Method and device for removing algae by applying micro-bubble air flotation of multiphase flow pump

A multi-phase flow pump and micro-gas technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of unstable operation, dosing of coagulant, low removal efficiency, etc., and achieve high operation stability, rapid removal, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below through examples.

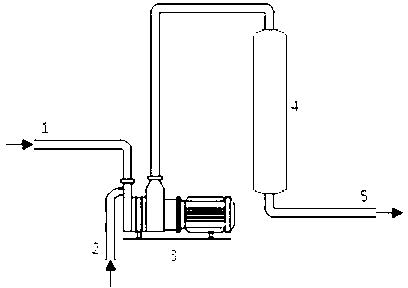

[0034] as attached figure 1 As shown in the structural schematic diagram of the device of the present invention, a device for removing algae by micro-air flotation using a multiphase flow pump is used to generate dissolved air water, and is detachably installed on a mobile or fixed platform and support, including a water inlet pipe 1. The intake pipe 2, the multiphase flow pump 3, the dissolved air tank 4 and the outlet pipe 5, the water inlet pipe 1 and the intake pipe 2 are connected to the multiphase flow pump 3, and the multiphase flow pump 3 is connected to the dissolved air tank 4 to generate The dissolved air water is discharged from the outlet pipeline 5 through the dissolved air tank 4. in:

[0035] The multiphase flow pump 3 is a rotary power multiphase flow pump or a volumetric multiphase flow pump, and can be a single pump or multiple pumps connected in parallel.

[0036] The dissolved a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com