Energy-saving blast furnace system for self-supplying oxygen-enriched air by using waste heat and pressure

A technology of oxygen-enriched air and residual pressure, applied in blast furnaces, blast furnace details, process efficiency improvement, etc., can solve problems such as underutilization, reduce energy form conversion, improve recycling efficiency, and increase recycling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

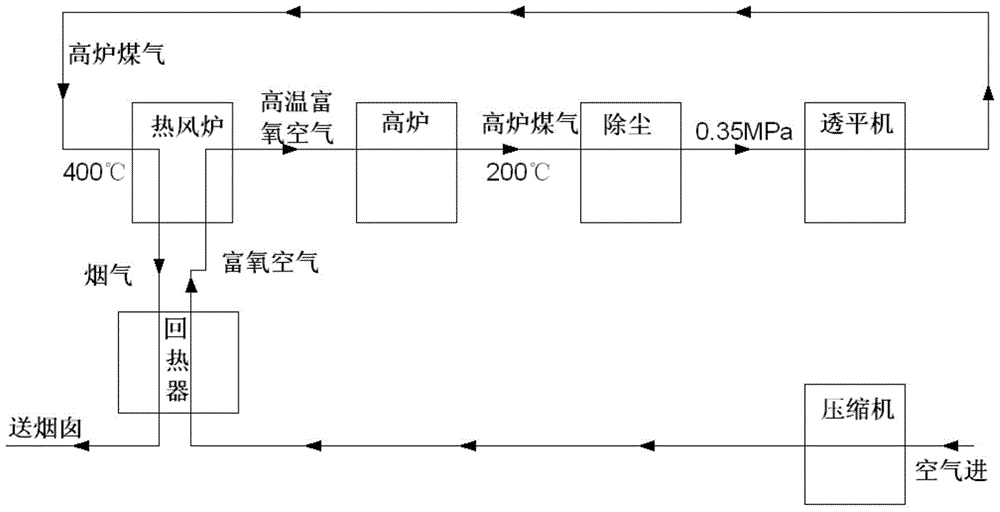

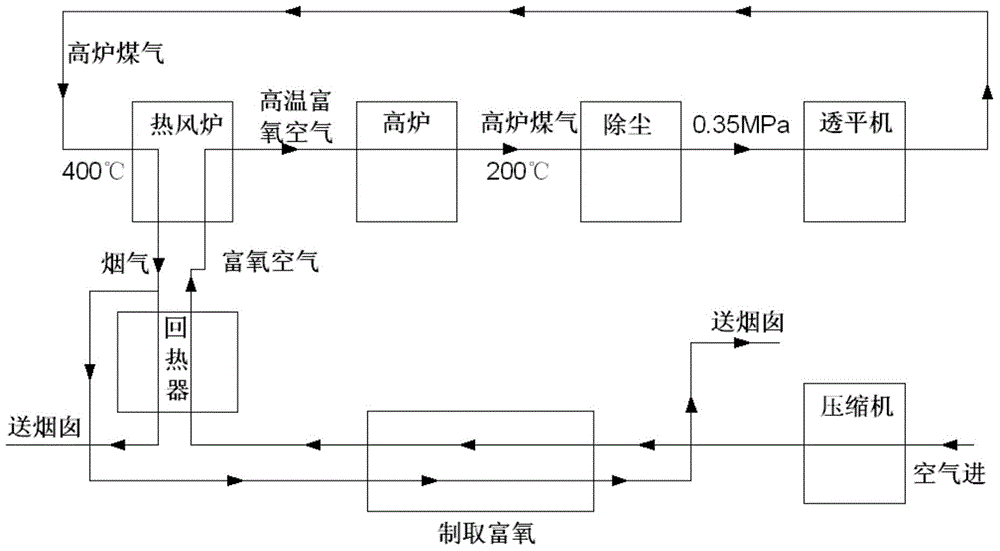

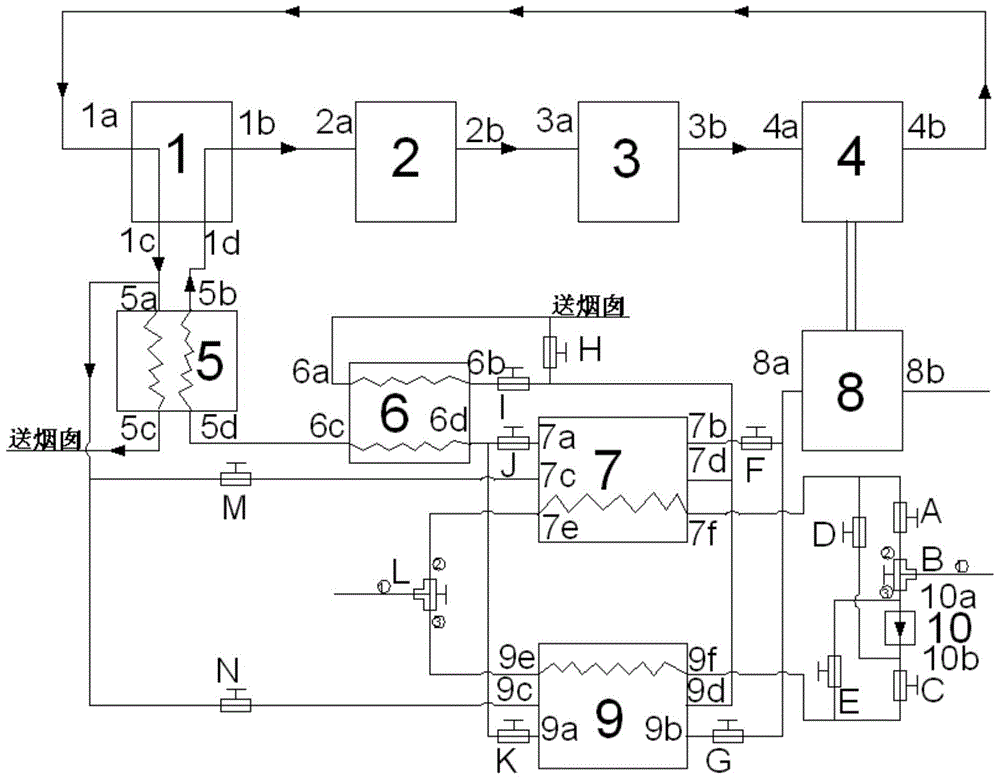

[0042] Such as figure 2 As shown, an energy-saving blast furnace system based on variable temperature variable pressure coupled adsorption that utilizes waste heat and pressure to self-supply oxygen-enriched air consists of a traditional ironmaking subsystem and an oxygen-enriched production subsystem.

[0043] The traditional ironmaking subsystem consists of a hot blast stove 1, a blast furnace 2, a dust removal device 3, a turbine 4, and a first heat exchanger 5 at the entrance of the hot blast stove;

[0044] The oxygen enrichment production subsystem consists of the second heat exchanger 6 after the adsorption tower, the first absorption / desorption tower 7 , the compressor 8 , the second absorption / desorption tower 9 and the heat exchange medium pump 10 .

[0045] The connections of the above components are as follows:

[0046] The oxygen-enriched air outlet 1b of the hot blast stove 1 is connected to the oxygen-enriched air inlet 2a of the blast furnace 2; the blast fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com