Abrasion-resistant sleeve of drilling machine

A technology of anti-wear sleeves and drilling rigs, which is applied in the direction of drill pipes, drill pipes, casings, etc., and can solve the problems of casing wear, tear, complicated maintenance procedures, water leakage and oil leakage, etc., and achieve easy processing, manufacturing, assembly, and return Good elasticity and manufacturability, large contact stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

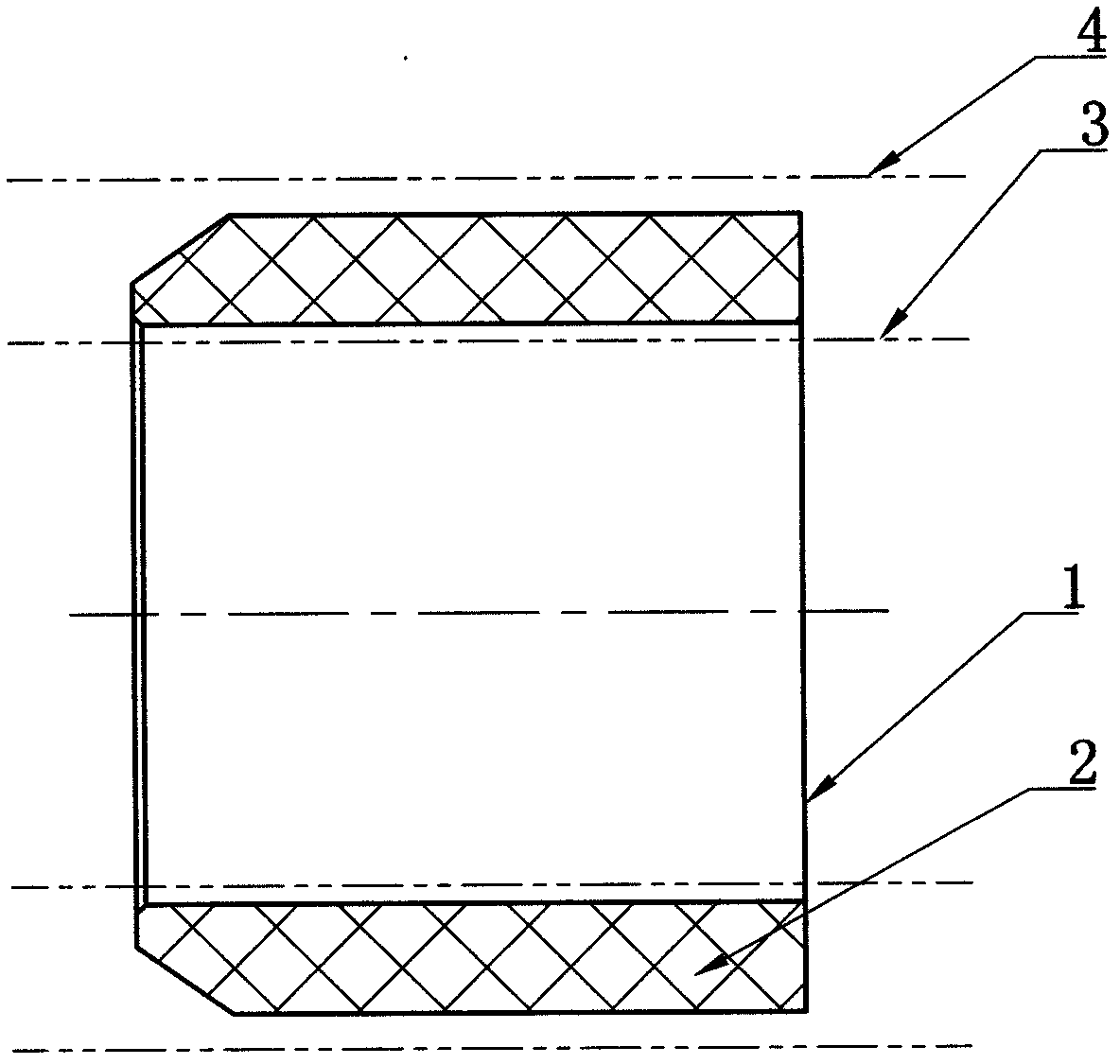

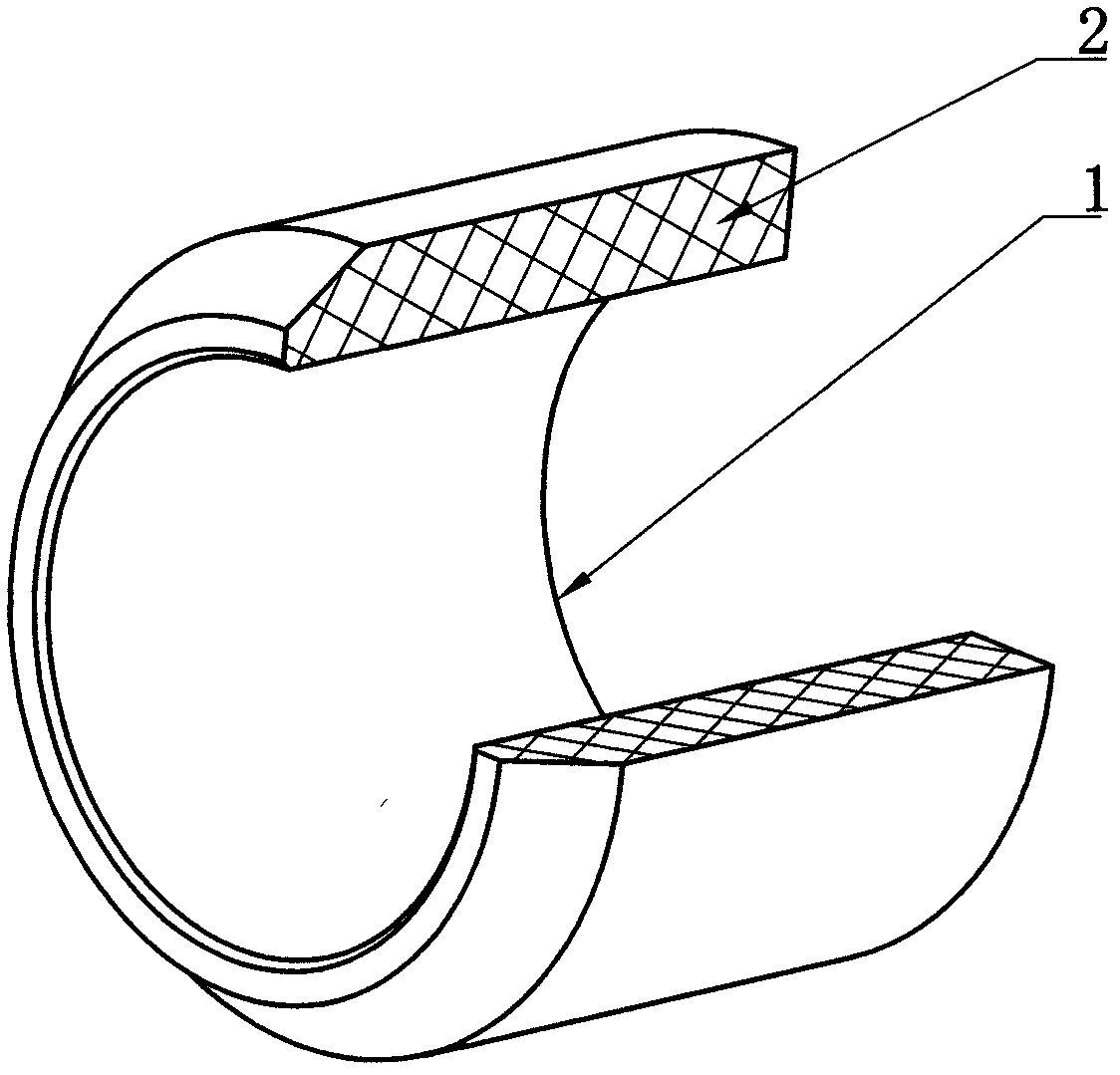

[0008] see Figure 1 ~ Figure 2 , The anti-wear sleeve of the drilling rig of the present invention includes an anti-wear sleeve 1, and the anti-wear sleeve 1 is composed of a plastic body 2. The plastic body 2 is a wear-resistant plastic body with large contact stress, good compressibility, resilience and manufacturability, which not only protects the wear-resistant sleeve 1 itself from being damaged, but also protects the drill pipe 3 located in the inner hole of the wear-resistant sleeve from being damaged. The casing 4 that is worn and located outside the wear sleeve is not worn and broken. The anti-wear sleeve 1 is a circular tubular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com