High-temperature impact-pressure-resistant sensor and production method thereof

A pressure sensor, shock-resistant technology, applied in the field of sensors, can solve the problem of the sensor not working, achieve the effect of reliable performance and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

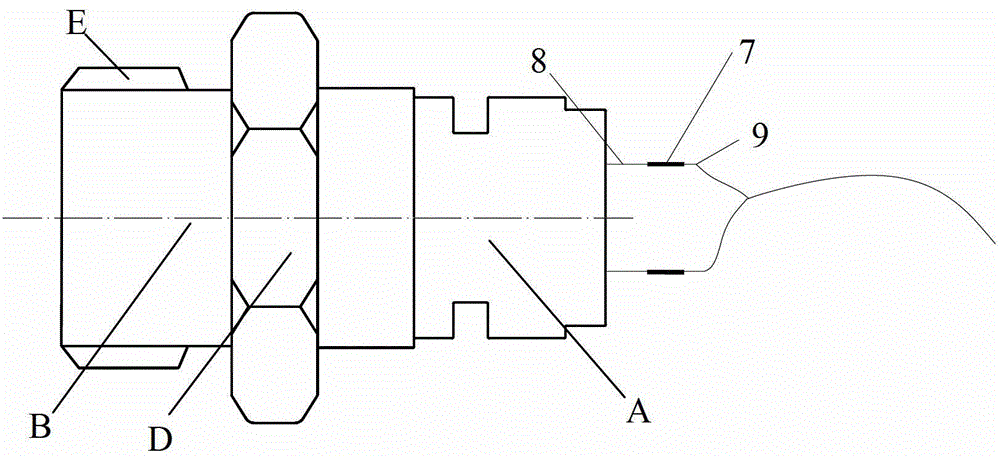

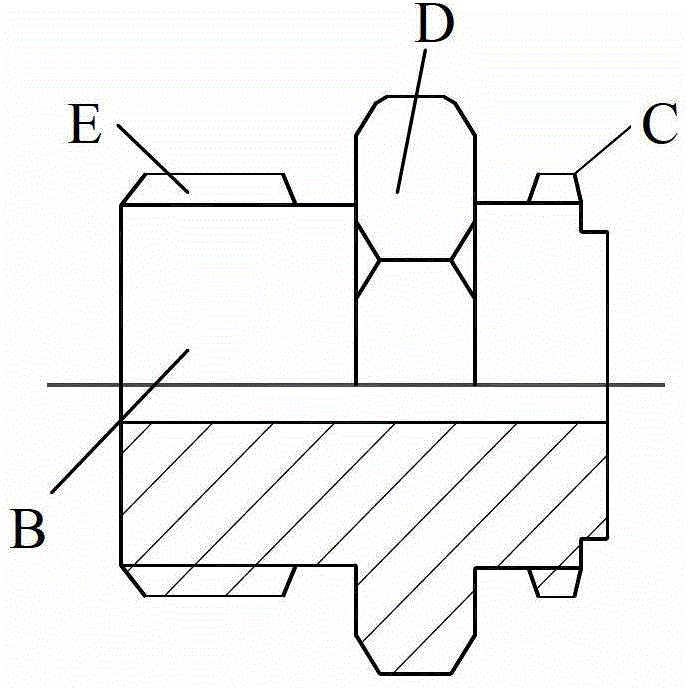

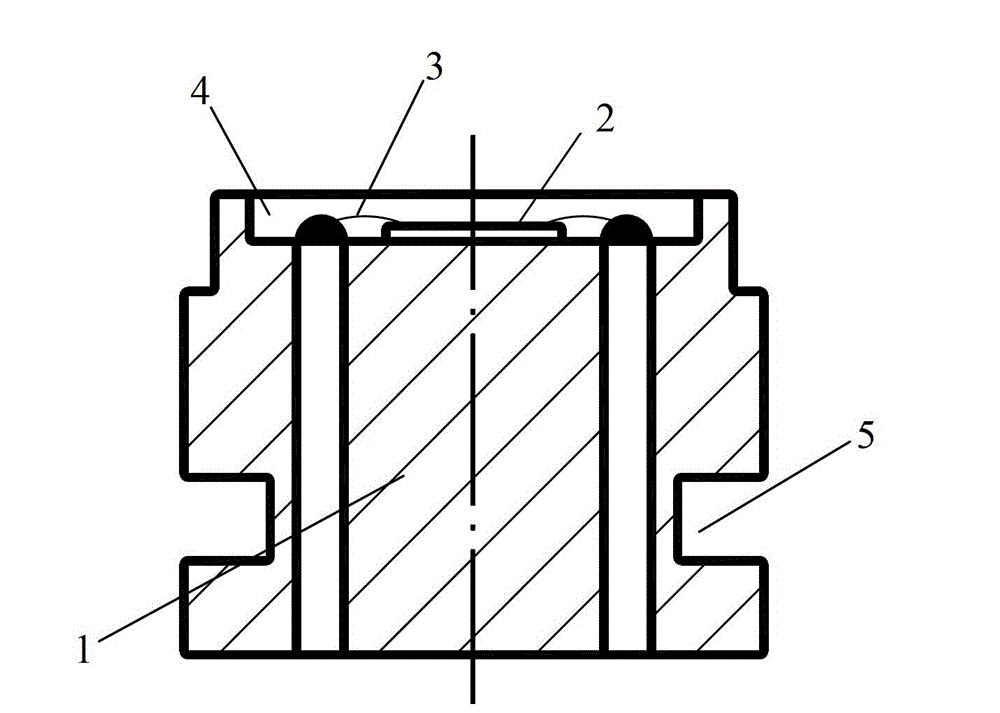

[0034] see Figure 1-3 , the high-temperature impact-resistant pressure sensor of the present invention includes a metal casing B and a core A enclosed in the metal casing B, the connecting part of the core A and the metal casing B is provided with threads, and the core A and the metal casing B are connected together by threads and laser welding; core A includes a cylindrical shell 1, and a horizontal groove 4 is arranged on the upper end of the shell 1, and an SOI chip 2 is arranged in the horizontal groove 4; the shell 1 Lead electrodes are arranged inside, and the pad electrodes of the SOI chip 2 are connected to the lead electrodes of the housing 1 through gold wires 3; the lead electrodes of the housing 1 are drawn out as inner leads 8, which are connected to the outer leads through the clamp 7 9. The lower part of the housing 1 is provided with an annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com