Smelting technique for removing Sb under arc furnace conditions

A technology for electric arc furnaces and conditions, applied in electric furnaces, improvement of process efficiency, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

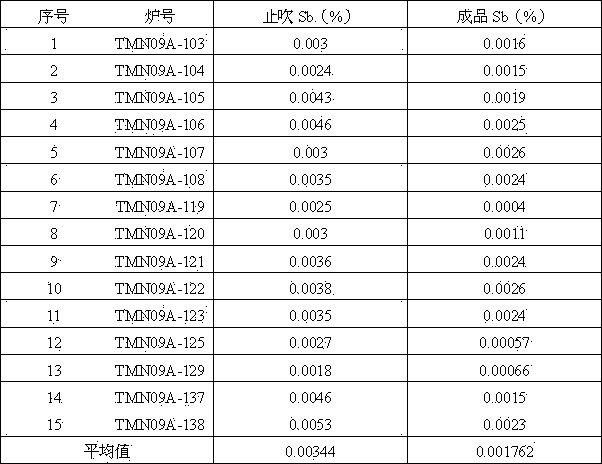

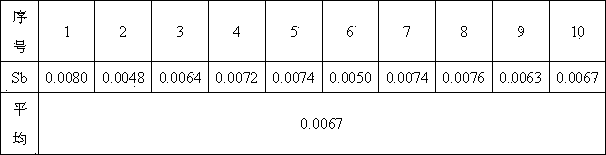

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment further illustrate the present invention.

[0024] A smelting process for removing Sb under electric arc furnace conditions is characterized in that it comprises the following steps:

[0025] (1) Charging: Lime and fluorite used as slag material in the bottom of the electric arc furnace, the weight ratio is lime: fluorite = 4:1, the total weight of lime and fluorite accounts for 4%-5% of the total molten steel;

[0026] (2) Melting period: Strictly control the operation and power supply system during the melting period to prevent local overheating of molten steel. The melting temperature is not higher than 1550°C;

[0027] (3) Oxidation period: decarburization rate ≤0.03% / min; oxidation period temperature 1550°C~1680°C, to ensure continuous temperature rise. When the temperature is around 1560°C and 1640°C, the oxygen blowing slag flow should be carried out once respectively, the outlet pressure of the oxygen blowing pipe is 0.2~0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com