Styrene/maleic anhydride compound and preparation method thereof

A technology of maleic anhydride and styrene, applied in the field of polymers, can solve the problems of low pollution, high energy consumption, large solvent consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

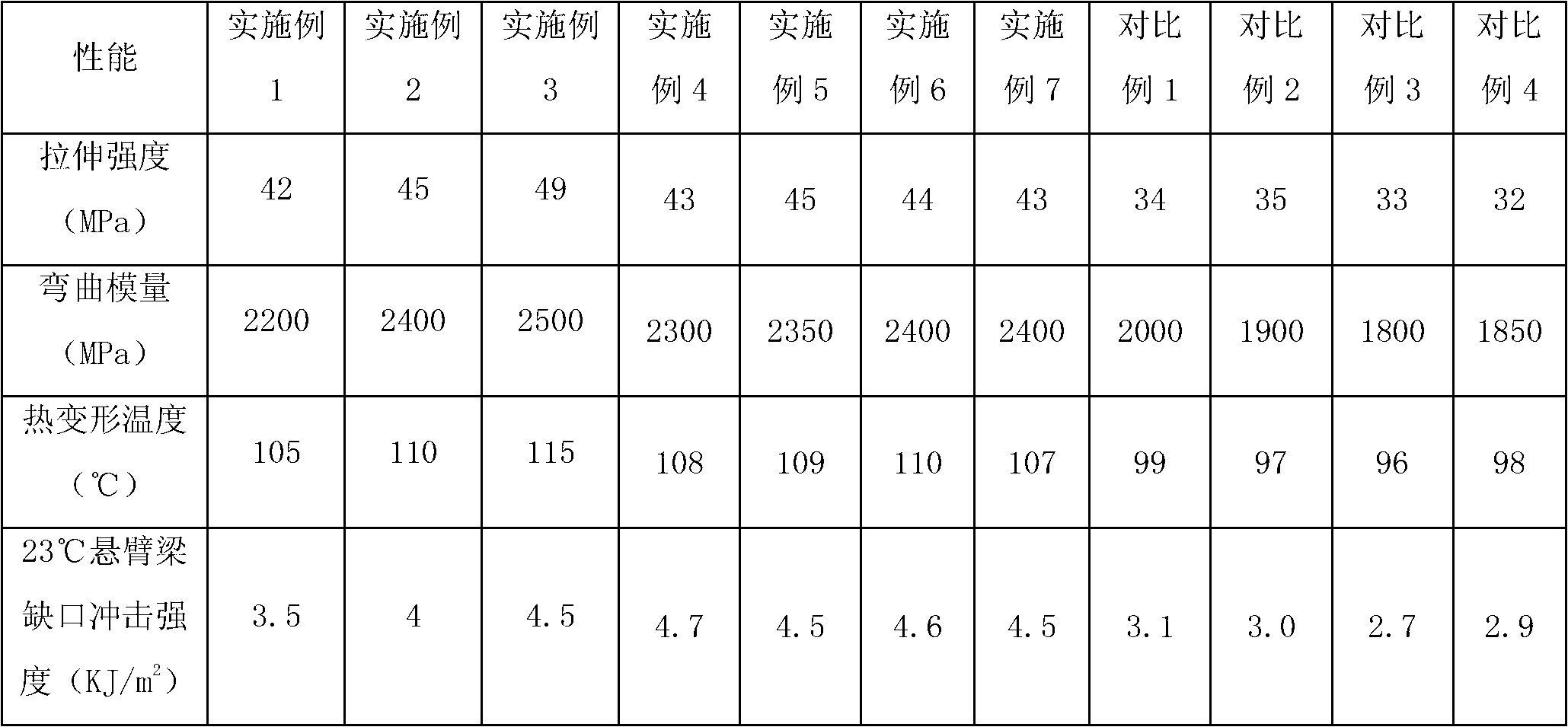

Examples

Embodiment 1

[0050] Dissolve 5 kg of maleic anhydride monomer, 0.1 kg of polarity regulator tetrahydrofuran (THF), and 0.1 kg of free radical initiator AIBN into 94.8 kg of styrene monomer, and inject through a high-pressure plunger metering pump with an aspect ratio of 64: 1. The whole process sealed reaction twin-screw extruder, the temperature of each section of the extruder barrel is: the temperature of the material section is 150°C, the temperature of the reaction section is 200°C, the temperature of the homogenization section is 200°C, and the temperature of the conveying section is 200°C.

[0051] The rotational speed of the screw is 100 rpm.

[0052] Under the high temperature inside the extruder and the shear dispersion of screw elements, random copolymerization of styrene and maleic anhydride occurs under the action of free radical initiators and polarity regulators, and the reaction completely forms SMA random copolymers , between the outlet of the homogenization section and the...

Embodiment 2

[0054] Dissolve 15 kg of maleic anhydride monomer, 0.5 kg of polar regulator tetramethylethylenediamine (TMEDA), and 0.5 kg of free radical initiator BPO into 84 kg of styrene monomer, and inject it into the long-term through a high-pressure plunger metering pump. The whole process sealed reaction twin-screw extruder with a diameter ratio of 64:1, the temperature of each section of the extruder barrel is: the temperature of the material section is 150°C, the temperature of the reaction section is 200°C, the temperature of the homogenization section is 200°C, and the temperature of the conveying section is 150°C. The section temperature is 200°C.

[0055] The rotational speed of the screw is 100 rpm.

[0056]Under the high temperature inside the extruder and the shear dispersion of screw elements, random copolymerization of styrene and maleic anhydride occurs under the action of free radical initiators and polarity regulators, and the reaction completely forms SMA random copoly...

Embodiment 3

[0058] Dissolve 25 kg of maleic anhydride monomer, 1 kg of polar regulator diethylene glycol dimethyl ether, and 1 kg of free radical initiator DCP into 73 kg of styrene monomer, and inject the aspect ratio through a high-pressure plunger metering pump. It is a 64:1 fully sealed reaction twin-screw extruder. The temperature of each section of the extruder barrel is: the temperature of the material section is 150°C, the temperature of the reaction section is 200°C, the temperature of the homogenization section is 200°C, and the temperature of the conveying section 200°C.

[0059] The rotational speed of the screw is 100 rpm.

[0060] Under the high temperature inside the extruder and the shear dispersion of screw elements, random copolymerization of styrene and maleic anhydride occurs under the action of free radical initiators and polarity regulators, and the reaction completely forms SMA random copolymers , between the outlet of the homogenization section and the inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com