Biodegradable heat-shrinkable material, biodegradable heat-shrinkable film and preparation method of biodegradable heat-shrinkable film

A biodegradable and heat-shrinkable technology, applied in the field of biodegradable heat-shrinkable film and its preparation, can solve the problem of high processing cost and achieve the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides a biodegradable heat-shrinkable material, the preparation process of which is as follows:

[0018] Take 500g PLA (number average molecular weight 45,000), 200g PBAT (number average molecular weight 35,000), 300g PCL (number average molecular weight 80,000) and 10g of ethylene isophthalate copolymer (number average molecular weight 8,000, melting point 110°C), After mixing, add the twin-screw extruder to melt and knead. The parameters of the melt kneading are as follows (twin-screw extruder; Φ=26mm; L / D=40; the temperature from the feeding zone to each zone of the die head is: 150 ℃, 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C; pressure 0.3~1.2MPa; torque 54%; feeding rate 23s), at around 230°C The blend is obtained, then extruded and granulated, and dried to obtain slices. The prepared slices were subjected to injection molding, the mold temperature was 110° C., and the cooling time was 120 seconds. The formed sheet was t...

Embodiment 2

[0020] This embodiment provides a biodegradable heat-shrinkable material, the preparation process of which is as follows:

[0021] Take 500g PLA (number average molecular weight 80000), 200g PBAT (number average molecular weight 60000), 300g PCL (number average molecular weight 60000) and 50g ethylene isophthalate copolymer (number average molecular weight 9000, melting point 120 ℃), mix Finally, it is added into a twin-screw extruder for melting and mixing. The parameters of melting and mixing are as follows (twin-screw extruder; Φ=26mm; L / D=40; the temperature from the feeding area to each area of the die head is: 150°C , 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C; pressure 0.3~1.2MPa; torque 54%; feeding rate 23s), prepared at about 230°C The blend is then subjected to extrusion granulation and dried to produce chips. The prepared slices were subjected to injection molding, the mold temperature was 110° C., and the cooling time was 120 seconds. Th...

Embodiment 3

[0023] This embodiment provides a biodegradable heat-shrinkable material, the preparation process of which is as follows:

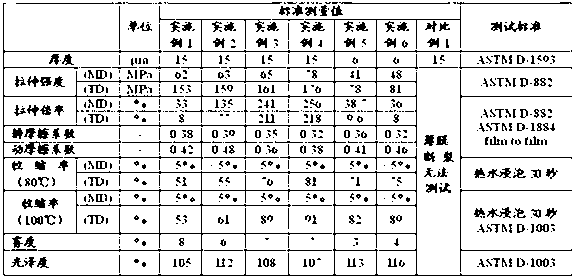

[0024] Take 500g PLA (number average molecular weight 110000), 200g PBAT (number average molecular weight 80000), 300g PCL (number average molecular weight 100000) and 100g ethylene isophthalate copolymer (number average molecular weight 9000 melting point 135 ℃), after mixing , into the twin-screw extruder for melting and mixing, the parameters of the melting and mixing are as follows (twin-screw extruder; 180°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C; pressure 0.3~1.2MPa; torque 54%; feeding rate 23s), a total of The mixture is then subjected to extrusion granulation and dried to obtain chips. The prepared slices were subjected to injection molding, the mold temperature was 110° C., and the cooling time was 120 seconds. The formed sheet was tested, and the test data is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com