Method for optimizing CDSEM (Critical Dimension Electronic Microscope) running sequence

A sequential, out-of-stock technology, applied in the direction of semiconductor/solid-state device testing/measurement, can solve the problems of high cost, low utilization rate of CDSEM, and high cost of CDSEM system, so as to reduce waiting time, improve production efficiency, and increase utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

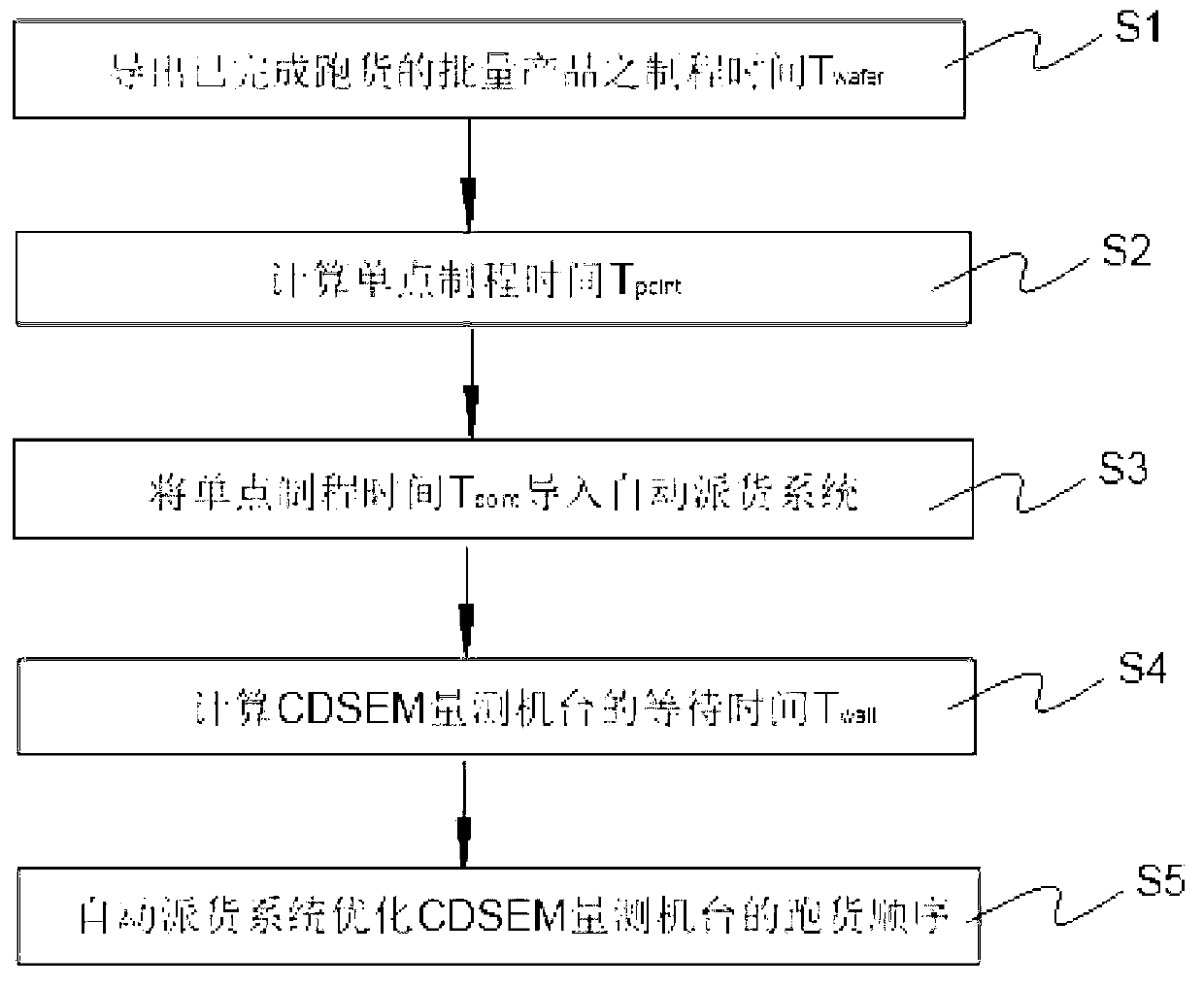

[0020] see figure 1 , figure 1 Shown is a flow chart of a method for optimizing CDSEM running order of the present invention. The method for described optimization CDSEM running order, comprises the following steps:

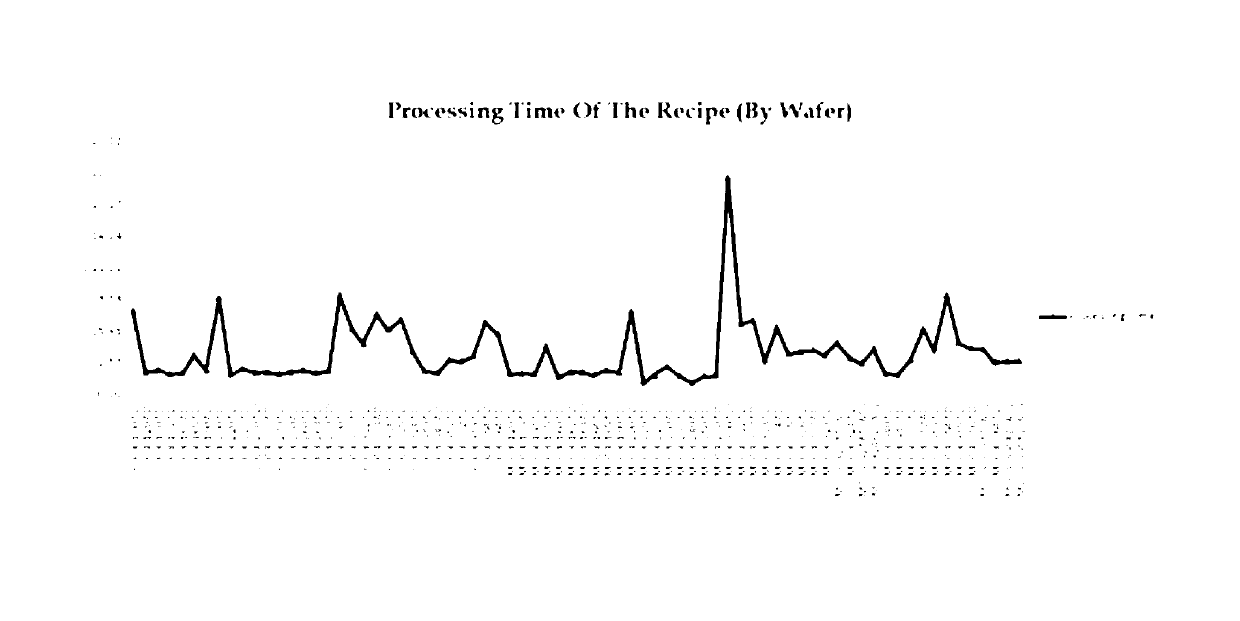

[0021] Execute Step S1: Use CDSEM to measure the prescription browser software to export the process time T of the batch products that have been shipped wafer ;

[0022] Execute step S2: Calculate the single-point process time T point ; Specifically, through the setting of the measurement program, combined with the CDSEM measurement prescription browser software, the process time T of the batch products that have completed the running goods is exported wafer , and according to the formula Calculate the single point p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com