Gas-liquid heat exchange type refrigeration device

A gas-liquid heat exchanger and refrigeration device technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as changes in heat exchange performance of gas-liquid heat exchangers, deterioration of refrigerator oil, and rise in refrigerant discharge temperature. Achieve the effects of suppressing poor cooling, preventing freezing, and suppressing the rise in discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

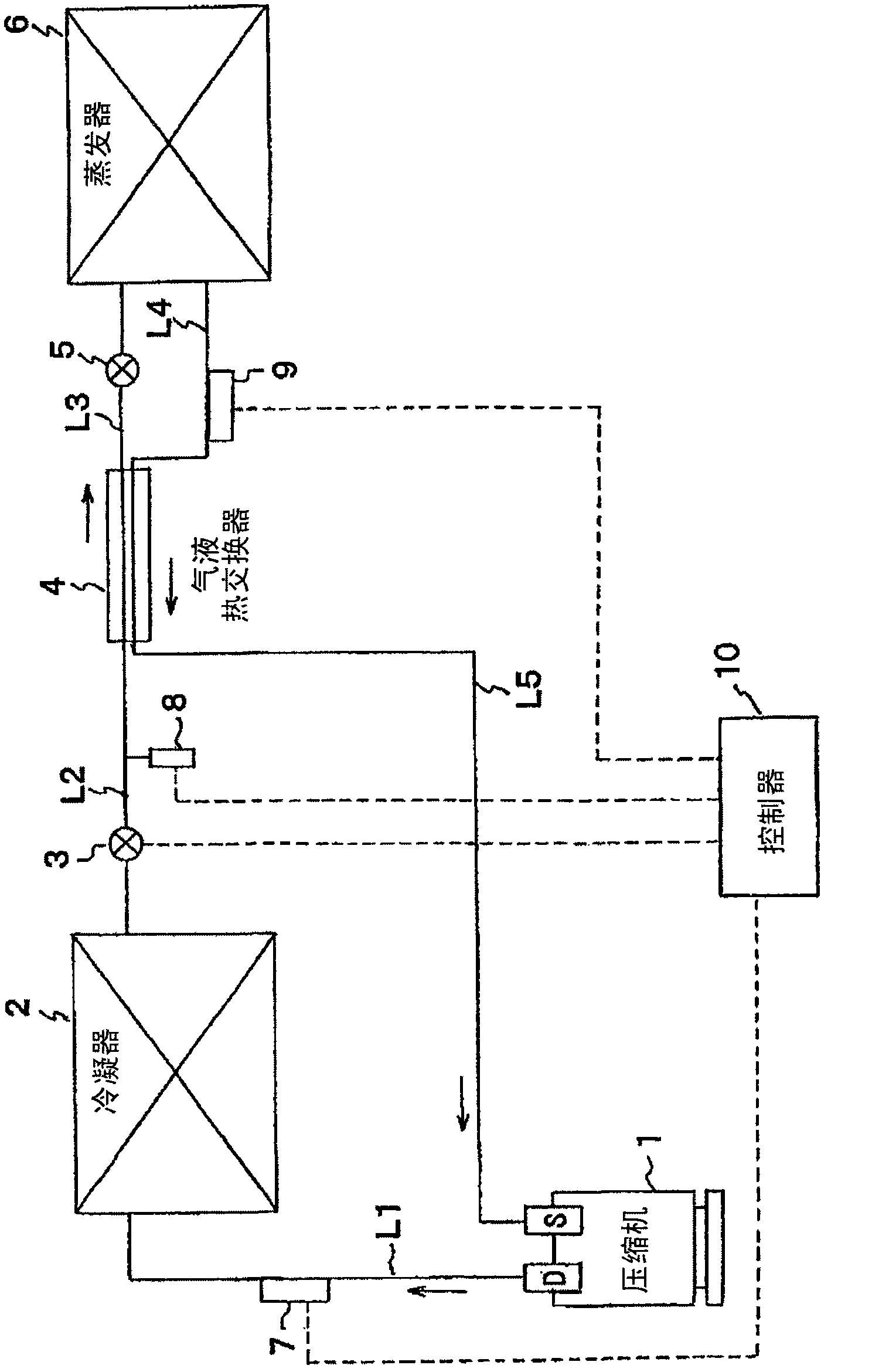

[0036] figure 1 It is a refrigerant circuit diagram of the gas-liquid heat exchange type refrigeration device of the present invention. In the gas-liquid heat exchange type refrigeration device shown in the figure, a compressor 1, a condenser 2, a heat exchange control valve 3, a gas-liquid heat exchanger 4, The expansion valve 5 and the evaporator 6 are connected in series by refrigerant lines L1 , L2 , L3 , L4 , and L5 to form a closed refrigerant circulation circuit. Here, the heat exchange control valve 3 is arranged on the refrigerant pipeline L2, and the refrigerant pipeline L2 is used to connect the condenser 2 and the gas-liquid heat exchanger 4; the expansion valve 5 is arranged on the refrigerant pipeline L3 , the refrigerant pipeline L3 is used to connect the gas-liquid heat exchanger 4 and the evaporator 6 . In addition, the heat exchange control valve 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com