Atomic force microscope system with quartz tuning fork

A technology of atomic force microscope and quartz tuning fork, which is applied in scanning probe microscopy, measuring devices, instruments, etc., to reduce the influence of background current, improve resolution, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred implementation example.

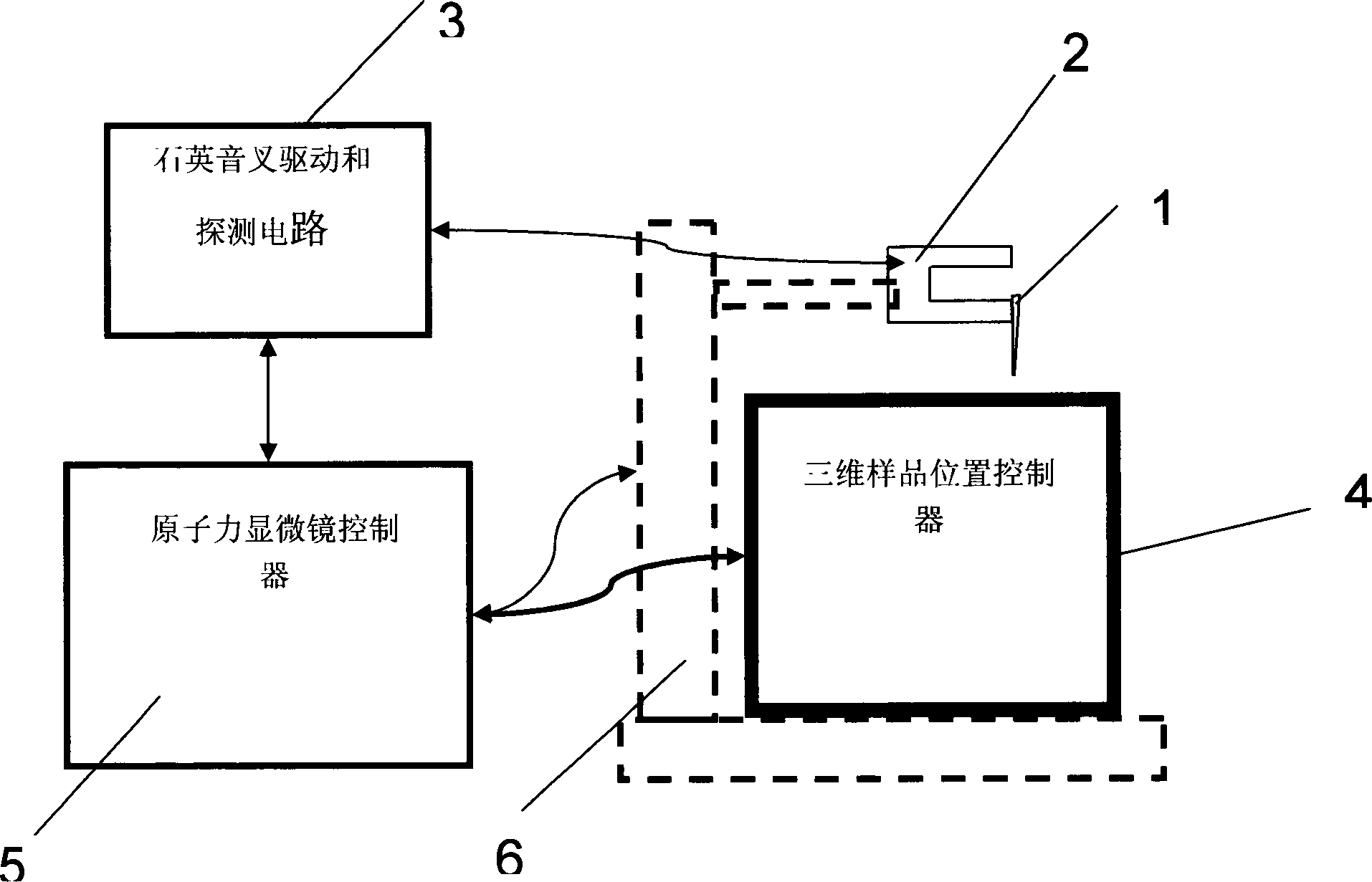

[0020] refer to figure 1 , the quartz tuning fork atomic force microscope system includes an atomic force probe, a quartz tuning fork detector, a quartz tuning fork drive and detection circuit, a three-dimensional sample position controller, an atomic force microscope controller, and other equipment for the atomic force microscope.

[0021] The tip of the atomic force microscope can be made of carbon nanotubes, or it can be made of gold or tungsten wire through chemical etching, and the length is about 2 mm.

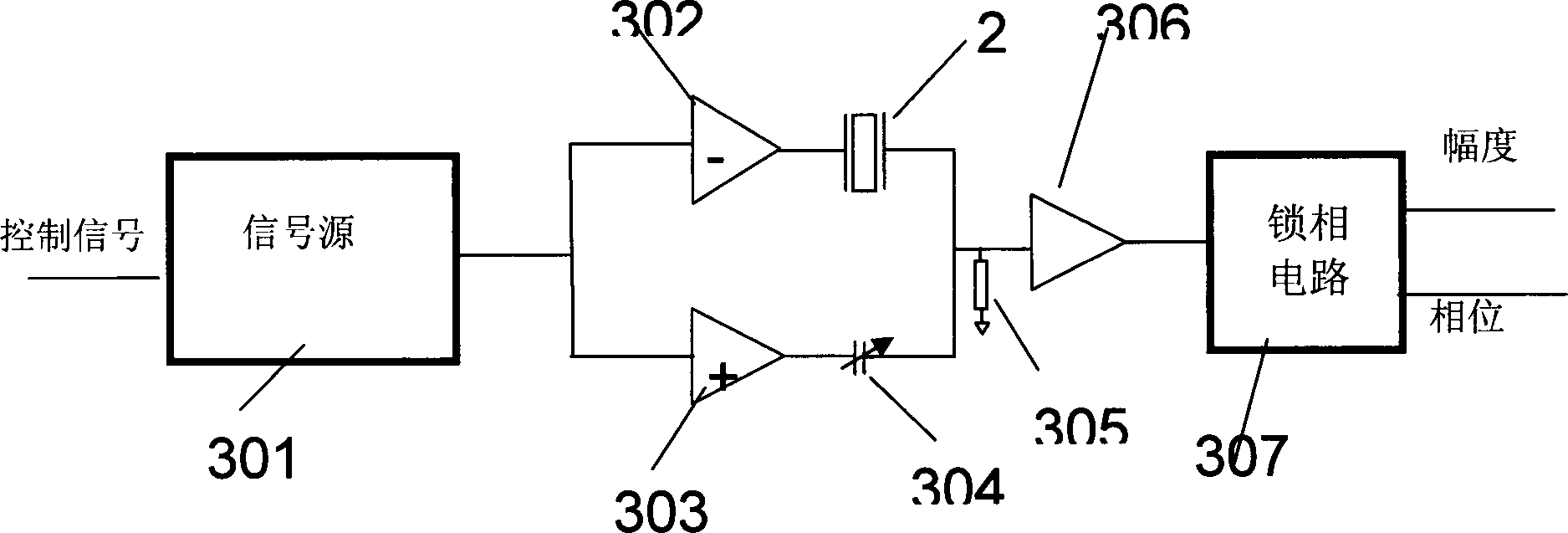

[0022] The quartz detector uses a quartz tuning fork with a resonant frequency of 32.768 kHz in the electronics. When assembling, spread the glue on the glass sheet to form a thin film, and then wipe the head of the quartz tuning fork on the glass sheet, so that the glue is glued on the head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com