Three-dimensional structure metamaterial

A three-dimensional structure and metamaterial technology, applied in the field of three-dimensional structure metamaterials, can solve the problems of low accuracy, high processing cost and process precision control cost, and difficult microstructure processing process, so as to achieve simple process precision control and preparation The effect of simple process and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

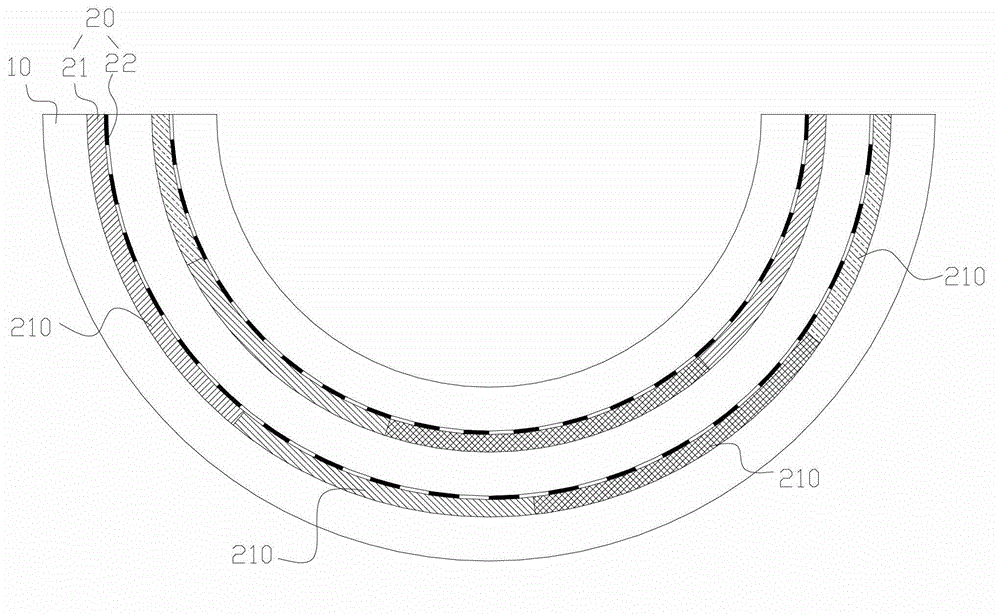

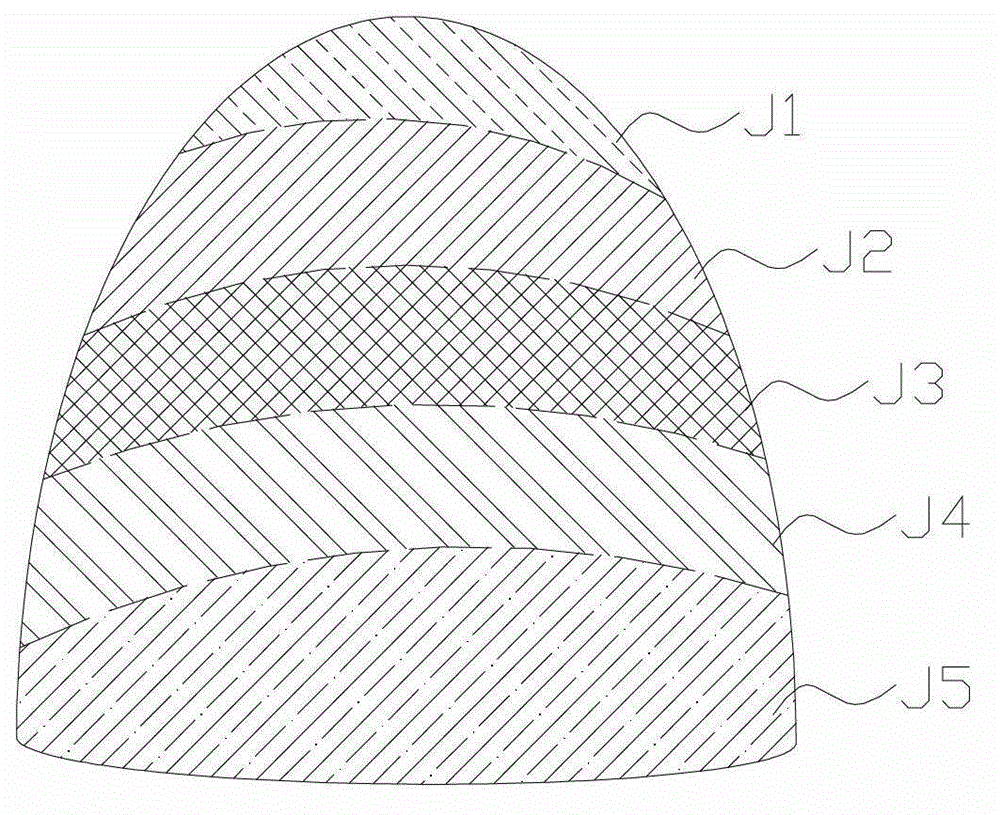

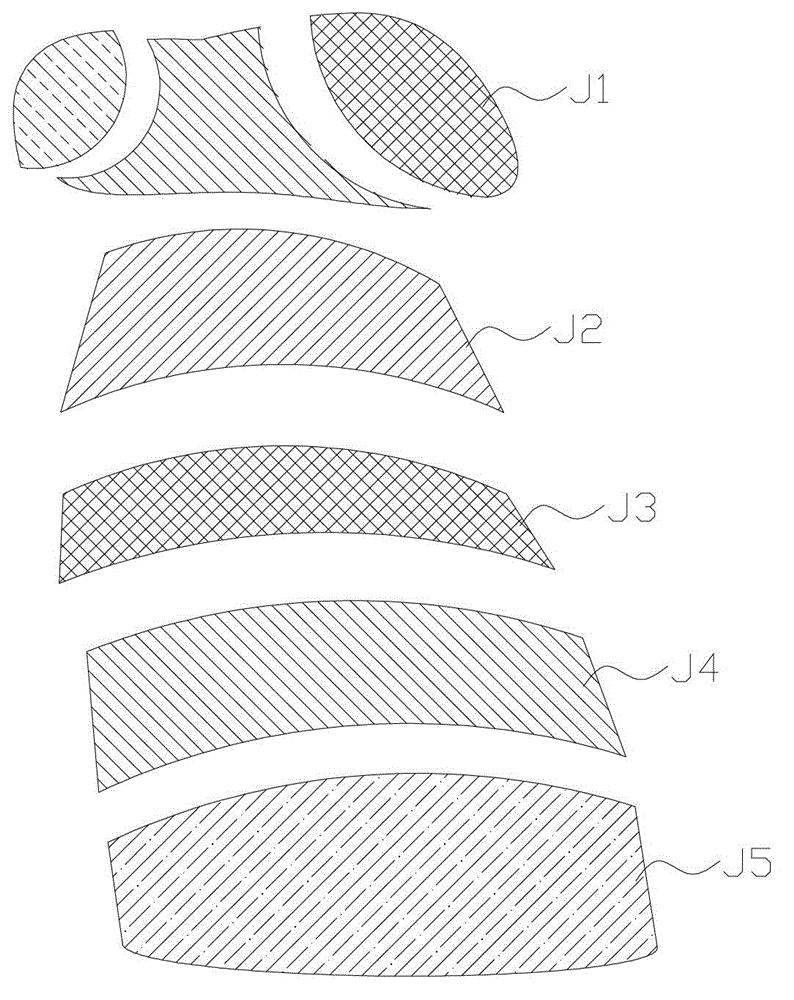

[0065] Please refer to figure 1 , figure 1 It is a partial cross-sectional schematic diagram of a preferred embodiment of the three-dimensional structure metamaterial of the present invention. figure 1 Among them, the three-dimensional structural metamaterial includes a multi-layer molding substrate 10, a flexible functional layer 20 that is closely attached to the surface of the molding substrate 10, and the flexible functional layer includes a flexible substrate 21 composed of at least one flexible sub-substrate 210 and arranged on each A plurality of artificial microstructures 22 capable of responding to electromagnetic waves on a flexible sub-substrate 210; the three-dimensional structural metamaterial has the function of electromagnetic wave modulation.

[0066] In an embodiment of the present invention, the three-dimensional structural metamaterial may include at least two layers of flexible functional layers and at least two layers of molding substrates. In a preferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com