Pleated paper off-line slitter machine for undulant filter

A filter and wave-shaped technology, which is applied in the field of processing equipment for wave-shaped filters, can solve the problems of poor cutting precision of the cloth cutter, uneven end faces of pleated paper, and low efficiency of filter elements, so as to achieve a wide range of use and ensure uniformity. , The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

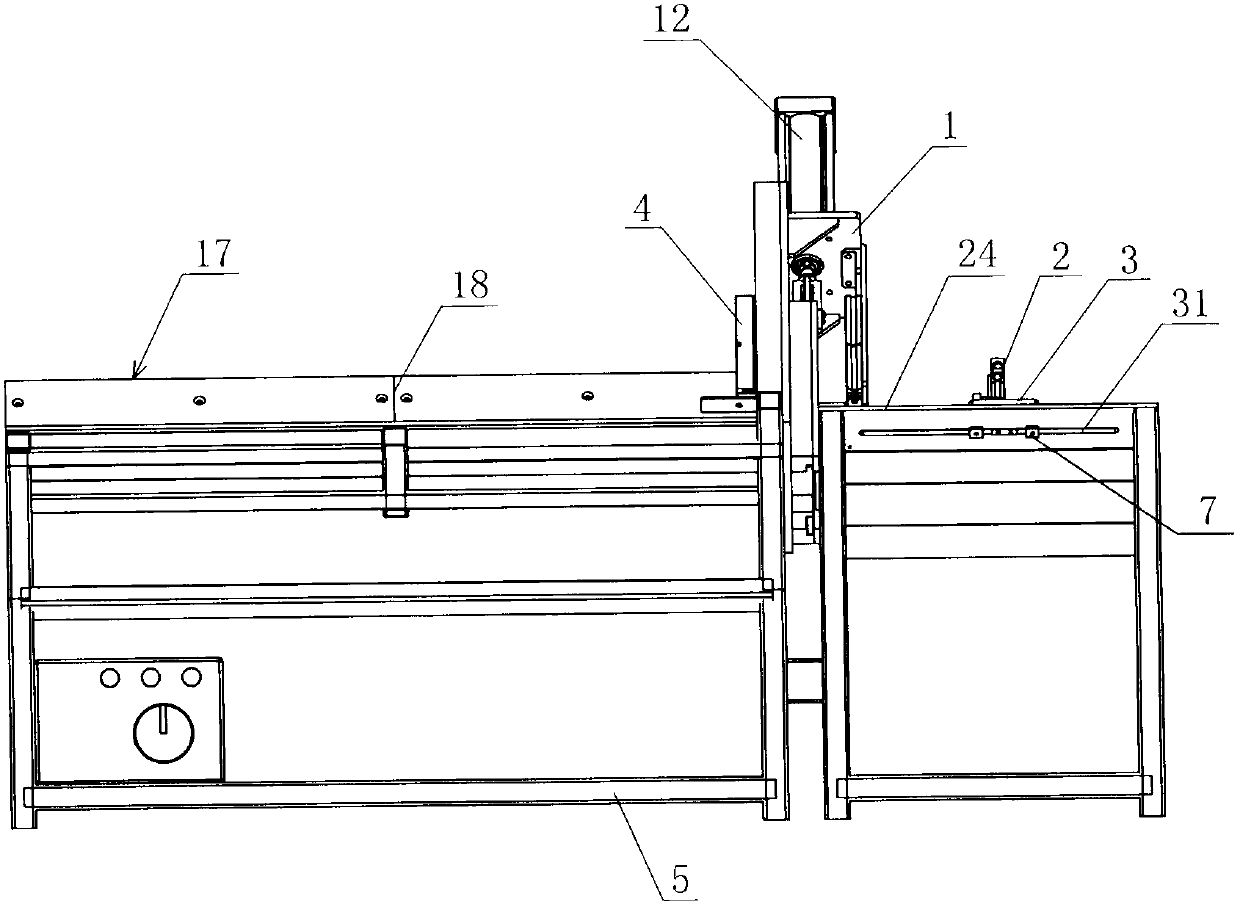

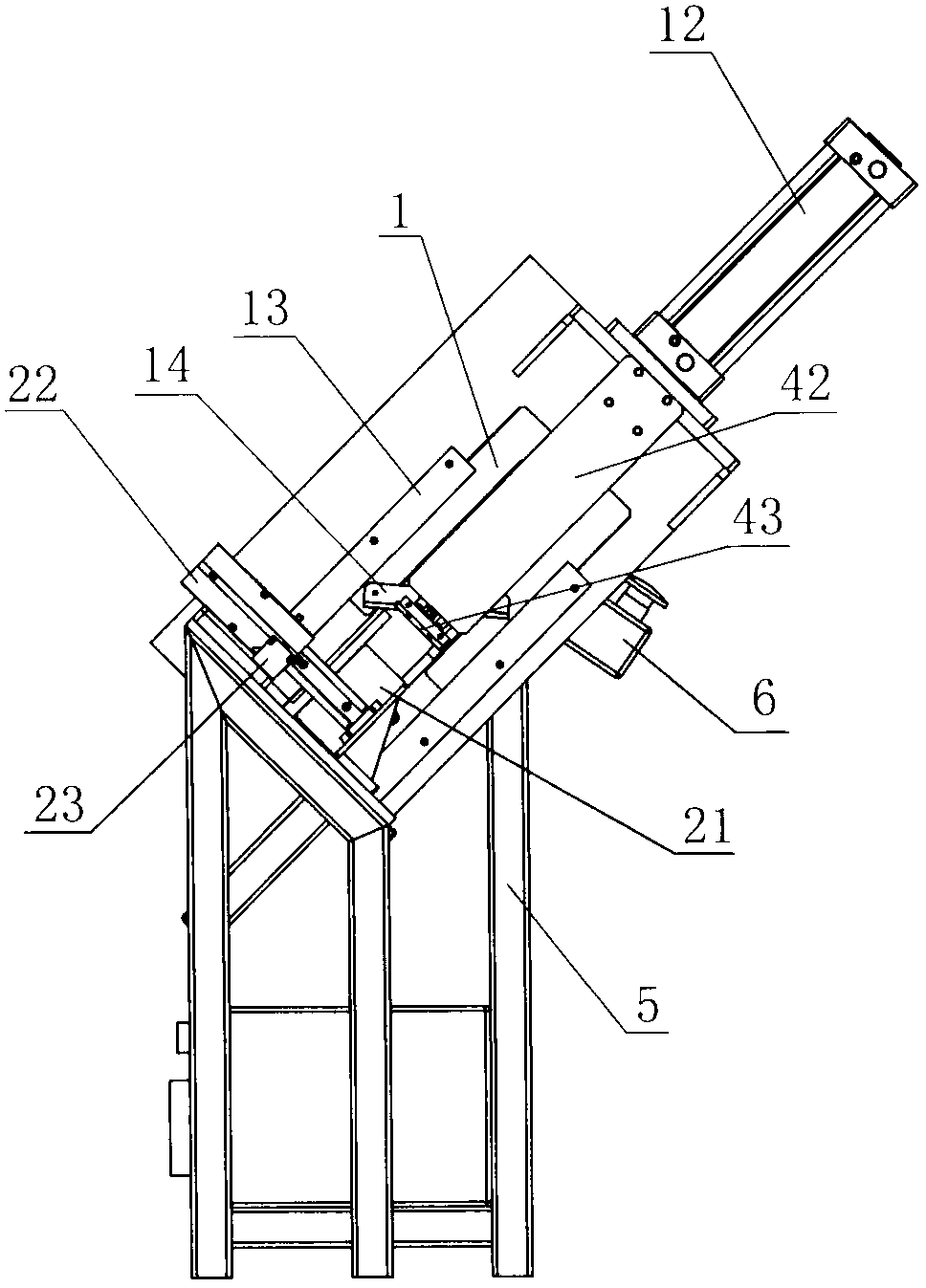

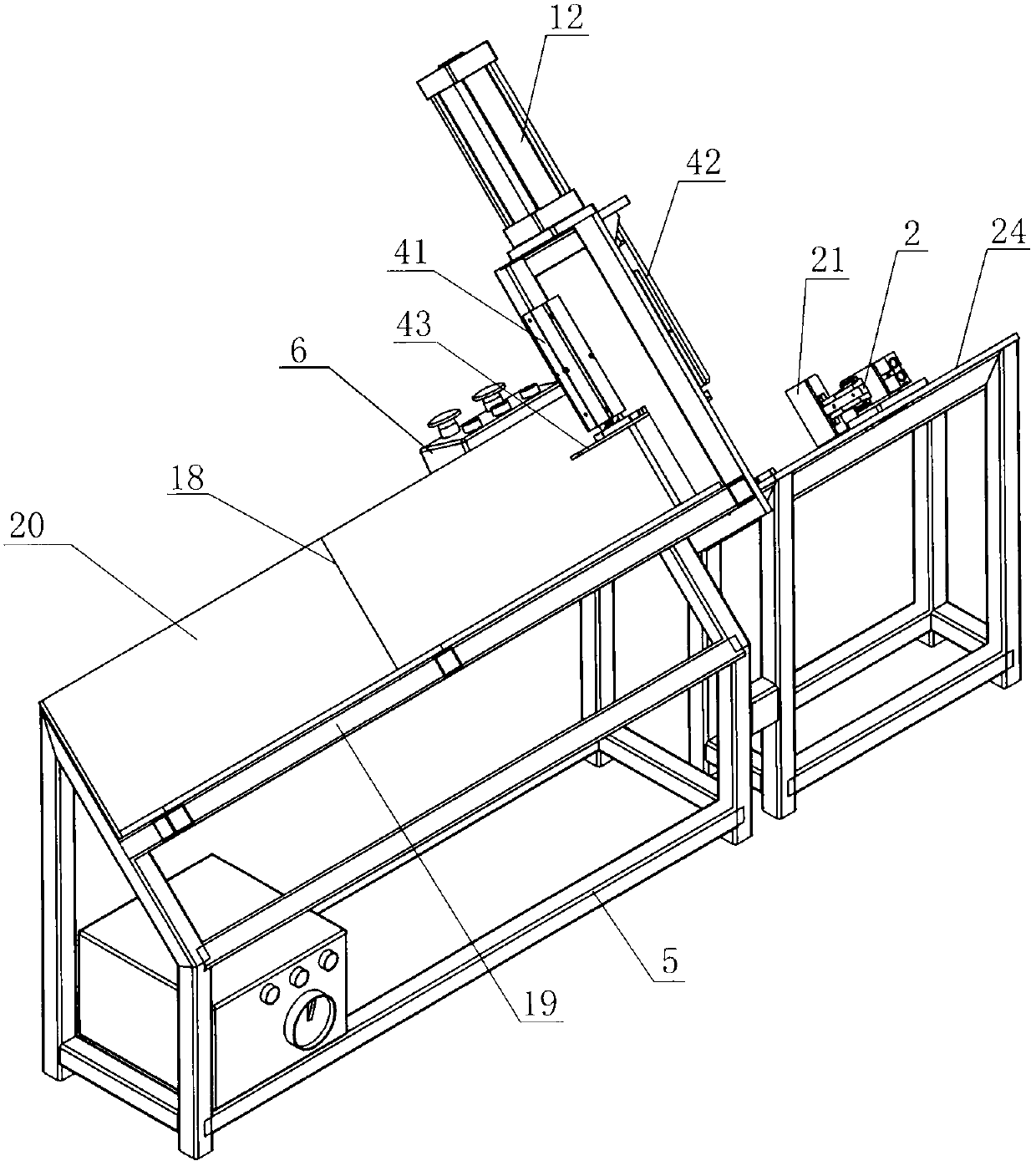

[0031] Embodiment one: see Figure 1-7 As shown, a pleat paper off-line slitting machine for wave-shaped filters includes a frame, a cutter mechanism 1 arranged on the frame, a positioning assembly 2, a controller 6, a paper pressing mechanism 4, and a limit assembly. The frame is made up of a base 5 and a work platform with a 45° slope to the horizontal plane, and the controller 6 is installed on the frame.

[0032] Such as Figure 1-7 As shown, the cutter mechanism 1 is located in the middle of the working platform, and is mainly composed of a cutter door frame 11, a door frame driver 12, a sliding track 13 and a cutter 14. The cutter door frame 11 is U-shaped, and the The two ends of the cutter 14 bridge over the opening end of the U-shaped cutter door frame 11, and the two sides of the cutter door frame 11 are slidably connected in the sliding track 13, and the sliding track 13 is vertically fixed on the working platform The door frame driver 12 is composed of a cylinder, ...

Embodiment 2

[0047] Embodiment 2: An off-line slitting machine for pleat paper for wave-shaped filters. In this embodiment, its structure is basically similar to that of Embodiment 1, except that the gate driver is composed of a gas-hydraulic pressurized cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com