Dyeing auxiliary WPN for attenuated wool and common wool mixed strips as well as dyeing method

A technique of drawing fine wool and dyeing auxiliaries, which is applied in the field of drawing wool-common wool mixed top dyeing auxiliary WPN, drawing wool-common wool mixed top for dyeing, and can solve problems such as top collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Wool dyeing auxiliaries WPN, composed of alkyl polyoxyethylene nonionic surfactants and aluminum salts in mass percentage, 50% of alkyl polyoxyethylene nonionic surfactants, 50% of aluminum salts, the above groups The sum of the contents is 100%.

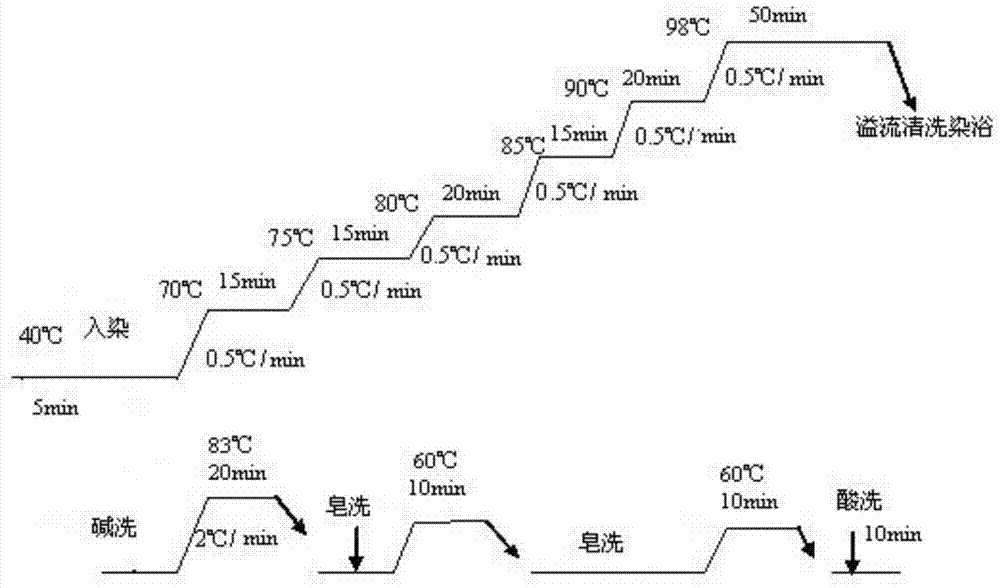

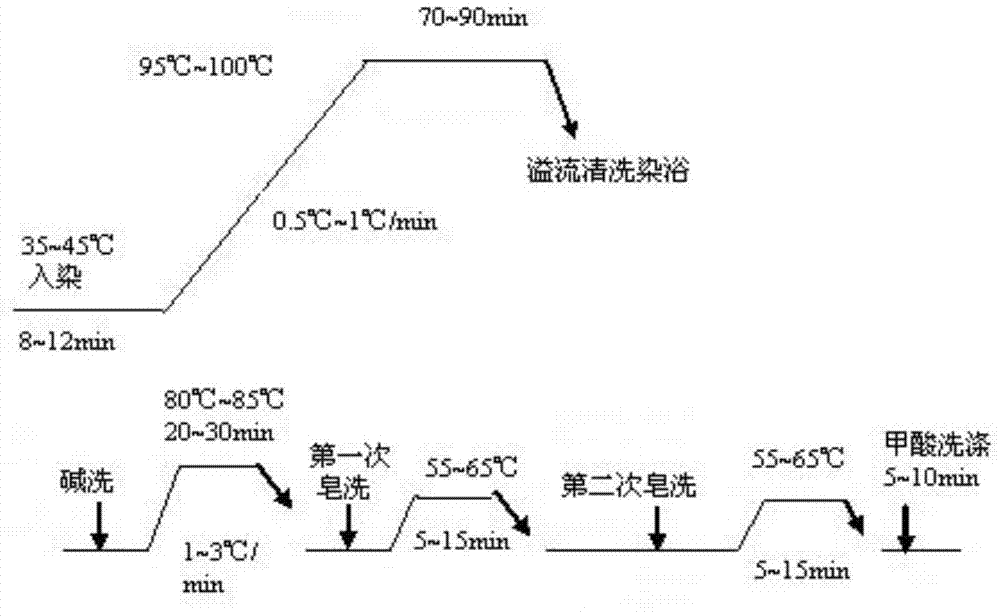

[0064] According to the mass ratio of 3:17, draw fine wool-ordinary wool mixed tops and ordinary wool tops with the same count on the drawing frame to form mixed wool tops; weigh Lanasol CE blue dye according to the quality of mixed wool tops, Lanasol CE The amount of blue dye is 0.7% owf. Dissolve the weighed dye in soft water at 45°C in the auxiliary tank to prepare a dye solution with a mass concentration of 2%. Use formic acid to adjust the pH of the dye solution to 4.5. Weigh the dyeing auxiliaries WPN, the amount of dyeing auxiliaries WPN is 1% owf, add the dyeing auxiliaries WPN to the prepared dye solution, then raise the temperature of the dye solution to 65 ° C, stir for 5 minutes, under stirring conditions Cool th...

Embodiment 2

[0066]WPN, a dyeing auxiliary for fine wool, is composed of a mixture of alkyl polyoxyethylene nonionic surfactants and aluminum salts in percentage by mass. The alkyl polyoxyethylene nonionic surfactants are 64.5%, and aluminum salts are 35.5%. The sum of the contents is 100%.

[0067] According to the mass ratio of 20:80, draw fine wool-ordinary wool mixed tops and ordinary wool tops with the same count on the drawing frame to form mixed wool tops; weigh Lanasol CE black dye and Lanasol CE black according to the quality of mixed wool tops. The amount of dyestuff is 2.6%owf. Dissolve the weighed dyestuff in soft water at 50°C in the auxiliary vat to prepare a dye solution with a mass concentration of 3%. Adjust the pH of the dye solution to 5 with formic acid. Weigh the dyeing auxiliary WPN, the amount of dyeing auxiliary WPN is 3% owf, add the dyeing auxiliary WPN to the prepared dye solution, then raise the temperature of the dye solution to 68 ° C, stir for 10 minutes, und...

Embodiment 3

[0069] WPN, a dyeing auxiliary for fine wool, consists of a mixture of alkyl polyoxyethylene nonionic surfactants and aluminum salts by mass percentage, with 76.2% of alkyl polyoxyethylene nonionic surfactants and 23.8% of aluminum salts. The sum of the contents is 100%.

[0070] According to the mass ratio of 70:99, draw fine wool-ordinary wool mixed tops and ordinary wool tops with the same count on the drawing frame to form mixed wool tops; weigh Lanasol CE navy blue dye and Lanasol CE navy blue according to the quality of the mixed wool tops The amount of dyestuff is 3.9%owf. Dissolve the weighed dyestuff in soft water at 55°C in the auxiliary vat to prepare a dye solution with a mass concentration of 4%. Use formic acid to adjust the pH of the dye solution to 5.5. Weigh the dyeing auxiliary WPN, the amount of dyeing auxiliary WPN is 4.5% owf, add the dyeing auxiliary WPN to the prepared dye solution, then raise the temperature of the dye solution to 70 ° C, stir for 15 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com