the skin that are useless for tanning; the other is to loosen collagen fibers, which is conducive to the entry of tanning agents, fatliquoring agents and other auxiliary agents. About 70% of the pollution comes from this section.

[0038] ① Raw leather batching: Mainly use raw hides with large width, sufficient thickness, tightly woven fibers, flat and fine grain, less disability, wide application, moder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com