Hole plugging device of base material and application thereof

A technology for plugging holes and substrates, which is applied to the formation of electrical connection of printing elements, etc., can solve the problems of the need for cleaning, the material cannot be recycled, and the effect is not ideal, so as to achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

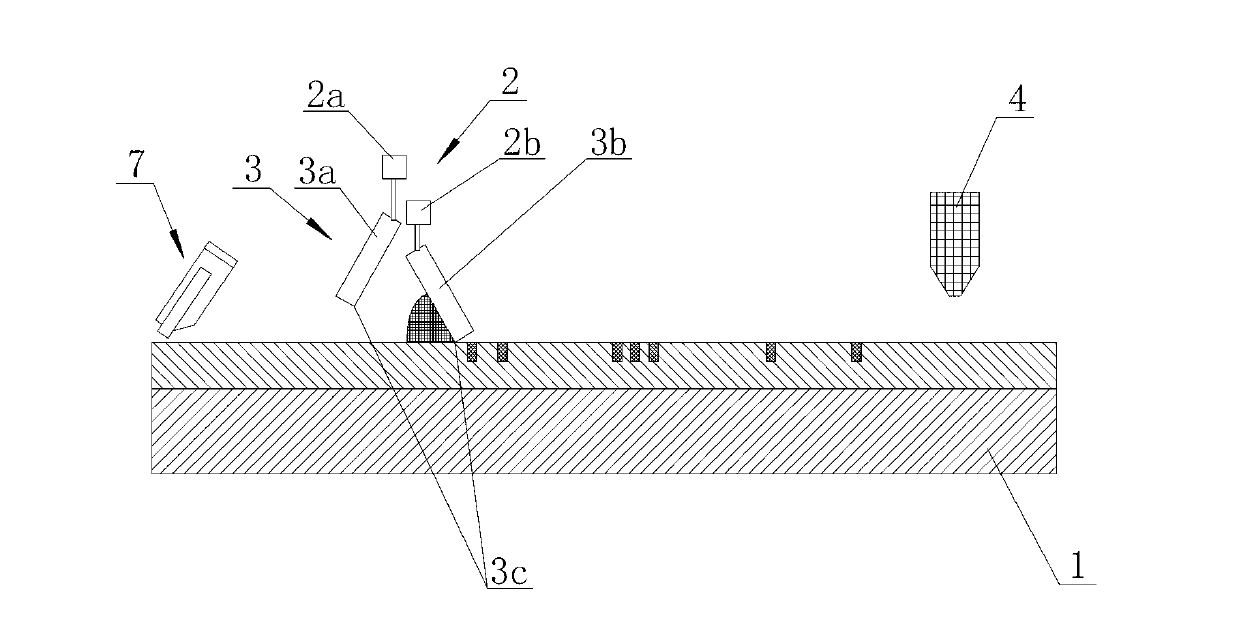

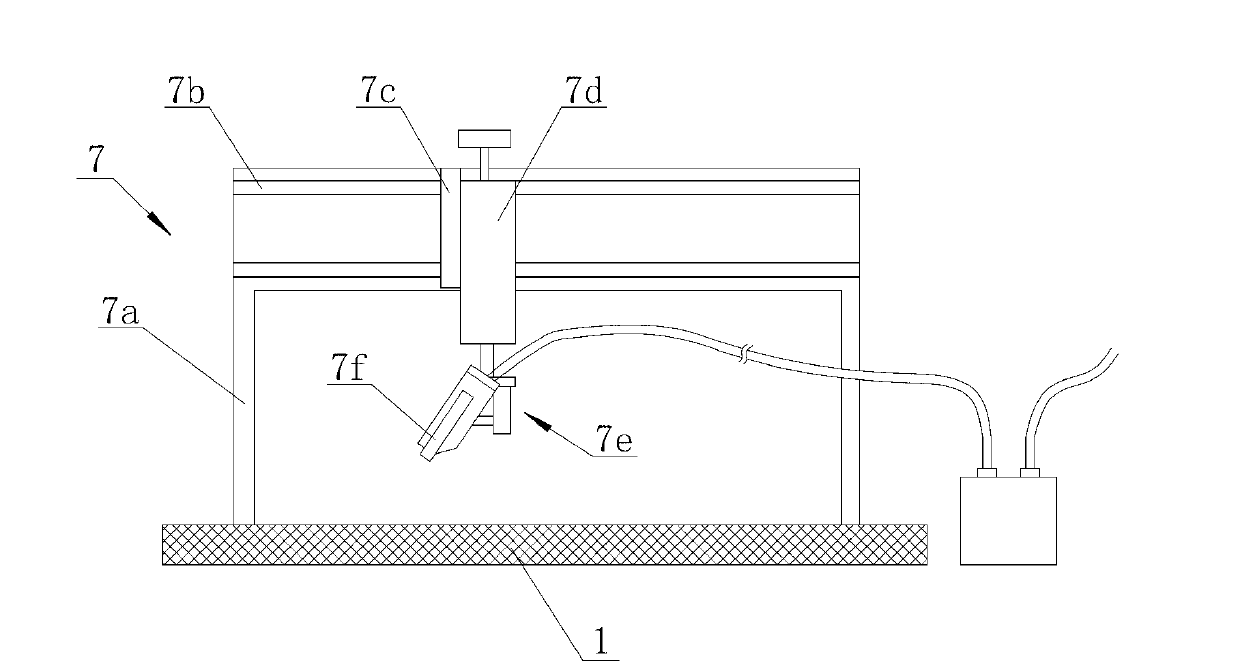

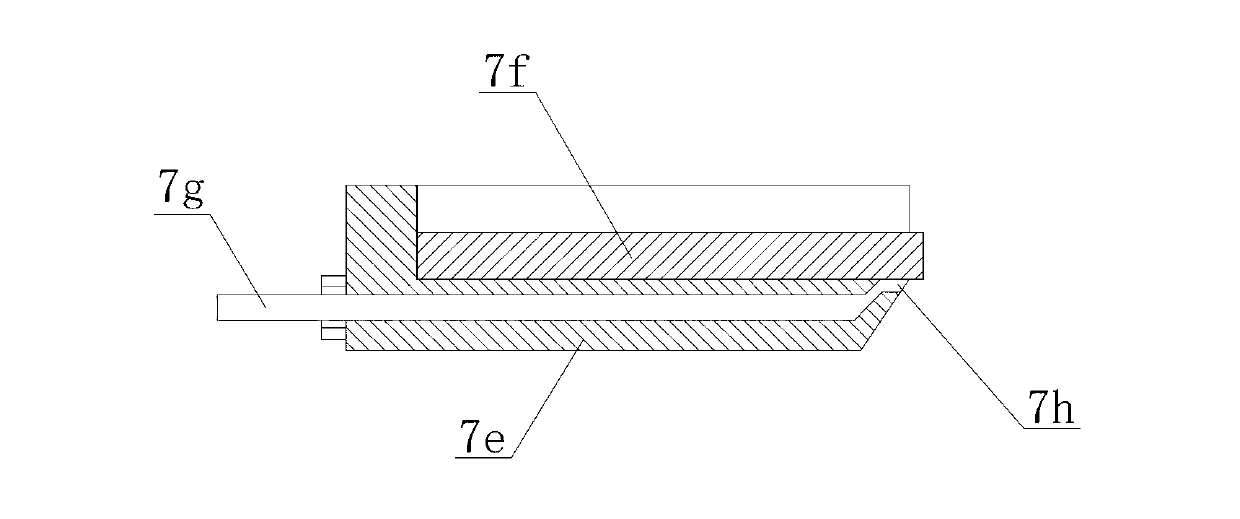

[0034] refer to Figure 1 to Figure 3 As shown, a plugging device for a base material of the present invention includes a support platform 1 for placing a base material to be plugged, and a vertical movement unit 2 is arranged above the support platform 1, and the vertical movement unit 2 can adopt a cylinder, a hydraulic pressure Lifting drive devices such as cylinders or servo motors, the vertical motion unit 2 is connected with horizontal drive devices, and the horizontal drive devices can adopt the commonly used screw rods in this area to cooperate with servo motors, or telescopic drives such as air cylinders and hydraulic cylinders. In this embodiment, the vertical motion unit 2 is a cylinder structure, the horizontal drive device is a servo motor drive structure, and a plug hole head 3 is provided at the free end of the cylinder structure 2, and the cylinder structure 2 provides 5 to 7 kgf for the plug hole head 3. The down force makes the plugging head 3 closely contact...

Embodiment 2

[0043] refer to Figure 4 As shown, a plugging device for a base material of the present invention has basically the same structure as that of Embodiment 1, except that the residual material recovery mechanism in this embodiment is a loading type residual material recovery mechanism 8, and the The material-loading type residual material recovery mechanism 8 is a material carrier plate that can be lifted and lowered, and a hollow part 8a with an area larger than the area of the base material to be plugged is provided on the material carrier plate 8, and the thickness of the material carrier plate 8 is 0.005~ 5mm. In this embodiment, the loading plate 8 is a stainless steel plate.

[0044] In addition, in this embodiment, the plugging material is heat-curing varnish, and the plugging method is roll-to-roll plugging. There are areas to be plugged with the same area at every distance on the substrate. The front end of the plugging device is connected to the unwinding device, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com