Synthetic method of fluoro ethylene carbonate

A technology of fluoroethylene carbonate and chloroethylene carbonate, which is applied in the field of catalytic synthesis, can solve problems such as the need to increase the yield, and achieve the effects of easy realization, high reaction yield, and abundant sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

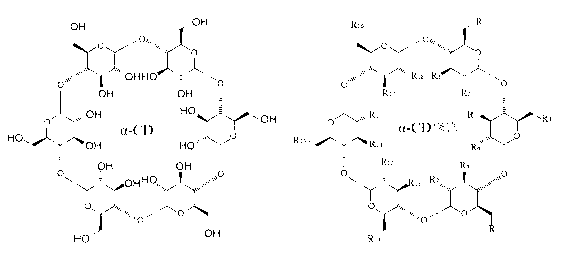

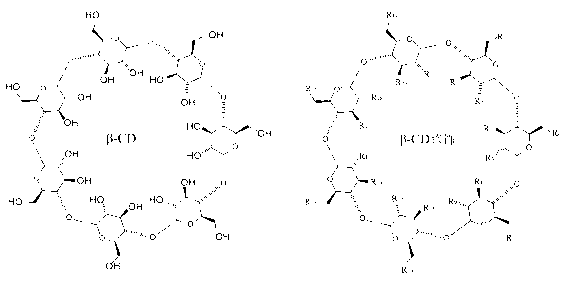

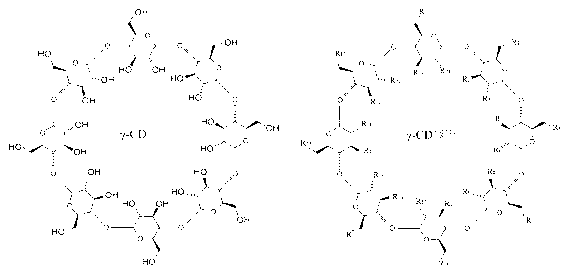

[0029] Add 500g of chloroethylene carbonate and 1000g of N,N-dimethylformamide (DMF) to a 2000ml four-neck round bottom flask equipped with mechanical stirring, thermometer and reflux condenser, stir and mix well, then add 357g of KF solid and 1.5 g β-cyclodextrin. Heat up to 30°C in an oil bath. After 3 hours of heat preservation and reaction, filter. After washing the filter cake with DMF, 1632g of filtrate was obtained. The solution was analyzed, and the mass of fluorinated ethylene carbonate (FEC) in the filtrate was measured by gas chromatography to be 404.7g, and the yield of FEC reached 93.5%.

Embodiment 2

[0031] In the 2000ml four-necked round-bottom flask that is equipped with mechanical stirring, thermometer, reflux condenser, add 500g chloroethylene carbonate and 500g N,N-dimethylformamide (DMF) and 500g acetonitrile, after stirring and mixing, 476 g of KF solids were added along with 5.0 g of α-butyl-cyclodextrin. Heat up to 40°C in an oil bath. After 3 hours of heat preservation and reaction, filter. This solution was analyzed, and the quality of FEC contained in the filtrate was 406.6g as measured by gas chromatography. The yield of the final product FEC reached 93.9%.

Embodiment 3

[0033] Add 500g of chloroethylene carbonate and 1000g of tetrahydrofuran to a 2000ml four-necked round-bottomed flask equipped with mechanical stirring, a thermometer, and a reflux condenser. After stirring and mixing, add 288g of potassium fluoride solid and 4.5g of γ-ethane base-cyclodextrin. Heat up to 50°C in an oil bath. After 2.5 hours of heat preservation reaction, it was filtered. The solution was analyzed, and the content of fluoroethylene carbonate (FEC) measured by gas chromatography was 402.9g, and the conversion rate of FEC reached 93.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com