Multi-tap composite excitation type controllable reactor

A technology of compound excitation and reactor, applied in the direction of variable inductors, inductors, variable transformers, etc., can solve the problems of reducing system reliability, complex control strategy, increasing loss, etc., to reduce noise, reduce harmonic Wave content and loss, and the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

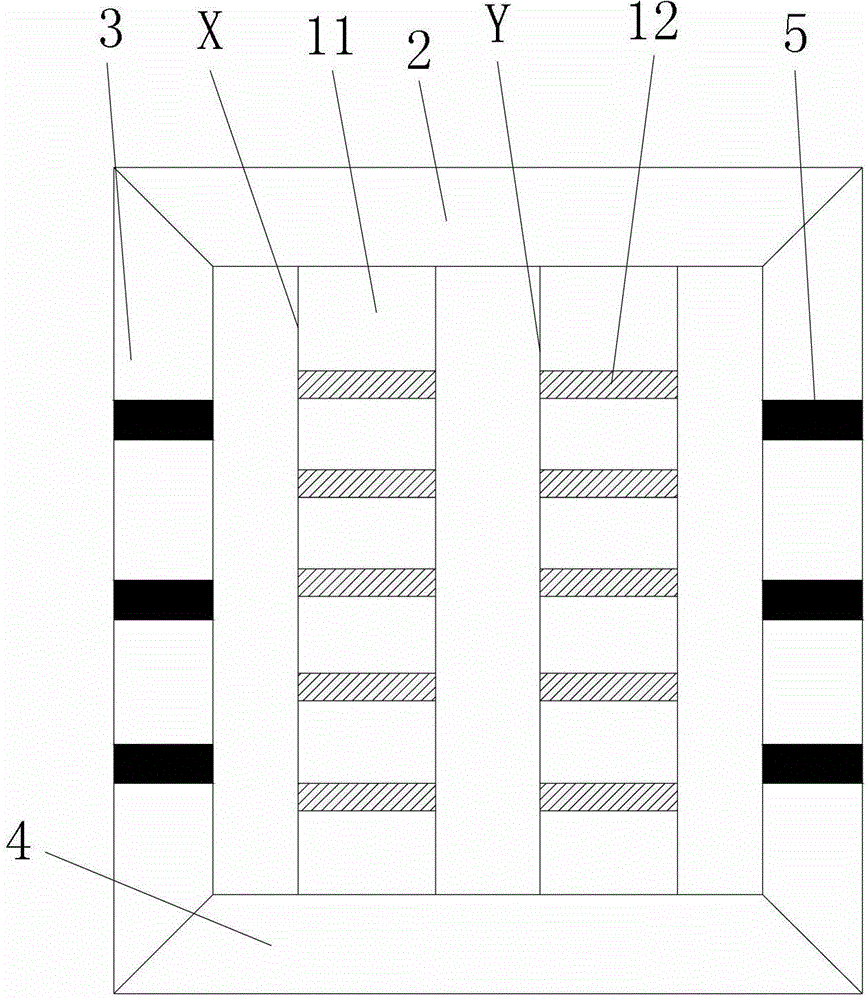

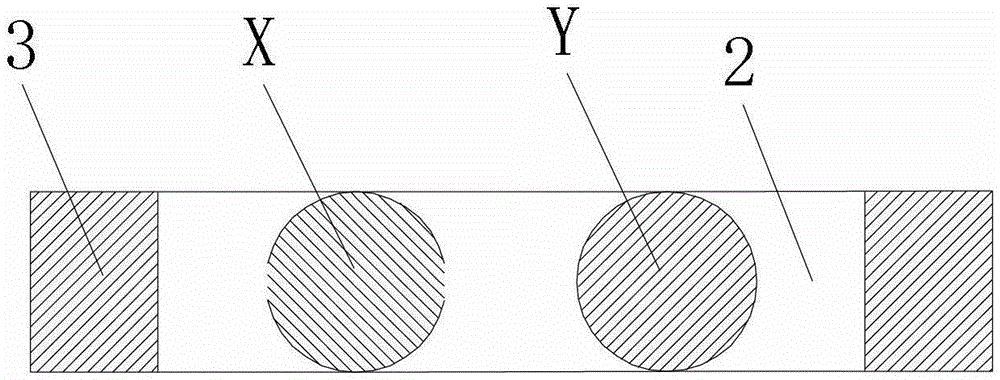

[0051] Such as figure 1 and figure 2 As shown, a multi-tap compound excitation type single-phase controllable reactor has a four-column structure; it includes: an upper yoke 2, a lower yoke 4, two side yokes 3, and a pair of iron cores (X, Y ), the iron core (X, Y) is divided into five sections of discus 11, and the discus 11 of adjacent sections is isolated by magnetic valve 12 (four pieces); the discus is formed by lamination of several silicon steel sheets;

[0052] The side yoke 3 is divided into four sections, and the adjacent sections are separated by air gaps 5 (three groups); the air gaps 5 are filled with epoxy resin, and the total thickness of the three groups of air gaps accounts for 5% of the height of the side yoke; It can prevent the nonlinearity of the reactor when the DC is no-load, so as to avoid the ferromagnetic resonance caused by the nonlinearity of the reactor.

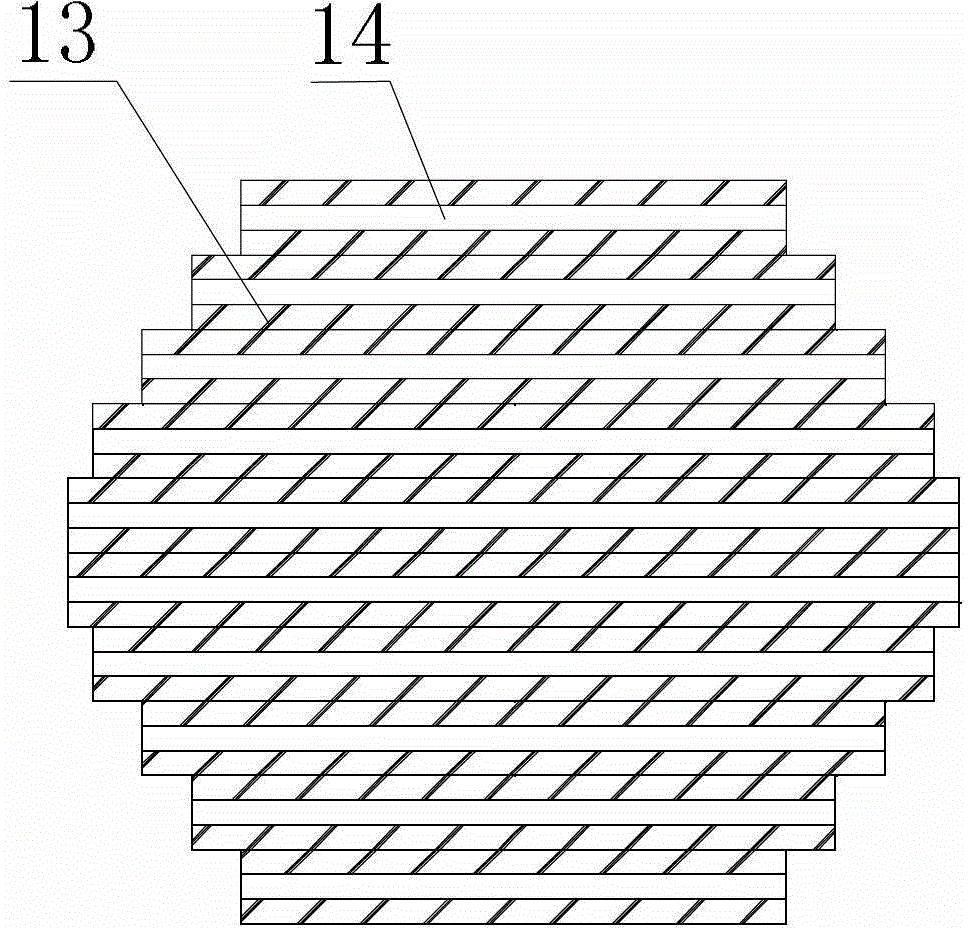

[0053] Such as image 3 As shown, the magnetic valve 12 is composed of a number of silico...

Embodiment 2

[0072] Such as Figure 6 and Figure 7 As shown, a multi-tap compound excitation type three-phase controllable reactor has a six-column structure; it includes: an upper yoke 2, a lower yoke 4, and three pairs of iron cores (X-X', Y -Y', Z-Z'), the iron core is divided into several sections of discus, and the adjacent discus sections are separated by magnetic valves; the discus is made of several silicon steel sheets;

[0073] The magnetic valve is composed of a number of silicon steel sheets and a number of epoxy resin sheets alternately stacked in the horizontal direction; the magnetic valves on the iron core are divided into four categories: magnetic valve A, magnetic valve B, magnetic valve C and magnetic valve D; among them:

[0074] The total area ratio of the magnetically conductive sheet and the magnetically resistive sheet in the cross section of the magnetic valve A is 1:2, and the total thickness of this type of magnetic valve accounts for 28% of the total thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com