Method for purifying cadmium-containing paddy soil

A cadmium paddy field and soil technology, applied in the restoration of polluted soil, separation method, improvement of process efficiency, etc., can solve problems such as inability to install drainage treatment devices, high cost, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

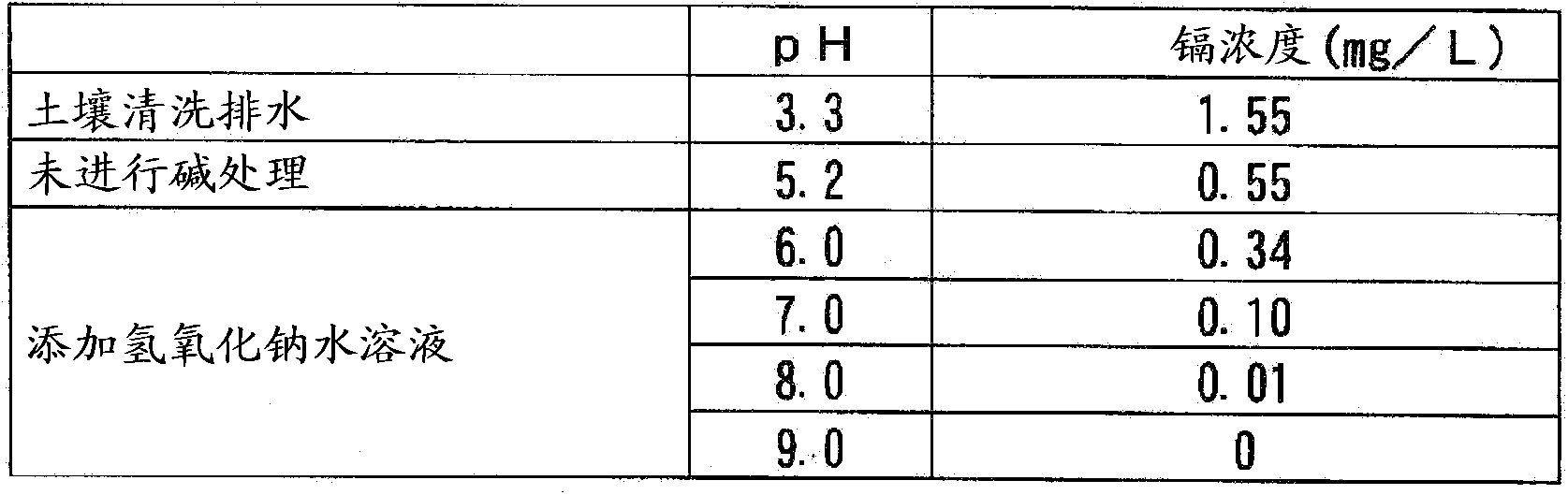

[0053] Weigh 2000g of cadmium-containing air-dried paddy field soil, put it into a 5000mL tank, add 4000mL of 20mM ferric chloride solution, stir it with a three-one motor (Three-One Motor) for 1 hour, let it stand still, and recover the supernatant. Think of it as a "soil wash drain". The pH of "soil cleaning and drainage" is 3.3, and the concentration of cadmium: 1.55mg / L.

[0054] Weigh 50g of cadmium-containing air-dried paddy field soil in a 200mL beaker, add 100mL of "soil washing and drainage", and add aqueous sodium hydroxide solution in multiple stages. Further, after stirring for 10 minutes with a magnetic stirrer, the soil was allowed to stand still, the soil was allowed to settle, the supernatant water was collected, and the pH and cadmium concentration were measured. In addition, the case where only cadmium-containing air-dried paddy field soil and soil washing drainage were treated in the same manner without using an aqueous sodium hydroxide solution is shown as...

Embodiment 2

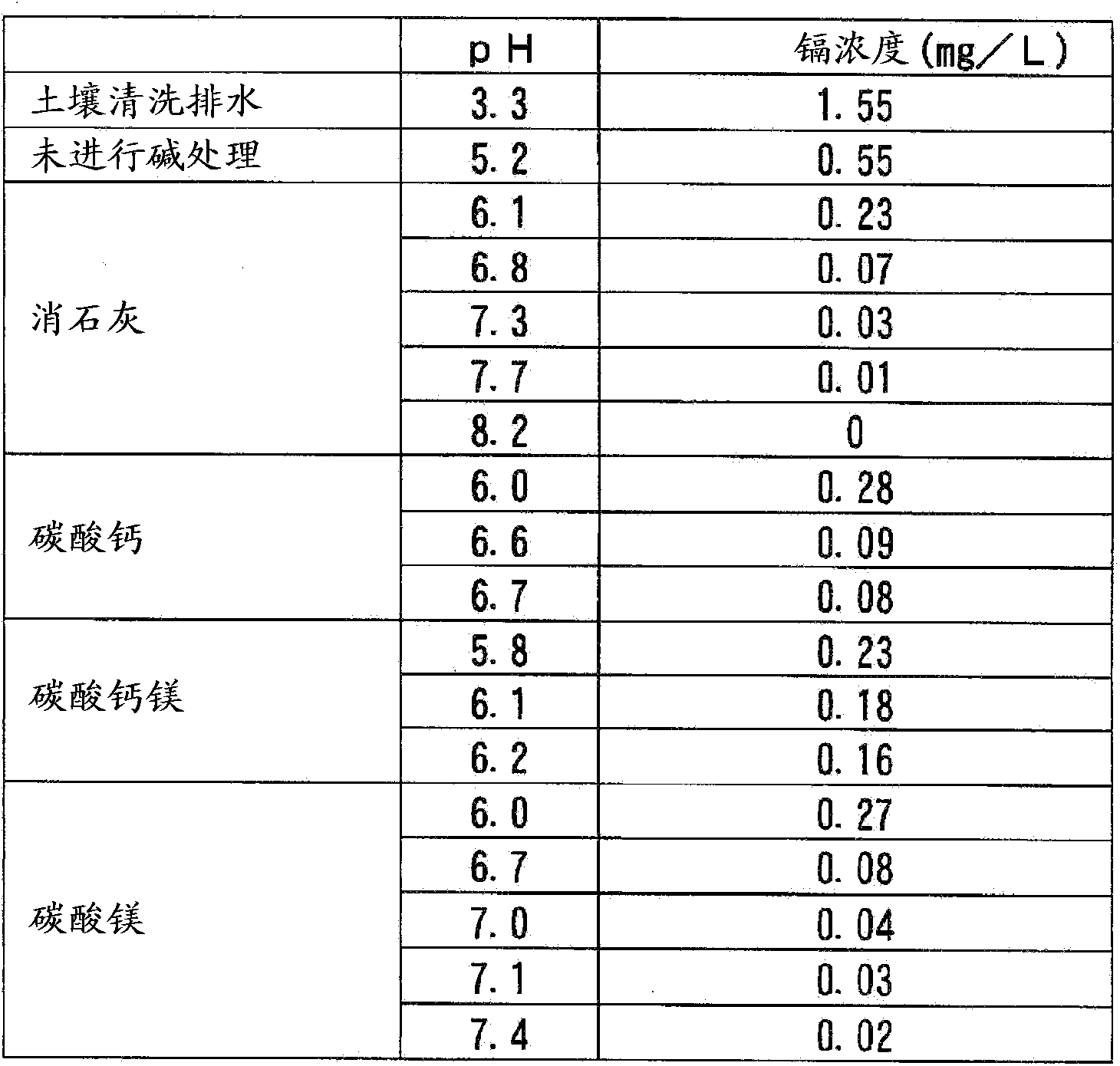

[0058] Weigh 50g of air-dried paddy field soil in multiple 200mL beakers, and add 100mL of "soil washing and drainage" prepared in Example 1 respectively. 50 to 250 mg of various basic materials were added to each beaker. Shake and stir for 10 minutes, let the soil settle, and measure the pH and cadmium concentration of the supernatant water. The results are shown in Table 2.

[0059] Table 2:

[0060]

Embodiment 3

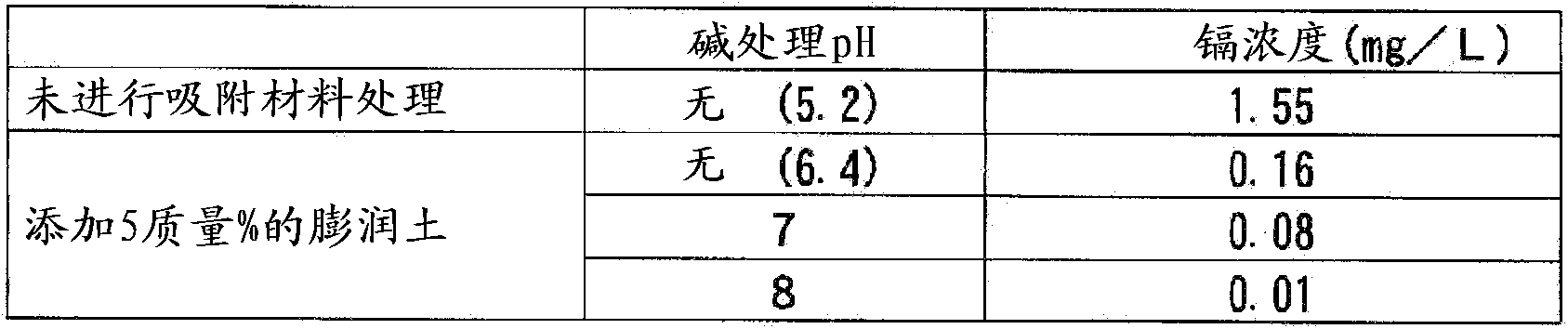

[0062] Weigh 50 g of air-dried paddy field soil into multiple 200 mL beakers, add 2.5 g (5% by mass relative to the air-dried paddy field soil) of bentonite, and stir and mix with a glass rod. Add 100 mL of "soil washing and drainage" prepared in Example 1 respectively, and add an appropriate amount of sodium hydroxide aqueous solution, shake and stir for 10 minutes, and adjust to pH7 or pH8. Thereafter, the soil was allowed to stand still, and the cadmium concentration in the supernatant water was measured. The results are shown in Table 3.

[0063] table 3:

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com