Online monitoring device for structural damage of high temperature pressure pipeline

A technology for pressure pipelines and monitoring devices, applied in pipeline systems, using stable tension/pressure to test the strength of materials, mechanical equipment, etc. Larger and other problems, to achieve the effect of light weight, small system error, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

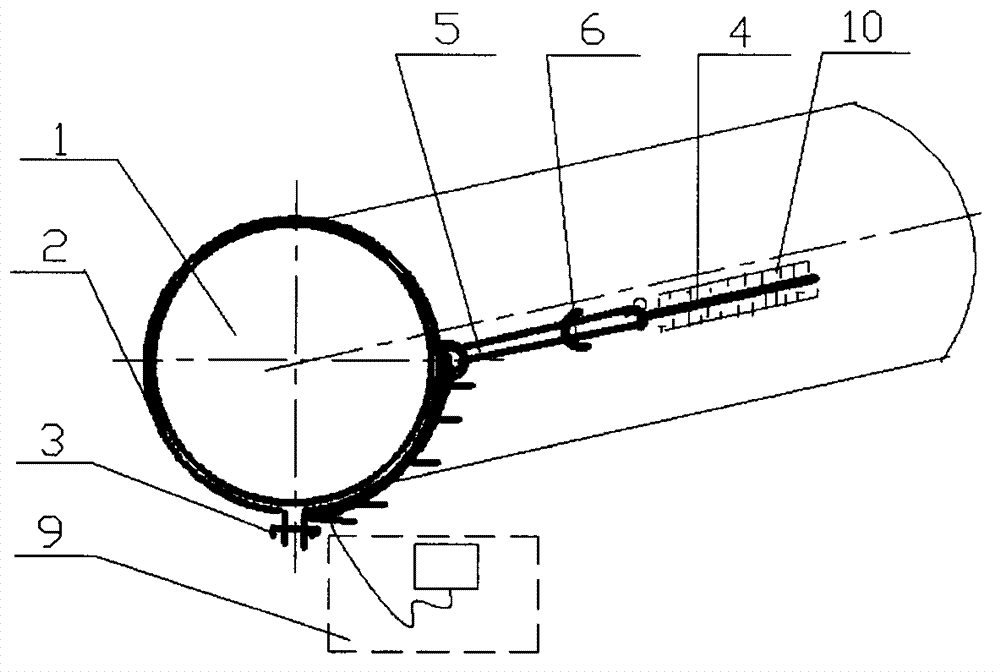

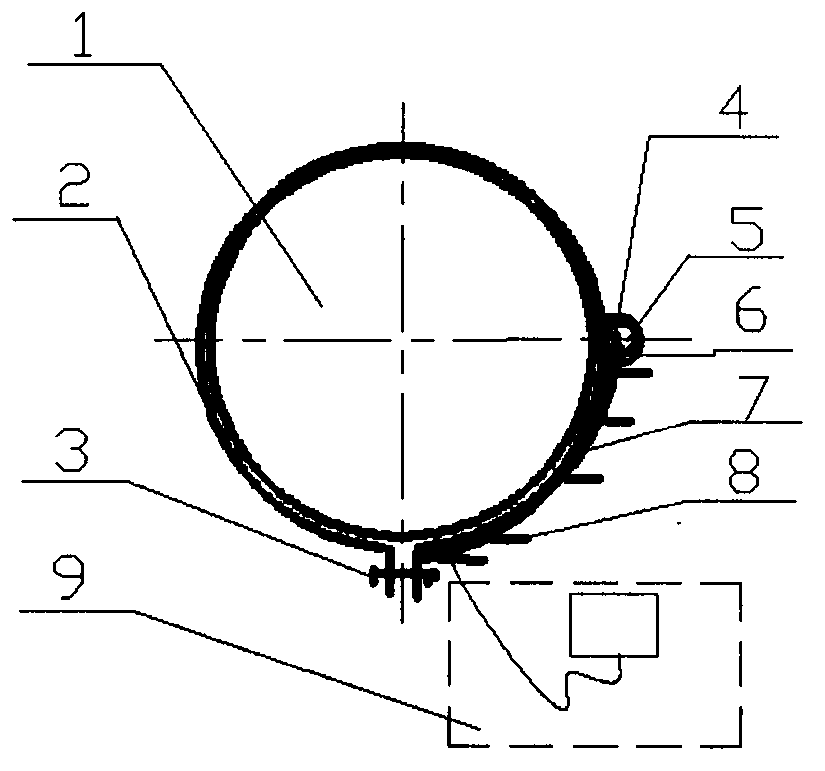

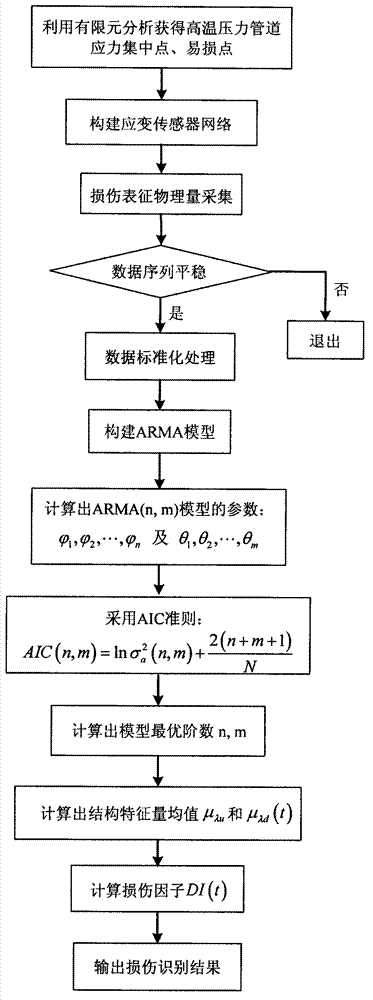

[0019] A certain example of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0020] The method proposed by the present invention is used for damage identification of in-service high-temperature pressure pipelines in a thermal power plant. A thermal power unit with basic load that has been in operation for more than 10 years in a certain plant has a superheated steam pressure of 26MPa and a temperature of 600°C. The material of the main steam pipeline is 12Cr1MoV steel with a specification of Φ540×85mm. Real-time monitoring of 20 vulnerable key points of the main steam pipeline is aimed at dynamically monitoring the structural safety stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com