Electron beam welding method of gas turbine casing with horizontal flange structure

A technology of electron beam welding and gas turbine, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex design and manufacture of tooling, low rate of reuse of tooling, and low production efficiency, and achieve small deformation and high production efficiency. Improved efficiency and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

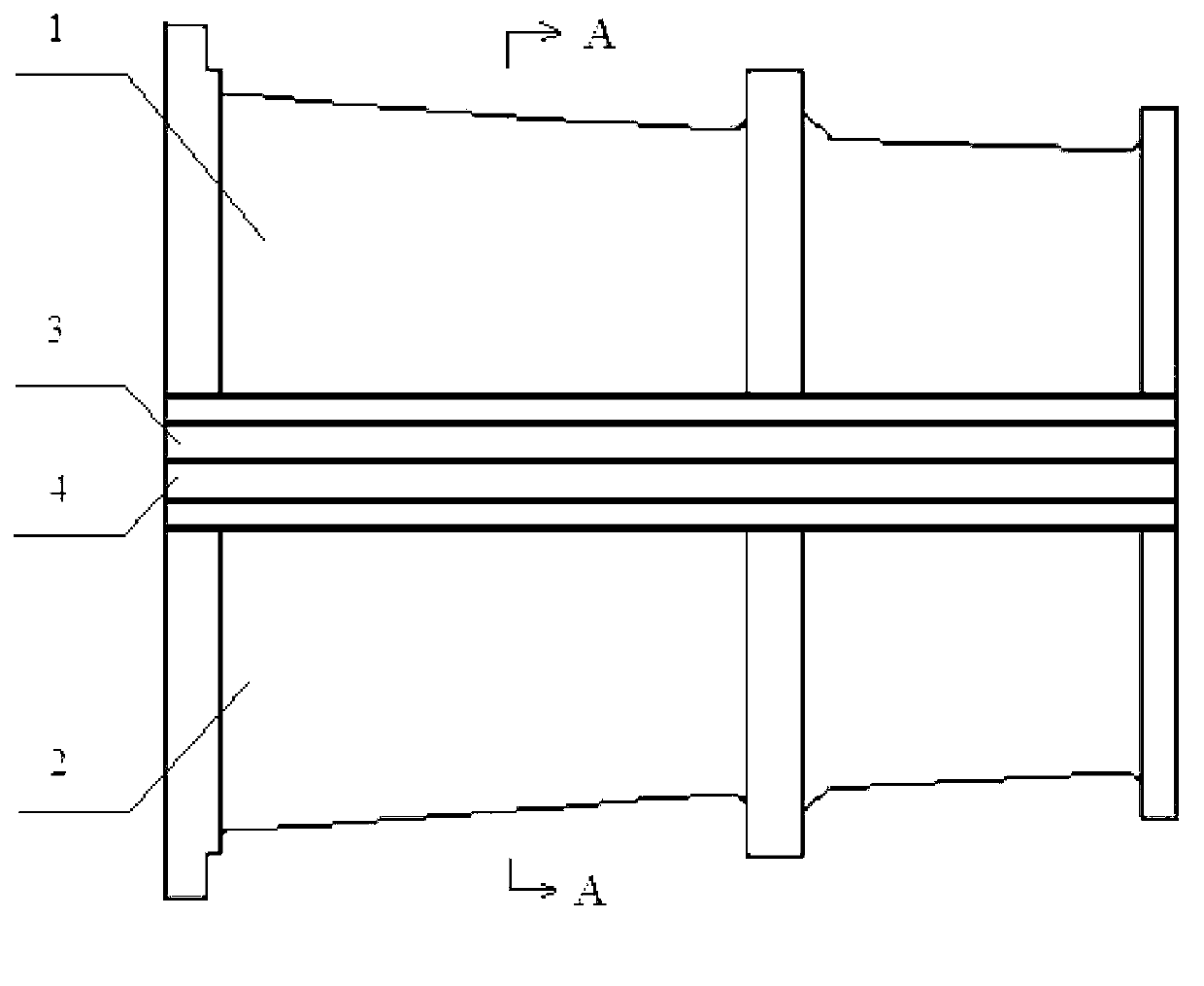

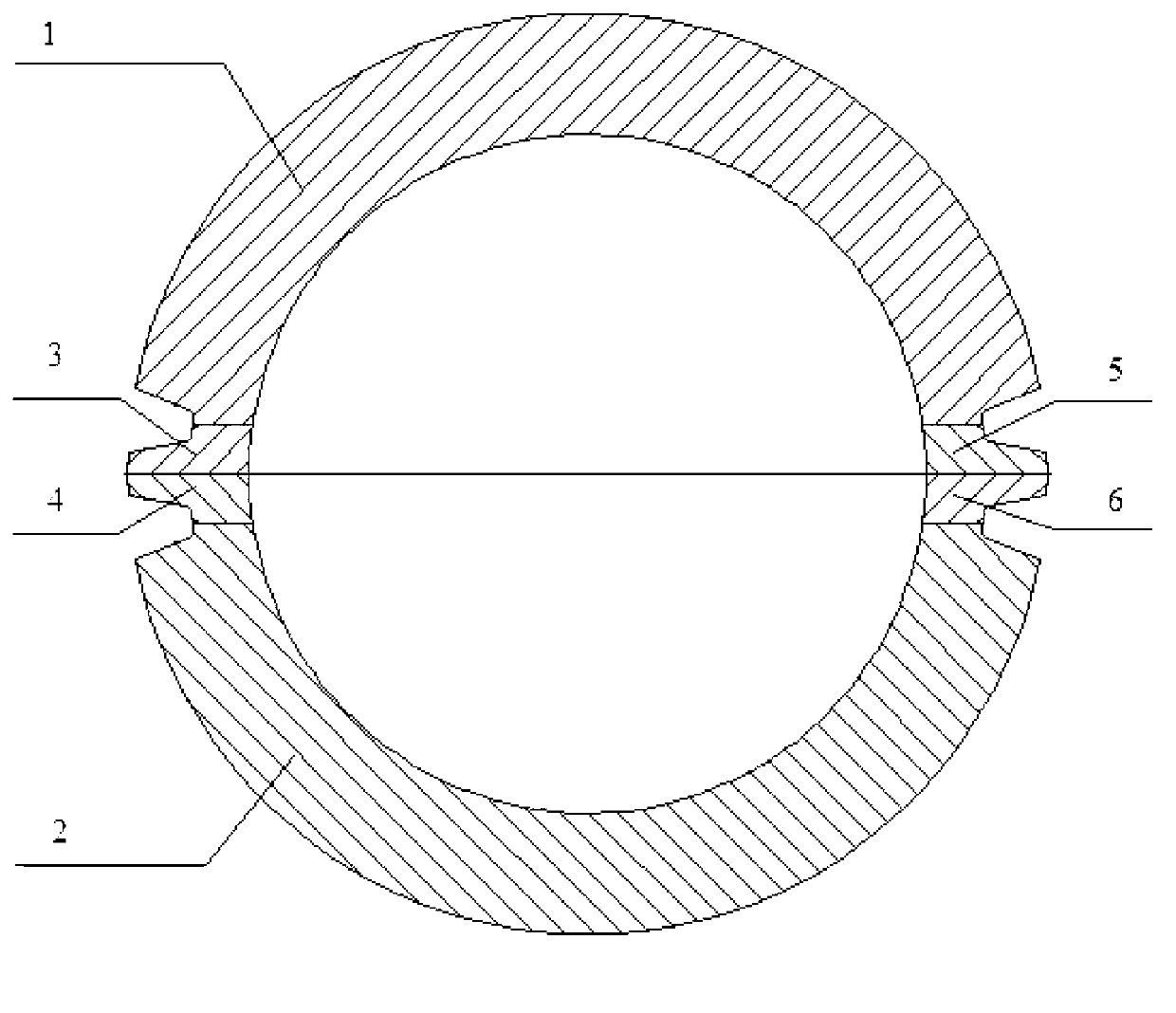

[0018] Specific Embodiment 1: An electron beam welding method for a gas turbine casing with a horizontal flange structure in this embodiment is implemented in accordance with the following steps:

[0019] 1. Machining: Machining an opening groove inlaid with a pair of horizontal flanges on the casing body, after rotating the casing body 180°, machining an opening groove inlaid with a pair of horizontal flanges at the corresponding position to ensure The symmetry of the two grooves, the width of the opening groove is twice the height of a single horizontal flange, the length of the opening groove is the length of the horizontal flange, and there is a margin of 8~12mm between the two ends of the opening groove and the two ends of the casing body;

[0020] 2. Cleaning: Clean the surface of the casing body to be welded and the surface of the horizontal flange to be welded;

[0021] 3. Spot welding: Spot welding two or two pairs of horizontal flanges on the outer surface of the hor...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, there is a margin of 10 mm between the two ends of the opening slot and the two ends of the casing barrel, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 5, the gap between the horizontal flange and the casing body is 0.05-0.12 mm, and the wrong side is 0.02-0.08 mm. Other steps and parameters are the same as The specific embodiment 1 or 2 are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com