Whole-wheat soda biscuit and manufacture method thereof

A soda biscuit and its production method are applied in the fields of pre-baked dough processing, baking, baked food, etc., which can solve the problems of limiting the amount of whole wheat flour added, high production cost, cumbersome process, etc., and achieve easy preparation and feeding, and good quality , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

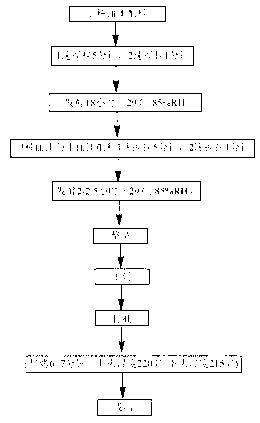

Method used

Image

Examples

Embodiment 1

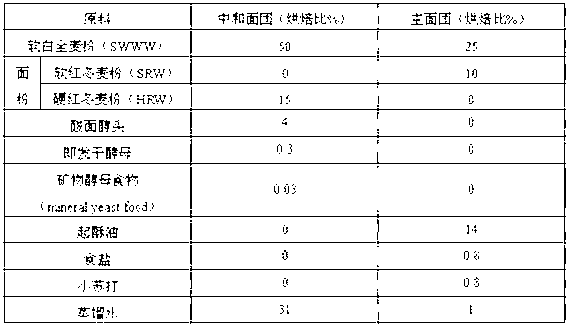

[0052] In terms of baking ratio, see Table 2 for the raw materials and proportions required for the preparation of the neutralized dough and the main dough.

[0053] Table 2

[0054]

[0055] Note: % means percentage by weight.

[0056] Among them, the specific amount of baking soda is determined according to the total titrated acid of the middle seed dough after the first fermentation, and the amount of baking soda determines the pH value of the final product. According to the principle that the pH value of commercial soda crackers is 7.0~8.0, after preliminary Experiments can determine the relationship between the amount of baking soda and the total titrated acid, see Table 3.

[0057] table 3

[0058]

[0059] The specific manufacturing process steps are as follows:

[0060] (1) Preparation of medium-sized dough: Weigh the raw materials required for making medium-sized dough according to the ratio shown in Table 1 and Table 2, that is, dry yeast, mineral yeast foo...

Embodiment 2

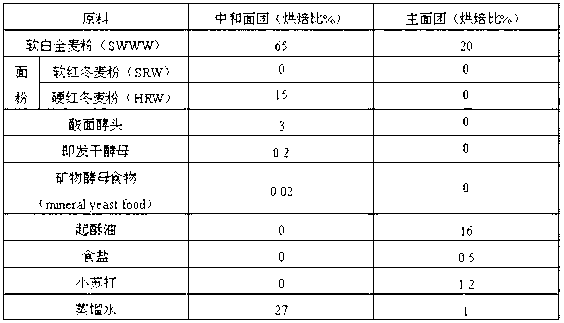

[0071] In terms of baking ratio, see Table 4 for the raw materials and proportions required for the preparation of the neutralized dough and the main dough.

[0072] Table 4

[0073]

[0074] Note: % means percentage by weight, and the specific dosage of baking soda refers to the standard in Table 3.

[0075] The specific manufacturing process steps are as follows:

[0076] (1) The preparation method of the middle seed dough is the same as in Example 1.

[0077] (2) The first fermentation: Put the middle dough made in step (1) in a proofer at 28°C and a relative humidity of 90% for 15 hours. After 15 hours, the softness of the middle dough will increase.

[0078] (3) The preparation method of the main dough is the same as in Example 1.

[0079] (4) Second fermentation: put the main dough prepared in step (3) in a proofing box at 28°C and a relative humidity of 90% for 2.5 hours until the pH value of the dough drops to 4.0.

[0080] (5) The specific operation methods of ...

Embodiment 3

[0084] In terms of baking ratio, see Table 5 for the raw materials and proportions required for the preparation of the neutralized dough and the main dough.

[0085] table 5

[0086]

[0087] Note: % means percentage by weight, and the specific dosage of baking soda refers to the standard in Table 3.

[0088] The specific manufacturing process steps are as follows:

[0089] (1) The preparation method of the middle seed dough is the same as in Example 1.

[0090] (2) The first fermentation: Put the middle dough made in step (1) in a proofer at 30°C and a relative humidity of 80% to ferment for 20 hours. After 20 hours, the softness of the middle dough increases.

[0091] (3) Preparation of the main dough: weigh the raw materials required for making the main dough according to the ratio shown in Table 1 and Table 2,

[0092] Mix the above fermented Chinese dough with the remaining soft white whole wheat flour, distilled water, shortening, salt and baking soda (baking sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com