Preparation method of micro/nano-structure ultrahigh-strength plastic stainless steel containing Nb

An ultra-high-strength, nano-structure technology, applied in the field of preparation of micro/nano composite structure ultra-high-strength plastic stainless steel, can solve the problems of poor mechanical stability, poor biocompatibility, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

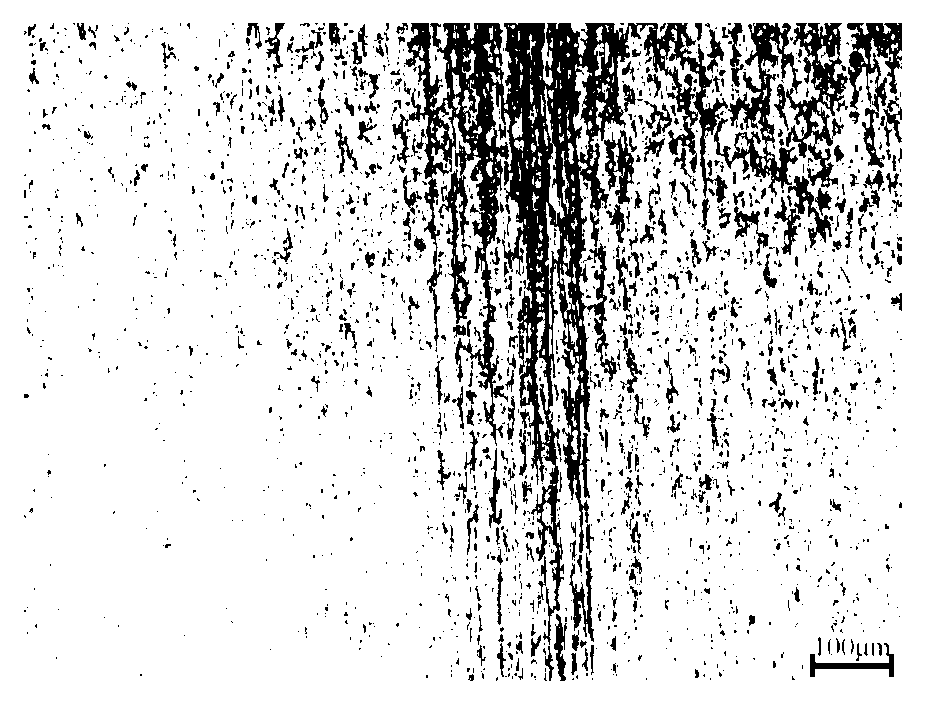

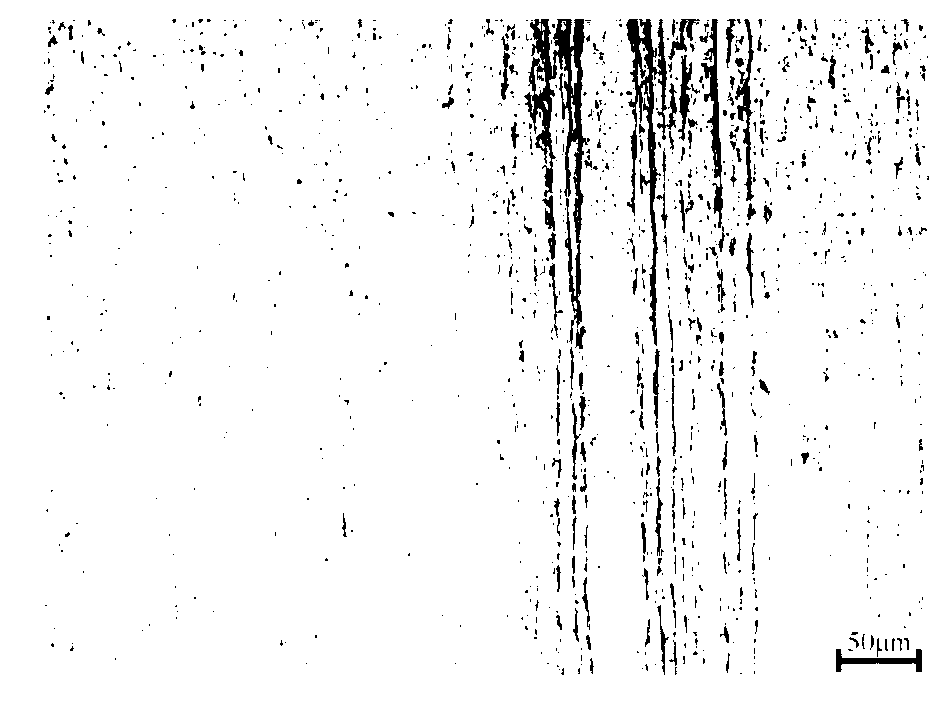

Image

Examples

Embodiment 1

[0030] The chemical composition is calculated by weight percentage, C0.017%; Si0.5%; Mn1.3%; Cr17.5%; Mo2.5%; Ni12%; N0.09%; Nb0.05%. According to the decarburization situation in the smelting process, graphite is properly added, and the sample steel ingot is obtained by smelting in a 50kg vacuum furnace according to the corresponding proportion. Cut the smelted billet, cut off the riser, and forge it into the required billet. The forging plan is: heat the billet to 1250°C, keep it warm for 2 hours and then forge it out of the furnace. The final forging temperature is not lower than 1100°C, forging to 20mm A steel ingot with thickness × 150mm width × 200mm length. Carry out soaking treatment on the blank, control the temperature of the blank to 1250°C, and keep it warm for 200 minutes, so that the microalloying elements in the steel can fully remelt. Descaling is carried out on the slab after it comes out of the furnace to remove the iron oxide scale produced during the heati...

Embodiment 2

[0034] The chemical composition is calculated by weight percentage, C0.017%; Si0.5%; Mn1.3%; Cr17.5%; Mo2.5%; Ni12%; N0.09%; Nb0.05%. According to the decarburization situation in the smelting process, graphite is properly added, and the sample steel ingot is obtained by smelting in a 50kg vacuum furnace according to the corresponding proportion. Cut the smelted billet, cut off the riser, and forge it into the required billet. The forging plan is: heat the billet to 1250°C, keep it warm for 2 hours and then forge it out of the furnace. The final forging temperature is not lower than 1100°C, forging to 20mm A steel ingot with thickness × 150mm width × 200mm length. Carry out soaking treatment on the blank, control the temperature of the blank to 1250°C, and keep it warm for 200 minutes, so that the microalloying elements in the steel can fully remelt. Descaling is carried out on the slab after it comes out of the furnace to remove the iron oxide scale produced during the heati...

Embodiment 3

[0037] The chemical composition is calculated by weight percentage, C0.017%; Si0.5%; Mn1.3%; Cr17.5%; Mo2.5%; Ni12%; N0.09%; Nb0.05%. According to the decarburization situation in the smelting process, graphite is properly added, and the sample steel ingot is obtained by smelting in a 50kg vacuum furnace according to the corresponding proportion. Cut the smelted billet, cut off the riser, and forge it into the required billet. The forging plan is: heat the billet to 1250°C, keep it warm for 2 hours and then forge it out of the furnace. The final forging temperature is not lower than 1100°C, forging to 20mm A steel ingot with thickness × 150mm width × 200mm length. Carry out soaking treatment on the blank, control the temperature of the blank to 1250°C, and keep it warm for 200 minutes, so that the microalloying elements in the steel can fully remelt. Descaling is carried out on the slab after it comes out of the furnace to remove the iron oxide scale produced during the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com