Dust output control method and control system

An ash conveying and ash hopper technology, applied in the field of ash conveying control method and control system, can solve the problems of high peak flow rate of compressed air main pipe, deterioration of conveying conditions, hardening or arching, etc., so as to reduce maintenance costs, temperature The effect of small reduction, not easy to harden and arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

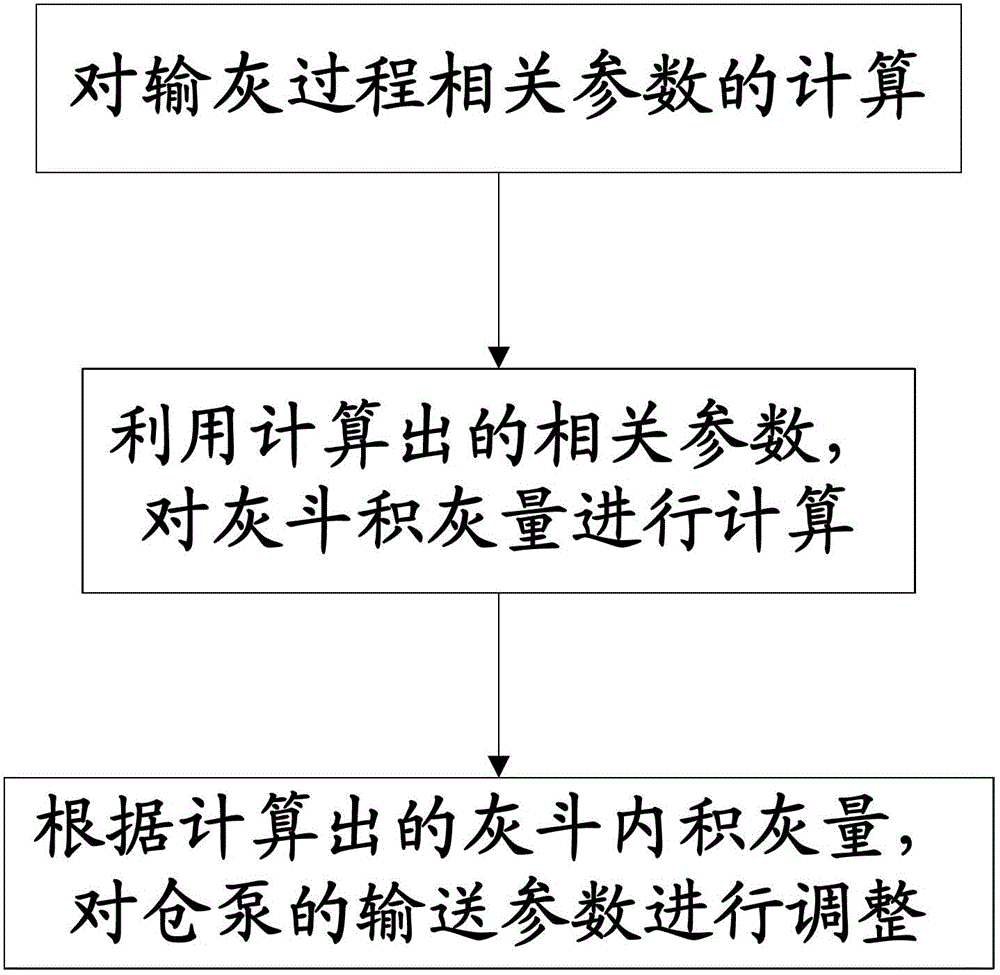

[0026] Such as figure 1 As shown, the control process of the ash conveying control method should be: when the amount of ash accumulated in the ash hopper reaches or approaches the ash amount of the rated conveying capacity of the warehouse pump, the feed valve of the warehouse pump opens, and all the accumulated ash in the ash hopper falls into the bin. pump, so that the ash in the ash hopper is emptied, then, the feed valve is closed, and the bin pump starts to convey.

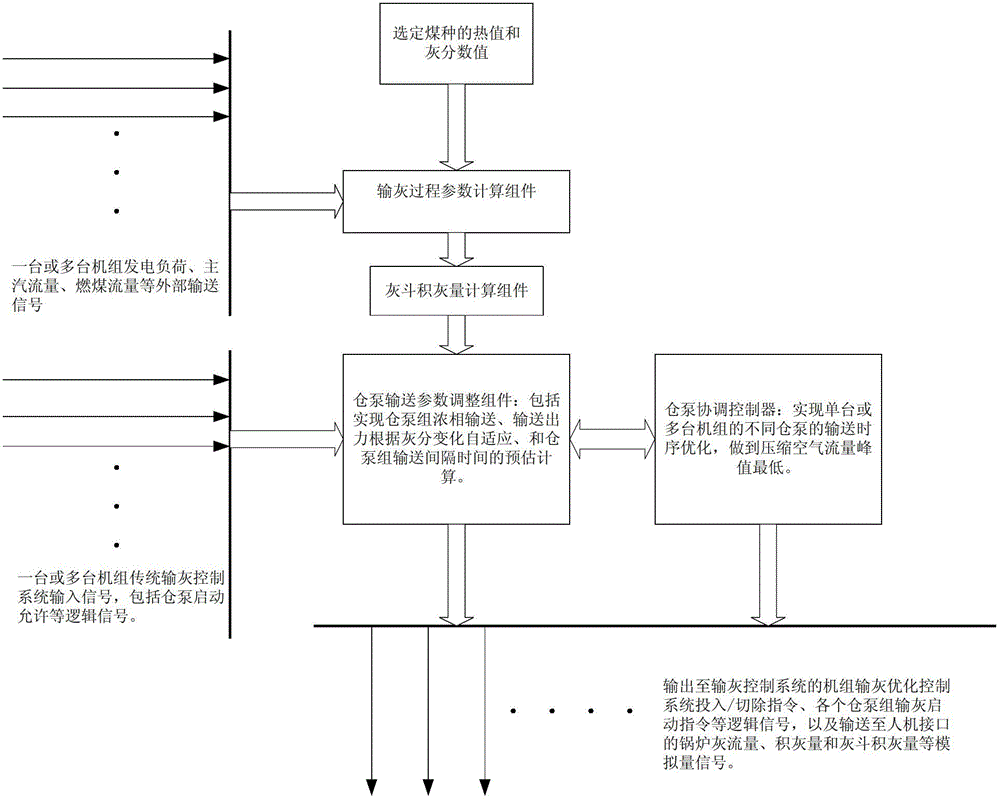

[0027] The present invention realizes the ideal process control of ash conveying by using the relationship among boiler load, coal flow, coal calorific value and coal ash content through field test.

[0028] In the control method of the present invention, proceed according to the following steps:

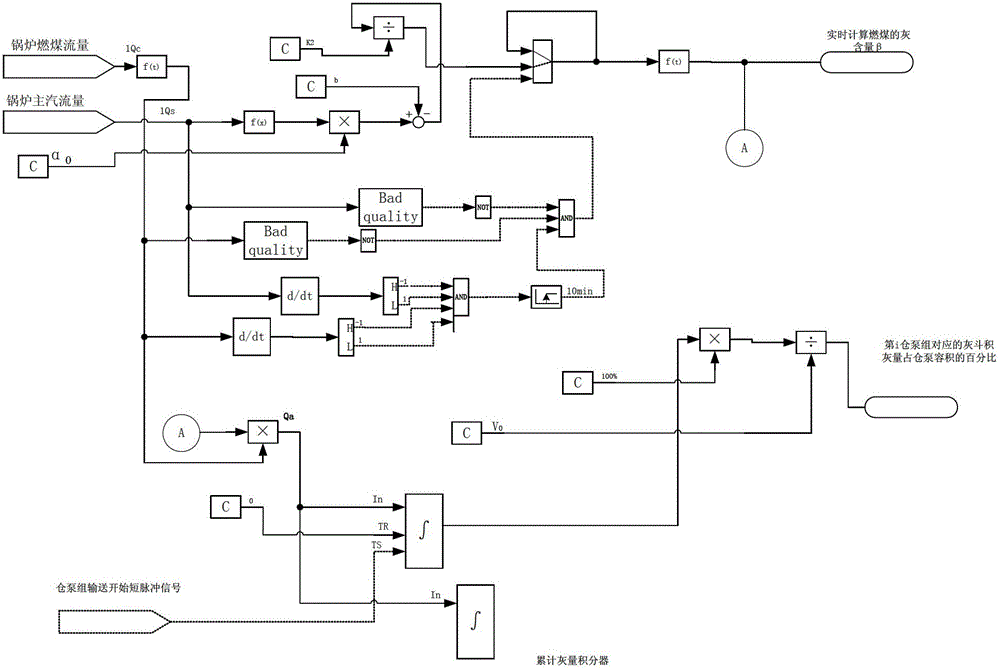

[0029] 1) Theoretical calculation of boiler ash flow and ash accumulation:

[0030] Since the boiler ash flow is equal to the product of the boiler coal flow and the coal ash percentage, the boiler ash accumulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com