Method for analyzing total phosphorus in industrial sewage sample

A technology for industrial sewage and samples, applied in the field of analyzing samples, can solve the problems of complicated operation, not simple enough operation, cumbersome operation process, etc., and achieve the effect of simple operation process, lower inspection cost, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The first step is to dilute the sewage sample to an appropriate concentration, pipette 8ml of the diluted sample,

[0019] In the second step, add 1ml of potassium persulfate solution, shake well, cover and heat at 120°C under normal pressure for 30 minutes, take out the water and cool to room temperature,

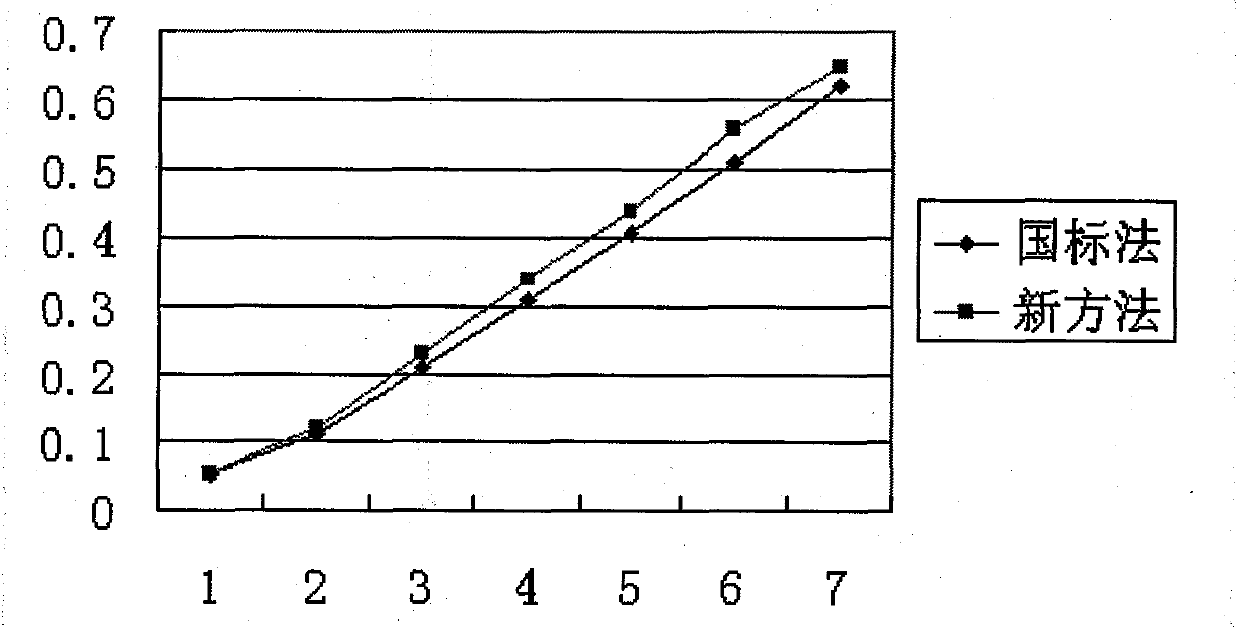

[0020] The third step is to add 0.3ml of 10% ascorbic acid solution, then add 0.3ml of molybdate solution, shake well, let it stand for 15 minutes, pour it into a cuvette, and use water as a reference at a wavelength of 710nm to measure Absorbance;

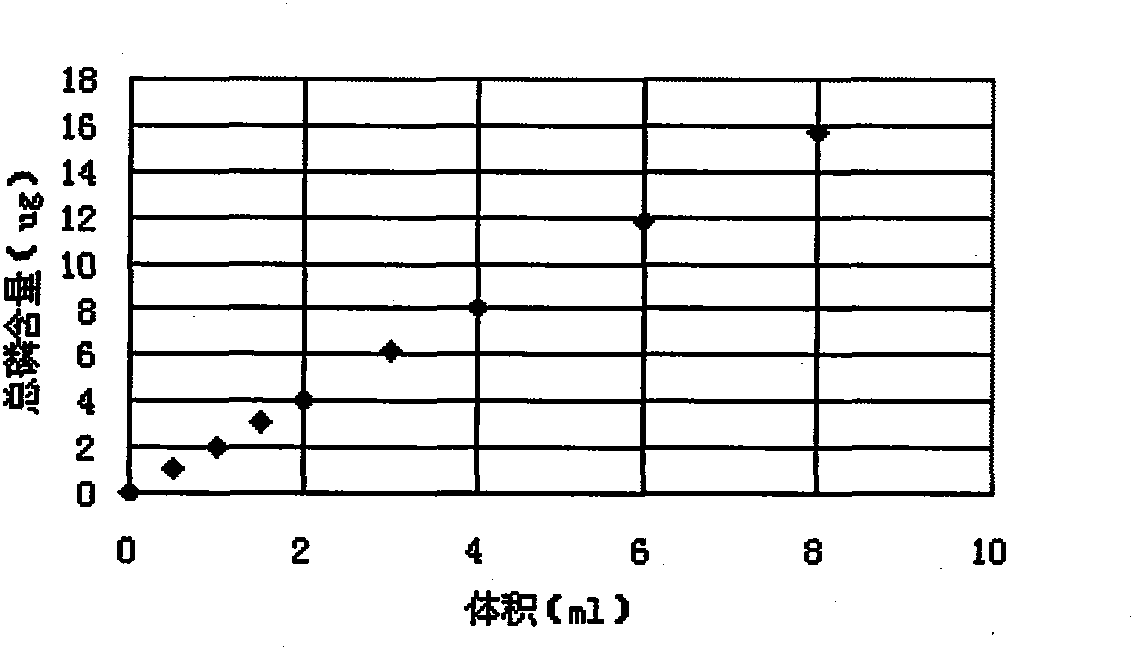

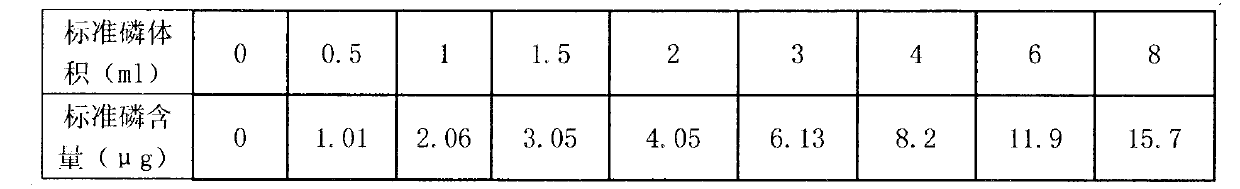

[0021] After deducting the absorbance of the blank test, check the phosphorus content from the working curve, phosphate content = phosphorus content found on the working curve / water sample volume, and the units of phosphorus content and water sample volume are μg / mL and mL respectively.

[0022] For the potassium persulfate solution described in the second step, 5 g of potassium persulfate was dissolved in dry water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com