Industrialized assembled multi-story high-rise steel structure prestressed centrally-braced system

A technology of central support system and industrialized assembly, which is applied in building construction, construction, etc., can solve the problems of unrealized high-rise lateral force resistance structure of prestressed steel members.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The implementation of the structural system will be described in detail below in conjunction with the accompanying drawings.

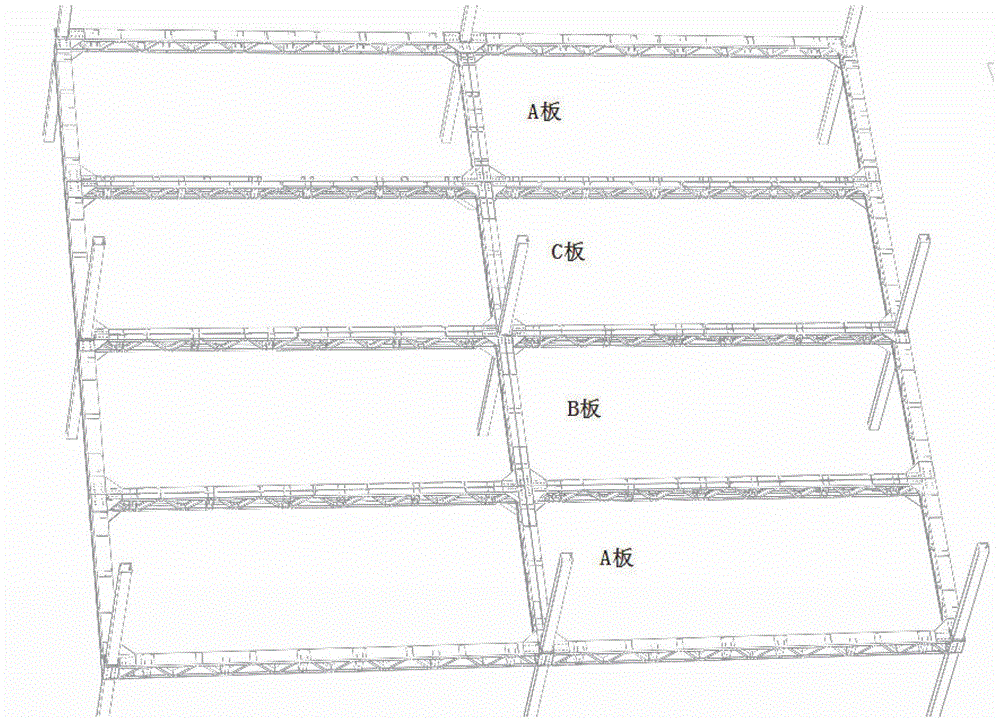

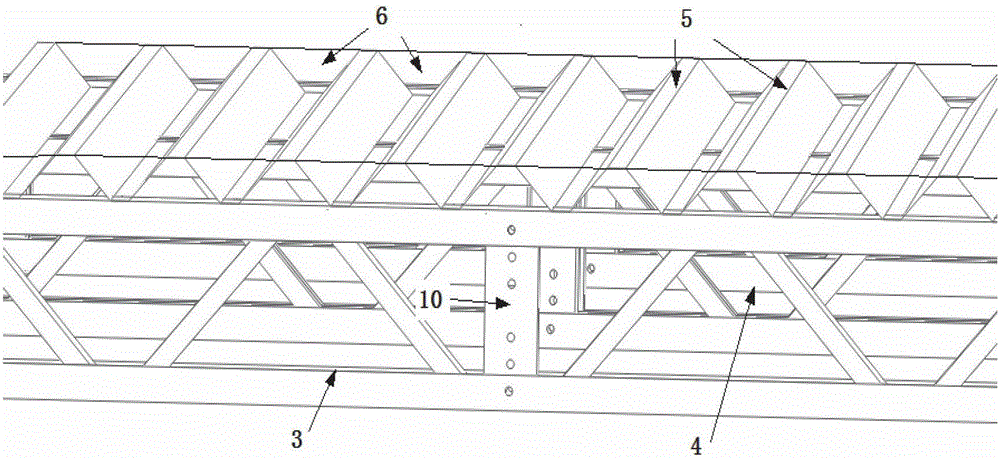

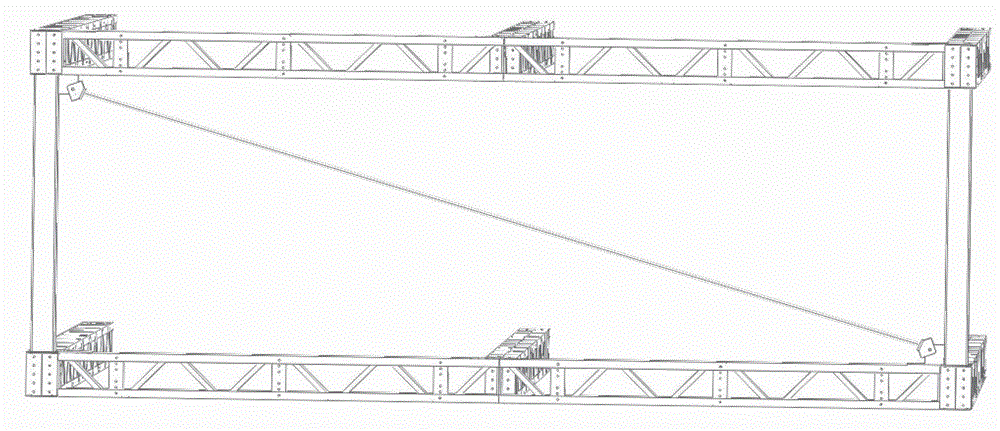

[0058] Such as Figure 1~10 As shown, the present invention is an industrially assembled multi-high-rise steel structure prestressed central support system, including a steel structure main frame, a prestressed support member, and a column system, and is characterized in that: the steel structure main frame includes a foundation Frame, column system. Wide beam 3, narrow beam 4 and column base 7 are assembled into foundation plate frame in factory, and floor slab is example with pressed steel plate concrete here, and floor slab can also be forms such as reinforced concrete floor slab. The prestressed support members are described here in a general form. Place the profiled steel plate 5 on the wide beam 3 and the narrow beam 4, connect it with studs, pour concrete 6 on the profiled steel plate 5, use the gaps between the webs of the wide beam 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com