Heat purge and trap instrument and heat purge and trap method

A thermal purging and trapping tube technology, applied in the field of purging and trapping, can solve the problems of long time, impurity component interference measurement, unfavorable environmental protection and health of operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

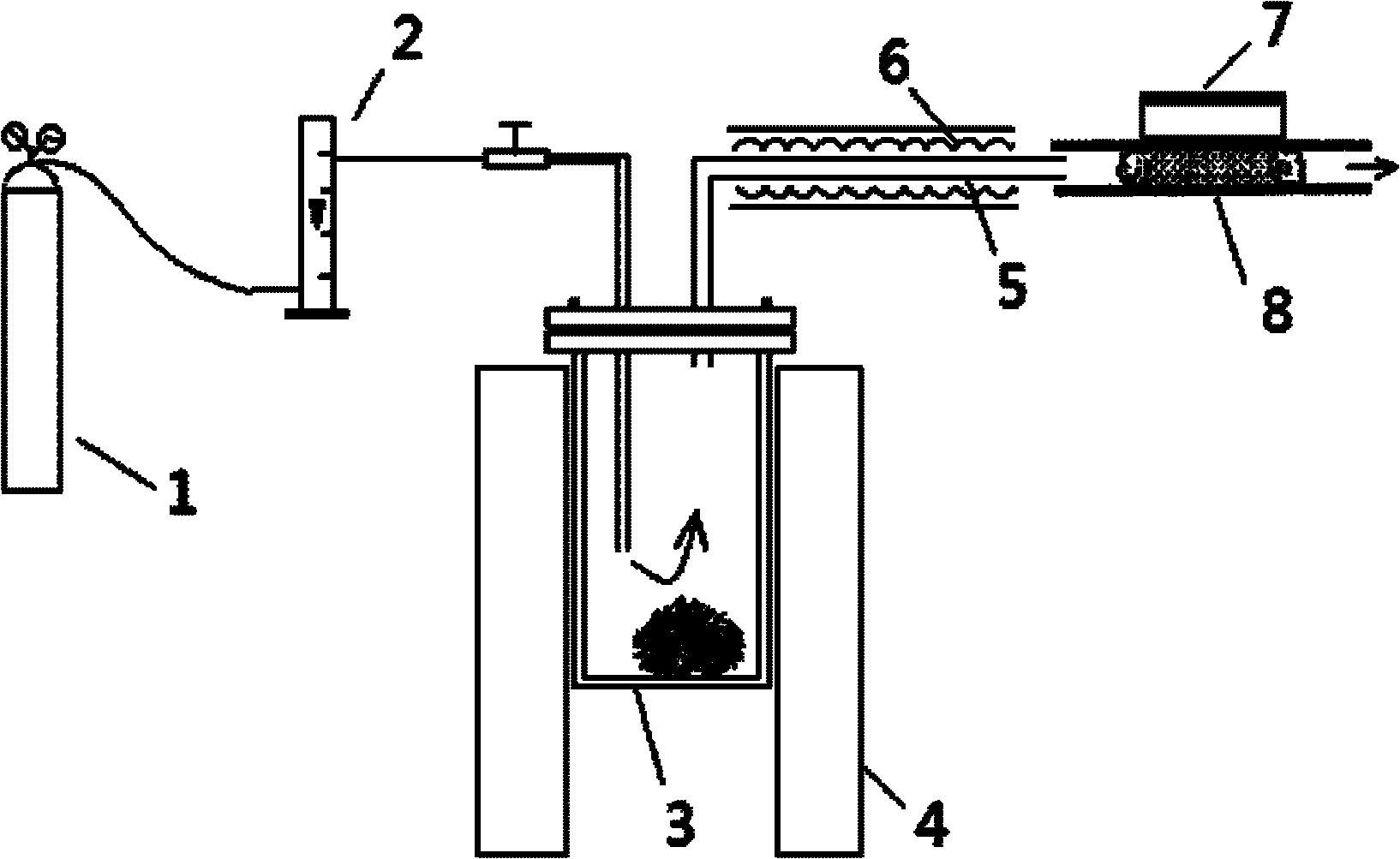

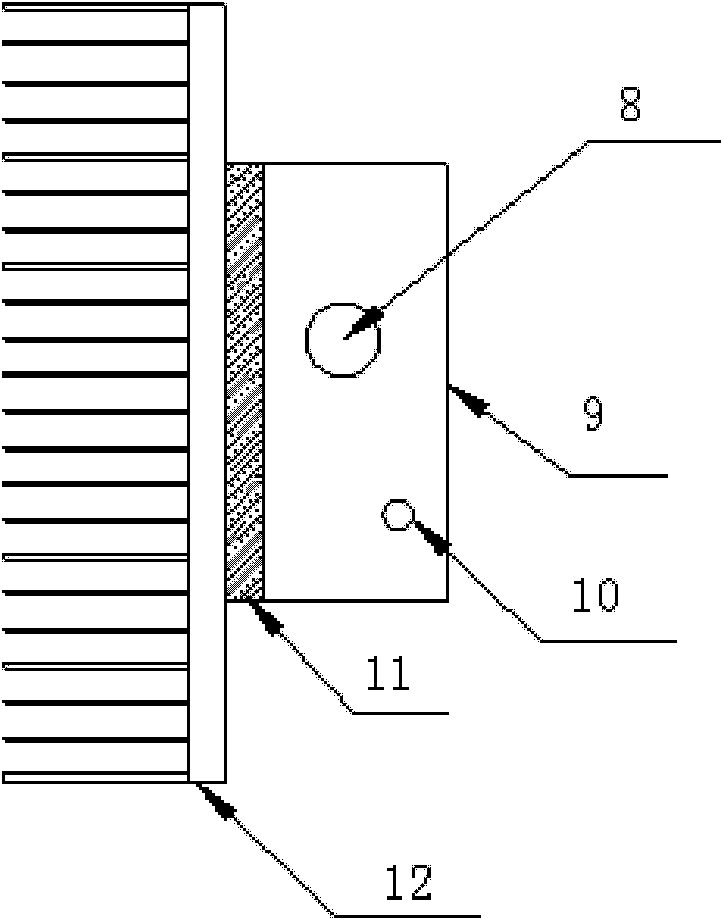

[0025] A thermal purging and trapping apparatus of the present invention comprises a heating furnace 4, a sample furnace 3, a high-purity nitrogen cylinder 1, a transmission pipe 5, a trapping pipe 8 and a refrigeration cold hydrazine 7.

[0026] The sample furnace 3 is made of general-purpose No. 304 stainless steel. The furnace body is cylindrical, with a bottom at one end and a flange opening at the other end. There are 4 fixing bolts evenly around the flange, and the outer diameter of the furnace is 48mm. , wall thickness 4mm; the cover of the sample furnace is also processed by general-purpose 304 stainless steel. The furnace cover has two holes with diameters of 3mm and 6mm respectively. They are fixed by fixing bolts, and there is a high-temperature-resistant gasket between the furnace cover and the furnace body.

[0027] The sample furnace 3 is placed in a heating furnace 4 . The heating furnace 4 is preferably two types: one is a cylindrical resistance wire heating f...

Embodiment 2

[0032] A kind of thermal purging and trapping method utilizing thermal purging and trapping apparatus of the present invention, comprises the following steps successively:

[0033] Step 1, placing the sample to be tested in the sample furnace 3;

[0034] Step 2, the adsorption material is Tenax TA with 80 mesh particles;

[0035] Step 3, using the aluminum block heating furnace 4 to heat the sample furnace 3 at a heating temperature of 180°C;

[0036] Step 4: Turn on the high-purity nitrogen gas and refrigeration cold hydrazine 7, the flow rate of high-purity nitrogen is 80mL / min, the capture time lasts for 30 minutes, and the refrigeration cold hydrazine is kept at -1°C. Transfer Tube Heat: Off.

[0037] The recoveries of the various components were determined in conjunction with automated thermal desorption-GC / MS. C 8~16 The recovery rate of alkanes and m-xylene is greater than 95%, C 17~22 The recovery of alkanes and 2,4-dinitrotoluene was >92%. The sensitivity is bet...

Embodiment 3

[0039] A kind of thermal purging and trapping method utilizing thermal purging and trapping apparatus of the present invention, comprises the following steps successively:

[0040] Step 1, placing the sample to be tested in the sample furnace 3;

[0041] Step 2, the adsorption material is Tenax TA with 80 mesh particles;

[0042] Step 3, using the aluminum block heating furnace 4 to heat the sample furnace 3 at a heating temperature of 320°C;

[0043] Step 4: Turn on the high-purity nitrogen gas and the refrigeration cold hydrazine 7, the high-purity nitrogen flow rate is 30mL / min, the capture time lasts for 30 minutes, and the refrigeration cold hydrazine 7 maintains 6°C. Transfer tube heating: ON, heating temperature is 100°C.

[0044] The recoveries of the various components were determined in conjunction with automated thermal desorption-GC / MS. C 8~16 The recovery rate of alkanes and m-xylene is greater than 98%, C 17~22 The recovery of alkanes and 2,4-dinitrotoluene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com