Large-deformation tunnel body supporting structure of soft rock tunnel in wrinkled area and construction method of large-deformation tunnel body supporting structure

A support structure and large deformation technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low yield, easy loose vaults, and collapse, and achieve high practicability, economical convenience, and strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

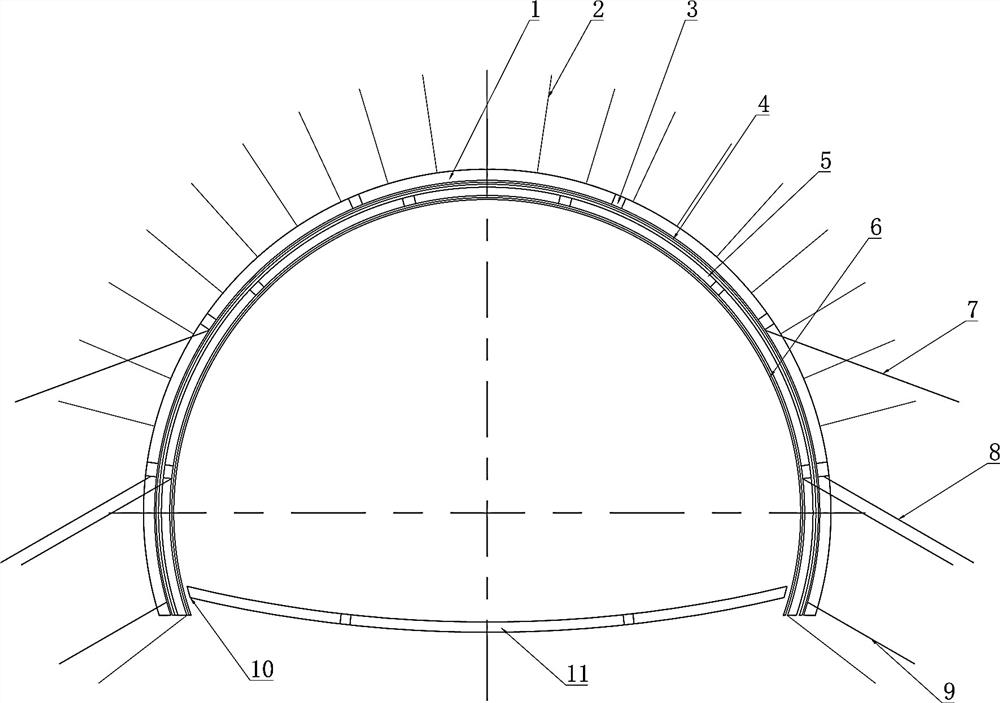

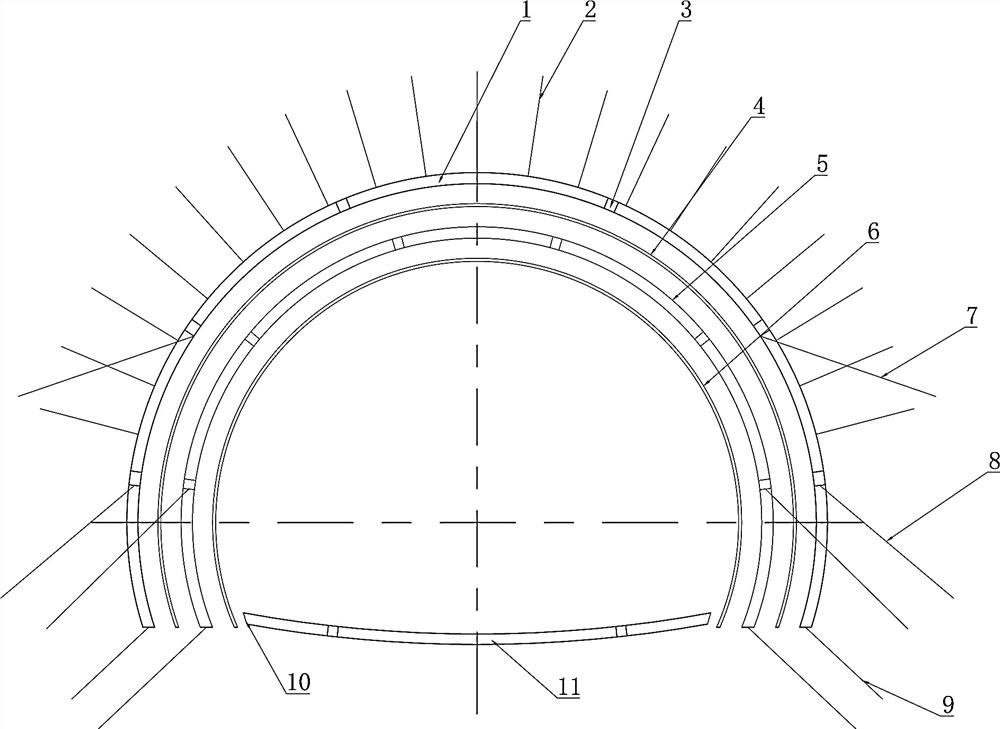

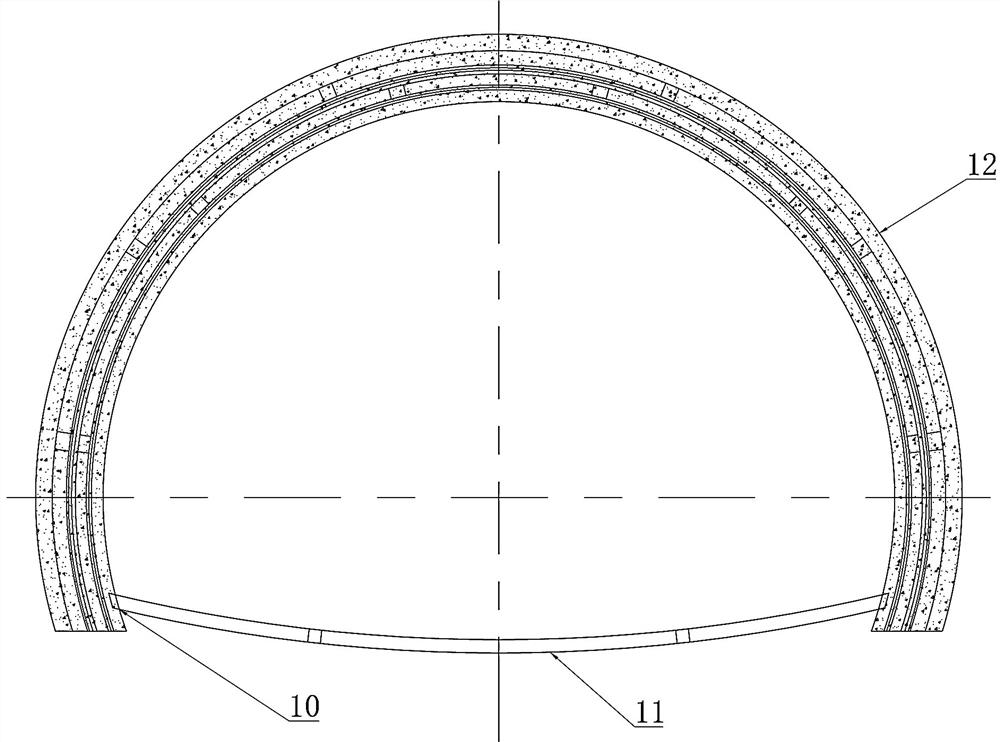

[0049] like Figure 1~17As shown in the figure, a large deformation tunnel body supporting structure of a soft rock tunnel in a folded area consists of a plurality of steel bodies to form a grid arch frame 1 of a ring structure, and a plurality of steel bodies are arranged inside the grid arch frame 1 to form a ring structure steel arch frame 5, between the steel arch 5 and the grille arch 1, an outer layer of steel mesh 4 is provided, the inner wall of the steel arch 5 is provided with an inner layer of steel mesh 6, and the bottom opening of the steel arch 5 is provided with a lower step arch 11, The lower step arch 11 and the steel arch 5 form a closed loop. The outer wall of the grille arch 1 is also provided with a plurality of vertically arranged steel flower tubes 2 . The outside of the steel arch 5 and the grid arch 1 are also provided with a plurality of locking foot anchor pipes inclined downward. The grid arch 1 , the lower step arch 11 and the steel arch 5 are al...

Embodiment 2

[0053] like Figures 8~13 As shown, in the preferred solution, the structure of the first arch connector 3 is as follows: the two sides of the second fixing plate 104 of the second steel body 102 are provided with positioning claws 301, and the positioning claws 301 pass through the second fixing plate 104 and The rotating shaft 302 is connected, the two sides of the first fixing plate 103 of the first steel body 101 are clamped on the positioning claws 301, and the first fixing plate 103 and the second fixing plate 104 are connected by a plurality of double-headed nuts. The grid arch 1 , the lower step arch 11 and the steel arch 5 are all assembled by connecting rigid bodies through the first arch connecting head 3 . The first arch connecting head 3 is mainly connected by a plurality of double-headed nuts through the first fixing plate 103 and the second fixing plate 104, and is simply positioned by the positioning claws 301, and then the grille arch 1, the lower step arch 11...

Embodiment 3

[0060] like Figures 14~17 As shown, in the preferred solution, the lower step arch 11 and the steel arch 5 are connected by a second arch connecting head 10 . The structure of the second arch frame connector 10 is as follows: a third fixing plate 501 is provided on one side of the steel arch 5 , limiting claws 1001 are arranged on both sides of the third fixing plate 501 , and the limiting claws 1001 pass through the third fixing plate 501, and a limit plate 1002 is provided at the end of the limit claw 1001, the fourth fixed plate 1101 at the end of the lower step arch 11 is clamped on the limit claw 1001, and the fourth fixed plate 1101 and the third fixed plate 501 pass through A plurality of studs are connected; the second arch connector 10 can connect the steel arch 5 and the lower step arch 11, and the angle between the lower step arch 11 and the steel arch 5 can pass through the second arch connector 10 to adjust, the limiting claw 1001 is used to limit the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com