Coal dust fine combustion heating and cooling combined system

A technology of cooling and heating combined supply and pulverized coal, which is applied in the fields of environmental protection and pulverized coal combustion, can solve the problems of application limitations and high fuel prices, and achieve the effects of saving manpower, energy saving and emission reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

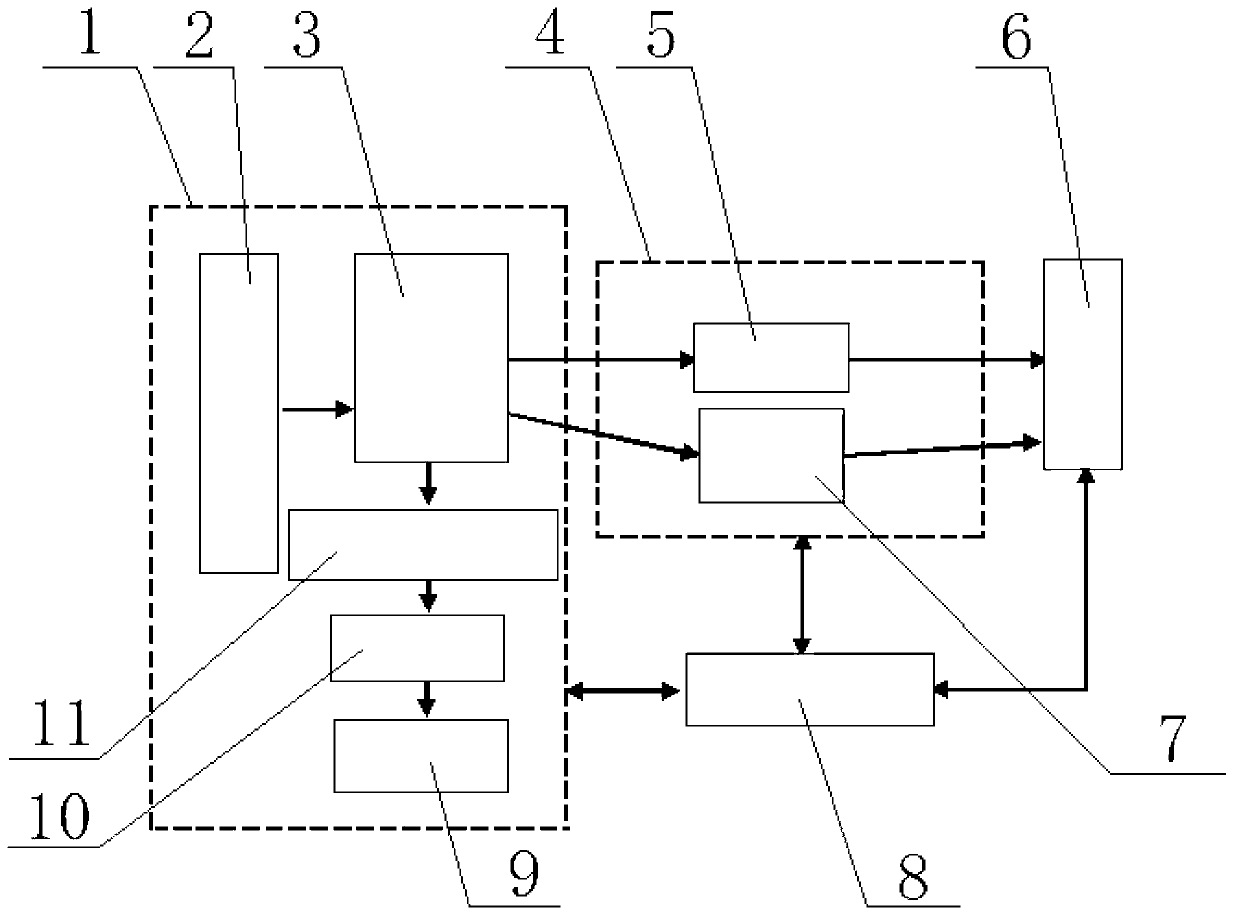

[0013] like figure 1 As shown, the pulverized coal fine combustion combined cooling and heating system includes a steam generating device 1, an intelligent control system 8 and a user 6, wherein the user includes a heating pipe network and a cold air pipe network, and its characteristic is that it also includes an exchange and refrigeration link 4; The exchange and refrigeration link includes a heat exchange device 5 and a refrigerator 7, wherein the hot water outlet of the heat exchange device is connected to the heating pipe network through a pipeline, and the cold air outlet of the refrigerator is connected to the cold air pipe network through a pipeline; the steam The generating device includes pulverized coal fine processing device 2, pulverized coal low-nitrogen combustion and sulfur fixation device 3, dust removal device 11, desulfurization tower 10 and chimney 9, wherein pulverized coal fine processing device 2 is connected with pulverized coal low-nitrogen combustion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com