Inductive coupling plasma processor and plasma substrate processing method

An inductively coupled plasma technology, applied in the direction of plasma, circuit, discharge tube, etc., can solve problems such as temperature rise, uneven plasma density, energy loss, etc., to increase reliability and stability, and reduce RF Effect of electromagnetic leakage and reduction of electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

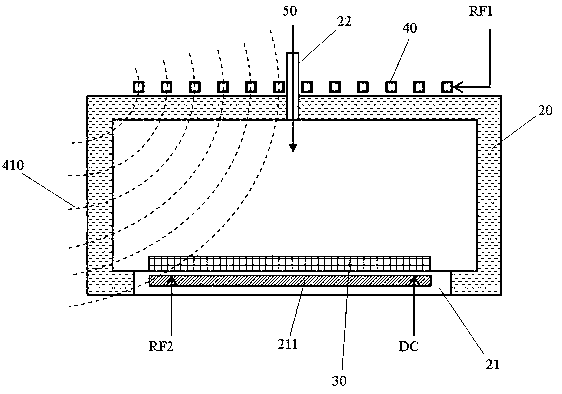

[0065] Cooperate see figure 2 , image 3 , Figure 4 As shown, the inductively coupled plasma processing device (ICP) in the present invention includes a vacuum reaction chamber 20 into which a reaction gas 50 is introduced. The top of the reaction chamber 20 is provided with an induction coil 40, which is connected with the first radio frequency source RF1 to generate an induction magnetic field, and induces a radio frequency electric field in the axial direction of the coil, thereby generating the said coil in the reaction chamber 20. Plasma of reactive gas 50 . The bottom of the reaction chamber 20 is provided with an electrostatic chuck 21 (ESC) and a base for fixing the substrate 30 .

[0066] As an improvement to the inductively coupled plasma processing device (ICP), the present invention also includes a magnetic field line adjustment component 10, which is made of a magnetically permeable material whose magnetic permeability is 10 times or more than that of air; du...

Embodiment 2

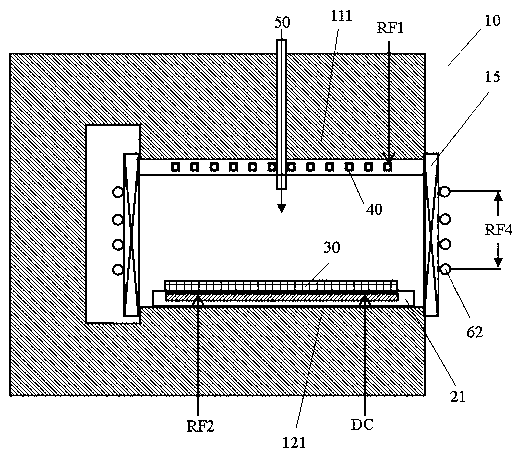

[0074] Cooperate see Figure 5 , 6 , 9, the overall structure of the inductively coupled plasma processing device (ICP) described in this example is similar to that in Example 1, including transformer-type, quasi-closed or barrel-type magnetic lines of force arranged around the reaction chamber 20 The adjustment part 10 is made of low reluctance magnetic materials such as ferrite; the induction coil 40 arranged on the outside of the top of the reaction chamber 20 is connected to most of the magnetic field lines of the induced magnetic field generated after the first radio frequency source RF1 flows through The magnetic flux adjusting component 10 and the structure of the magnetic flux adjusting component 10 determine the distribution of the magnetic flux inside and outside the reaction chamber 20 . Preferably, the magnetic field lines above the substrate 30 in the reaction chamber 20 are uniformly and linearly distributed to improve the uniformity of the plasma distribution o...

Embodiment 3

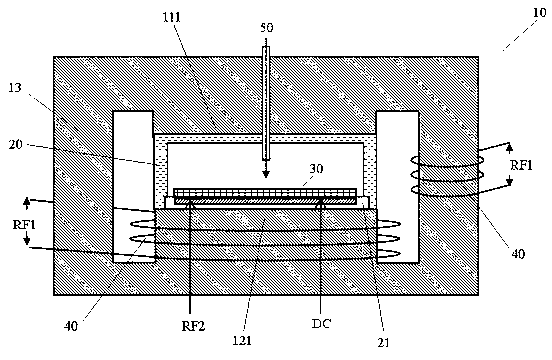

[0079] Cooperate to participate Figure 7 , 8 , 10, the overall structure of the inductively coupled plasma processing device (ICP) described in this example is similar to that in Embodiments 1 and 2, including transformer-type, quasi-closed-type or barrel-type surrounding the reaction chamber 20 The magnetic field line adjustment part 10, which is made of low reluctance magnetic material such as ferrite; the induction coil 40 arranged outside the top of the reaction chamber 20, most of the magnetic field lines of the induced magnetic field generated after connecting the first radio frequency source RF1 The magnetic force lines flow through the adjustment component 10 , and the distribution of the magnetic force lines inside and outside the reaction chamber 20 is determined by the structure of the magnetic force line adjustment component 10 . Preferably, the magnetic field lines above the substrate 30 in the reaction chamber 20 are uniformly and linearly distributed to improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com