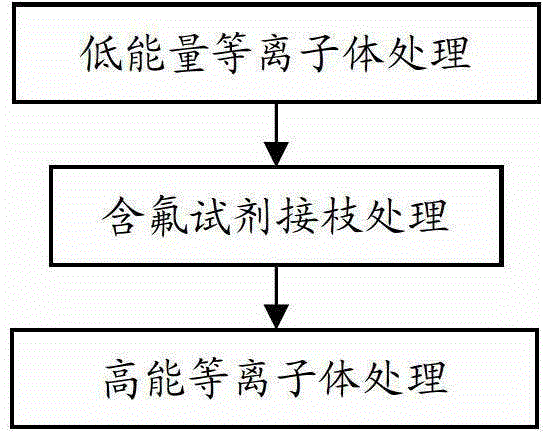

A method, production line and application of three-resistant finishing for non-woven fabrics

A technology of non-woven fabrics and production lines, applied in fiber processing, physical processing, textiles and papermaking, etc., can solve the problems of slow processing speed and high equipment requirements, and achieve the effect of increasing speed, improving processing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

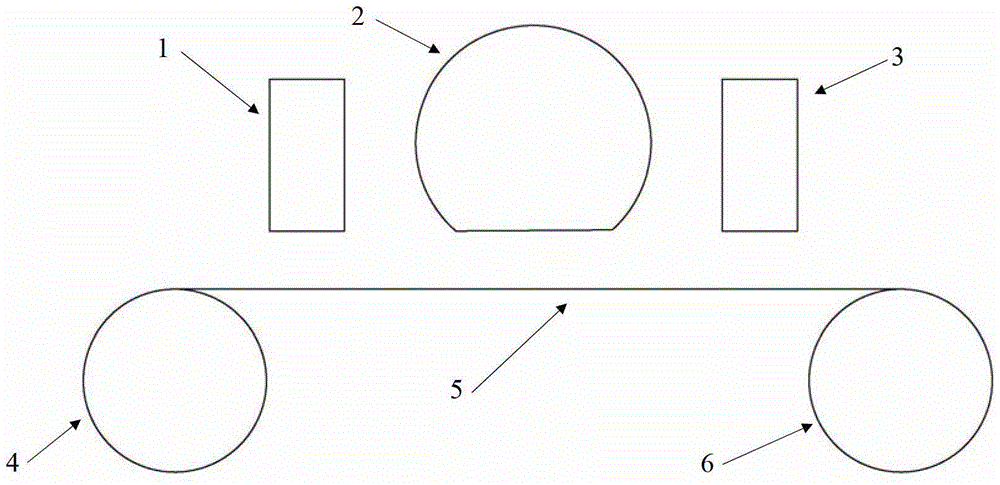

[0028] In this example, the non-woven three-anti-finishing production line, such as figure 2 As shown, it includes an unwinding device 4 , a low-energy plasma processing device 1 , a reagent evaporation device 2 , a high-energy plasma processing device 3 , and a winding device 6 , which are carried out sequentially. The nonwoven in this example is a 45gsm spunmelt nonwoven with a 36gsm spunbond layer and a 9gsm meltblown layer. In this example, the reagent evaporation equipment 2 is a vacuum evaporation equipment, which is used to evaporate the fluorine-containing reagent into a gaseous state. In this example, the used fluorine-containing reagent is 2-acrylic acid-pentafluoroethyl ester, and other optional fluorine-containing reagents are also Including 2-propenoic acid-2,2,3,3,4,4,5,5,6,6,7,7,8,8,8-pentadecafluorooctyl, 2-propenoic acid-2-methyl- 2,2,3,3,4,4,5,5,6,6,7,7,8,8,8-Pentadecafluorooctyl, 2-Acrylic acid-2-methyl-pentafluorophenyl, 2,3,4,5,6-Pentafluorostyrene, 2,2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com