Soldering flux suction nozzle

A flux and straw technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of mechanical failure and easy to be stuck, and achieve the effect of safe and convenient use, good recovery effect and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the present invention more specifically, the present invention will be further described below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to this embodiment.

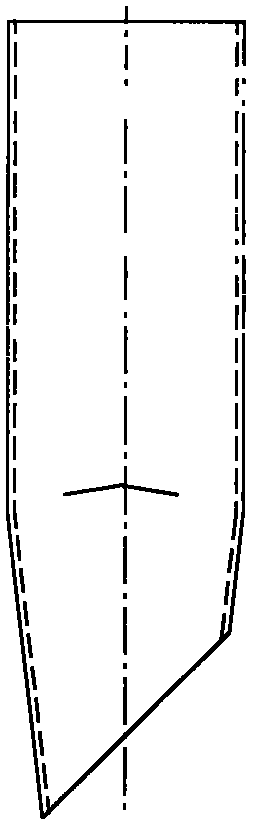

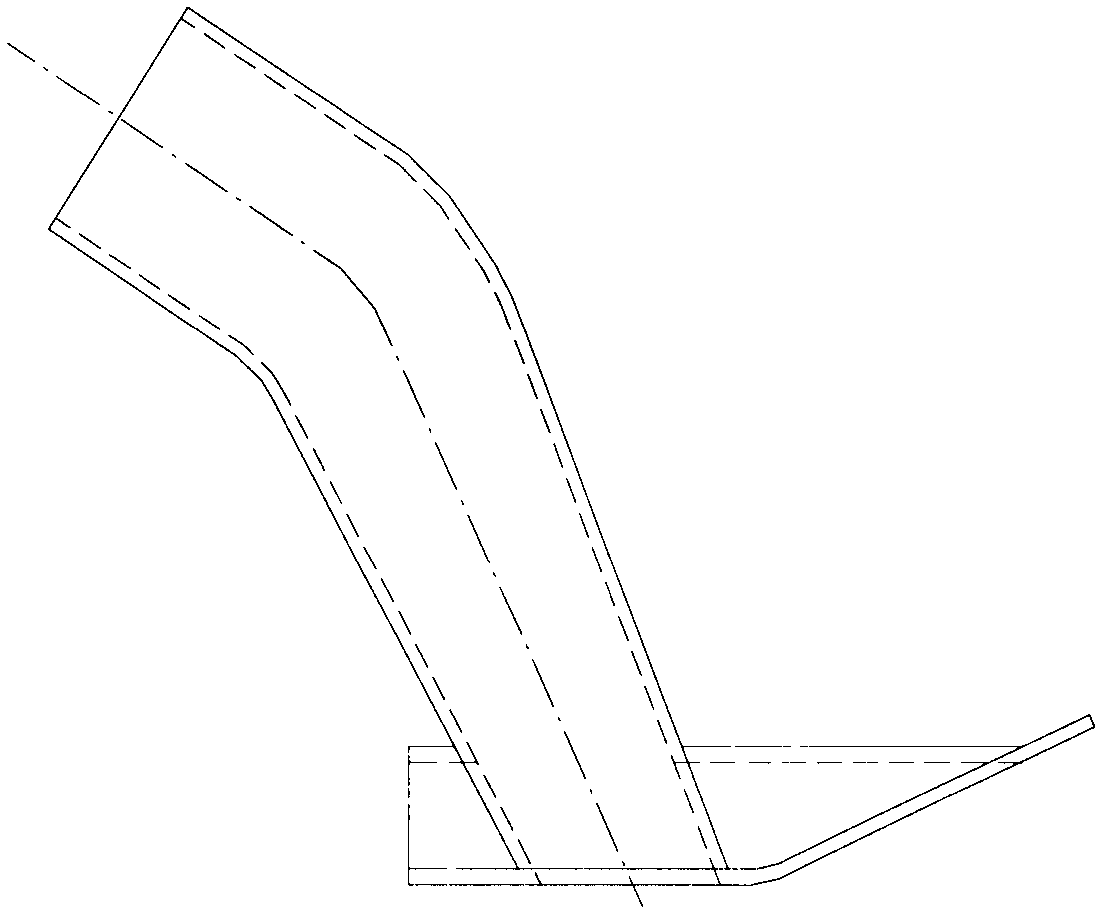

[0015] combine figure 2 It can be seen that the front end of the suction nozzle of the present invention is leaning forward. When encountering a protrusion or an obstacle, the flexibility of the hose can make the suction nozzle climb up the protrusion or obstacle and then cross the obstacle. It is in the shape of a bridge arch and imitates the shape of the weld seam to ensure that the useful flux can be recovered as much as possible without touching the weld seam. The suction port is arranged in the middle and rear of the bridge arch. The suction pipe can be connected to the flux rubber hose at a certain angle behind ( Such as figure 2 ).

[0016] This nozzle is especially suitable for installation at the end of the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com