Premixed combustion system of diesel engine

A pre-mixed combustion and diesel engine technology, applied in the direction of charging system, combustion engine, mechanical equipment, etc., to achieve the effect of simple exhaust gas after-treatment system, maintaining efficiency, and compensating for the loss of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

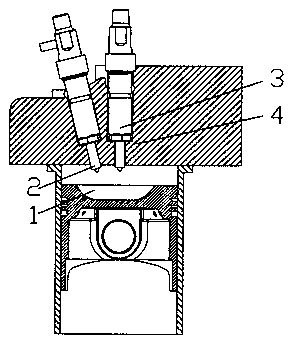

[0026] figure 1 The shown diesel engine premixed combustion system main fuel injector and secondary fuel injector both adopt the way of in-cylinder direct injection.

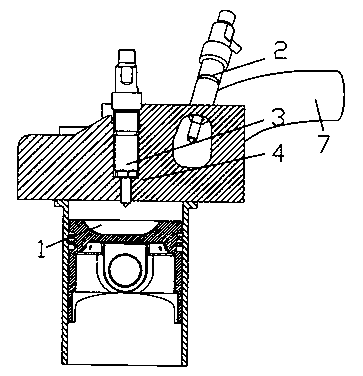

[0027] figure 2 The sub-injector of the pre-mixed combustion system shown in the diesel engine adopts the method of in-cylinder direct injection, and the main injector is installed in the intake port.

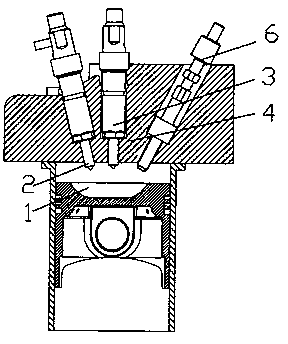

[0028] image 3 The main fuel injector, auxiliary fuel injector and water injector of the premixed combustion system of the diesel engine shown above all adopt the method of in-cylinder direct injection.

[0029] Figure 4 The main fuel injector and auxiliary fuel injector of the diesel premixed combustion system shown in the figure adopt the method of direct injection in the cylinder, and the water injector is installed in the intake passage.

[0030] Figure 5 The diesel engine pre-mixing combustion system shown makes the main injector and the auxiliary injector into an integrated injector, and adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com