Preparation method of MnZn (Manganese-Zinc) soft magnetic ferrite material containing modified tree ash

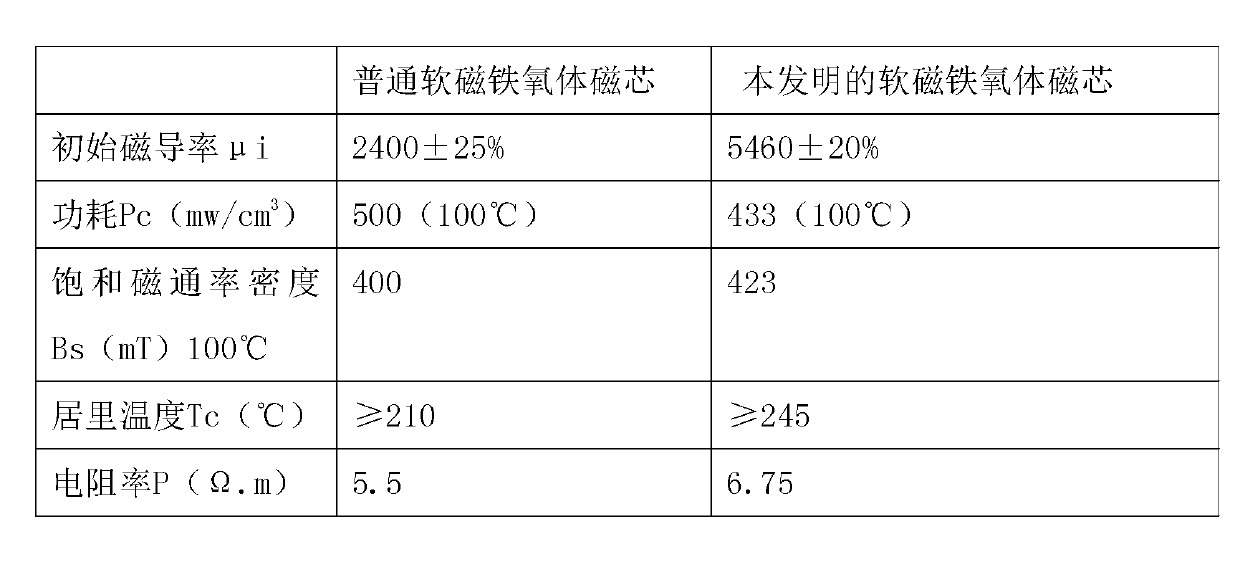

A technology of soft magnetic ferrite and tree ash, which is applied in the direction of magnetic properties of inorganic materials, can solve problems such as loss, frequency characteristics, and unsatisfactory Curie temperature, and achieve the effects of good raw material distribution, high DC superposition characteristics, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation method that contains the manganese zinc MnZn soft magnetic ferrite material of modified tree ash, comprises the following steps:

[0021] (1) Ingredients: Fe in molar ratio 2 o 3 52mol, MnO 34.2mol, ZnO 13.5mol, iron powder 0.15mol and Co2O3 0.15mol for batching;

[0022] (2) Auxiliary materials: equivalent to 0.025wt% modified tree ash and 0.008wt% MoO 3 , 0.035wt% V 2 o 5 , 0.025wt% Bi 2 o 3 and 0.03wt% ZrO 2 ; The modified tree ash is prepared by the following method:

[0023] a. After soaking the tree ashes with 10% sodium hydroxide solution for 2-3 hours;

[0024] b. Soak in 10% hydrochloric acid solution for 2-3 hours;

[0025] c. Wash with deionized water several times until the tree ash is neutral, then dry;

[0026] d. Grinding to 0.9 μm powder to obtain modified tree ash;

[0027] (3) Pre-calcination: add water and dispersant to the main material prepared in step (1) and perform ball milling for 3-4 hours, then spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com