Deashing device for SCR flue gas denitration system

An ash cleaning device and denitrification technology, applied in the field of air pollutant control, can solve the problems of shortening the catalyst life, increasing the weight of the reactor, blocking the flow of flue gas, etc., so as to improve the overall economic benefit, reduce the operating cost, and increase the sedimentation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

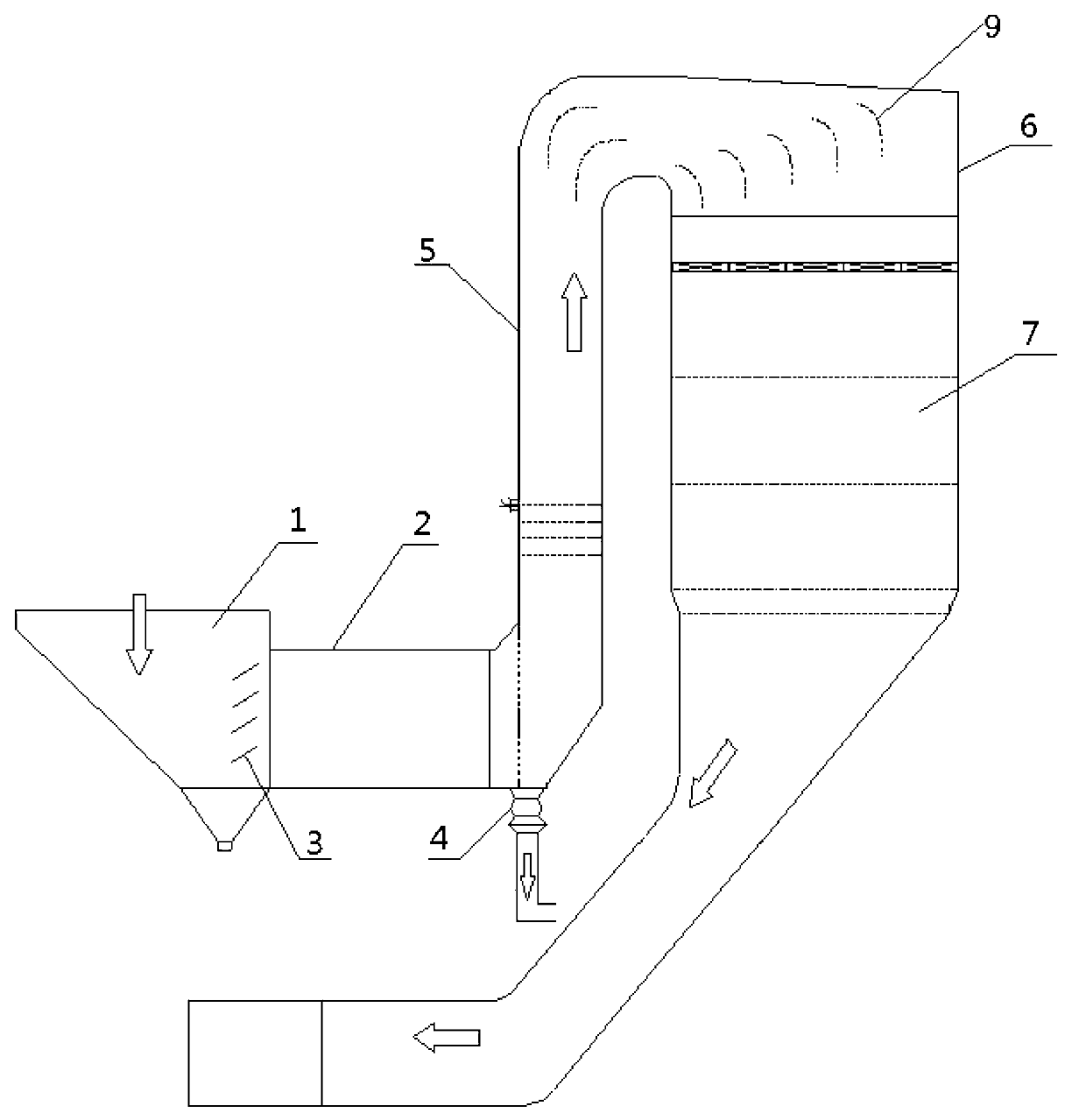

[0017] Ash cleaning device in SCR flue gas denitrification system ( figure 1 ), including the front ash hopper 1 and the catalyst bed 7, the catalyst bed 7 is placed in the shell 6, and the deflector 9 is arranged in the shell 6, and the front ash hopper 1 passes through the horizontal flue 2 and the ascending flue 5 It communicates with the shell 6, the ash baffle 3 is arranged at the junction of the front ash hopper 1 and the horizontal flue 2, the flue gas outlet of the economizer is connected with the front ash hopper 1, and the ascending flue 5 and the horizontal flue 2 The inner bottom of the junction is provided with an air-lock powder feeder 4 . The air-lock powder feeder 4 is connected with the dust collector through the pipeline, and the dust accumulation is regularly removed.

Embodiment 2

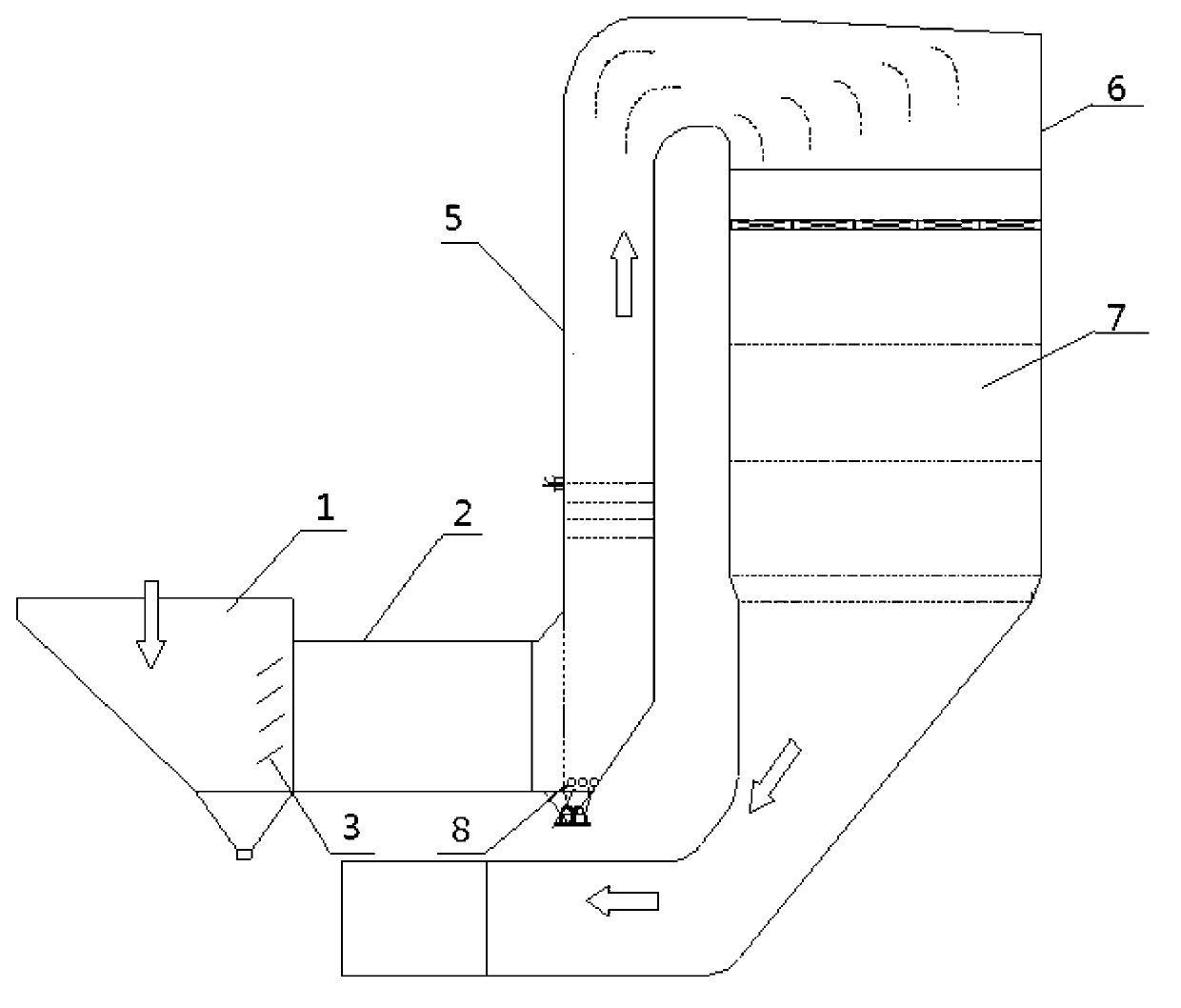

[0019] Ash cleaning device in SCR flue gas denitrification system ( figure 2 ), including the front ash hopper 1 and the catalyst bed 7, the catalyst bed 7 is placed in the shell 6, and the deflector 9 is arranged in the shell 6, and the front ash hopper 1 passes through the horizontal flue 2 and the ascending flue 5 It communicates with the shell 6, the ash baffle 3 is arranged at the junction of the front ash hopper 1 and the horizontal flue 2, the flue gas outlet of the economizer is connected with the front ash hopper 1, and the ascending flue 5 and the horizontal flue 2 A soot blowing pipe 8 is provided at the inner bottom of the junction. The soot blowing pipe 8 regularly blows soot, and the gas source is air or steam or a mixture of air and steam.

[0020] The cross-sectional size of the traditional ash hopper inlet is 8535mm×6620mm, and the cross-sectional size after expansion is 11945mm×9265mm; the size of the traditional horizontal flue is 3800mm×5800mm, and the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com