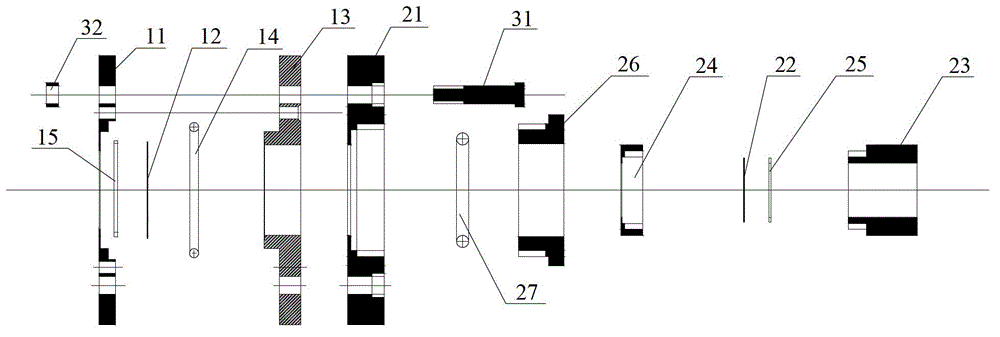

Synchrotron-radiation X-ray diffraction apparatus for analyzing electrochemical property of electrode material and application thereof

An electrode material and electrochemical technology, applied in the direction of material analysis using radiation, material analysis using radiation diffraction, etc., can solve the problems of non-reusable, poor signal accuracy of samples, etc., achieve great application value, and overcome the single test method , to achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

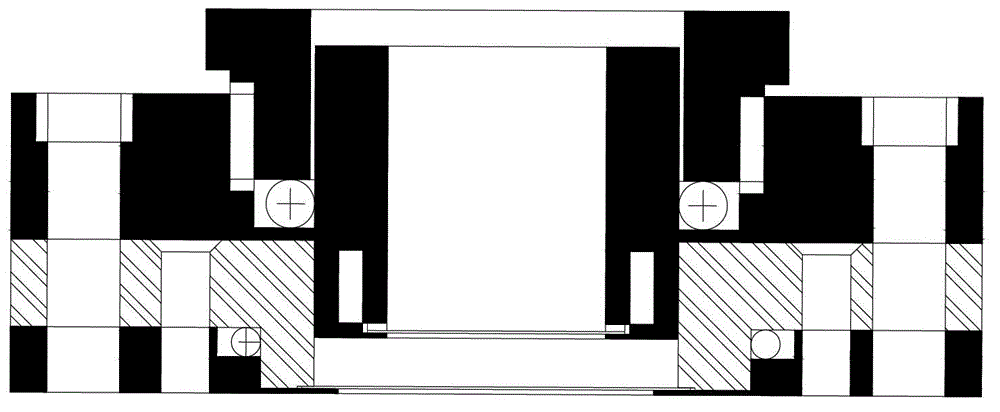

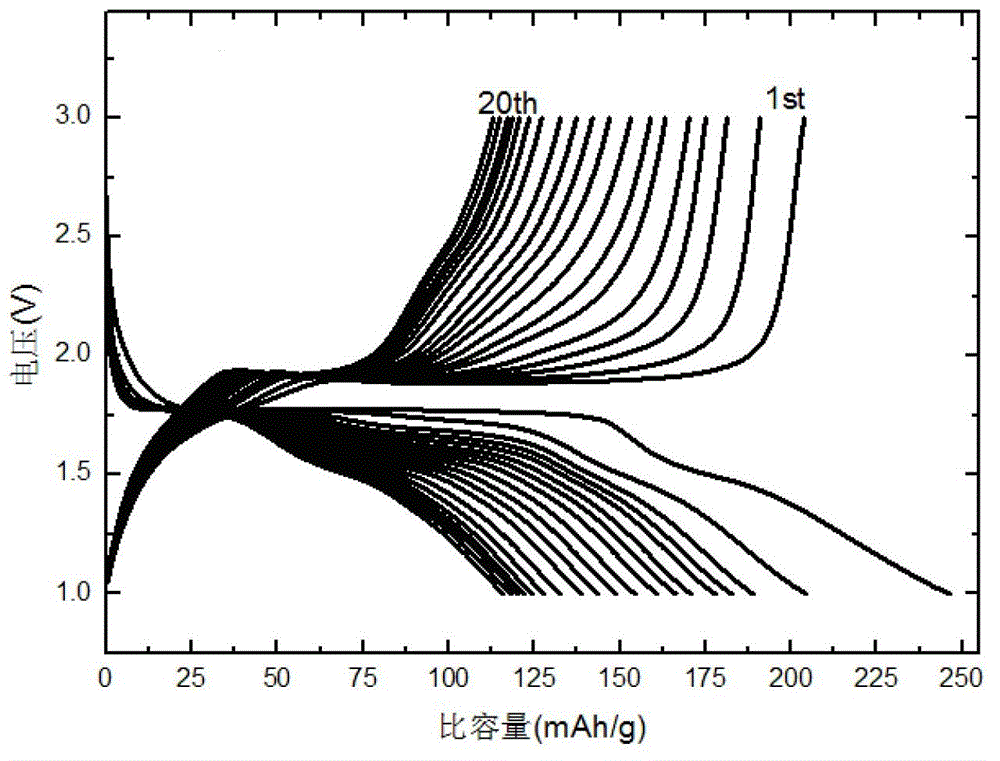

Embodiment 1

[0036] Anatase TiO 2 As the active material of the working electrode, it is ground and mixed with the conductive agent acetylene black (AB) and the binder vinylidene fluoride PVDF (with NMP as the solvent), and then the slurry is evenly coated on the aluminum foil and placed in the Dry in a vacuum oven at 80°C for more than 12 hours, and finally use a blunderbuss to form an electrode with a diameter of 10mm. The active material mass of each electrode is about 1.5mg; when the battery is assembled, the working electrode is placed in the component A part of the device of the present invention, Put the separator (Celegard2400) and the counter electrode lithium sheet in turn, and then drop a small amount of electrolyte (lithium hexafluorophosphate LiPF 6 Soluble in an organic solvent of ethylene carbonate EC and dimethyl carbonate DMC at a volume ratio of 1:1). Then press the spring on the lithium sheet, one can prevent the sliding of the electrode material, and the other can enha...

Embodiment 2

[0041] Anatase TiO 2 As the active material of the working electrode, it is ground and mixed with the conductive agent acetylene black (AB) and the binder vinylidene fluoride PVDF (with NMP as the solvent), and then the slurry is evenly coated on the aluminum foil and placed in the Dry in a vacuum oven at 80°C for more than 12 hours, and finally use a blunderbuss to form an electrode with a diameter of 10mm. The active material mass of each electrode is about 1.5mg; when the battery is assembled, the working electrode is placed in the component A part of the device of the present invention, Put the separator (Celegard 2400) and the counter electrode lithium sheet in turn, and then drop a small amount of electrolyte (lithium hexafluorophosphate LiPF 6 Soluble in an organic solvent of ethylene carbonate EC and dimethyl carbonate DMC at a volume ratio of 1:1). Then press the spring on the lithium sheet, one can prevent the sliding of the electrode material, and the other can enh...

Embodiment 3

[0045] Anatase TiO 2 As the active material of the working electrode, it is ground and mixed with the conductive agent acetylene black (AB) and the binder vinylidene fluoride PVDF (with NMP as the solvent), and then the slurry is evenly coated on the aluminum foil and placed in the Dry in a vacuum oven at 80°C for more than 12 hours, and finally use a blunderbuss to form an electrode with a diameter of 10mm. The active material mass of each electrode is about 1.5mg; when the battery is assembled, the working electrode is placed in the component A part of the device of the present invention, Put the separator (Celegard 2400) and the counter electrode lithium sheet in turn, and then drop a small amount of electrolyte (lithium hexafluorophosphate LiPF 6 Soluble in an organic solvent of ethylene carbonate EC and dimethyl carbonate DMC at a volume ratio of 1:1). Then press the spring on the lithium sheet, one can prevent the sliding of the electrode material, and the other can enh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com