Amine liquid run loss comprehensive control method and device in desulfurization solvent regeneration process

A technology of regeneration process and comprehensive prevention and control, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as running loss of amine liquid and prolonging the running time of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: The regeneration process of desulfurization solvent in the natural gas desulfurization unit of the first combined unit of Puguang Natural Gas Purification Plant flow intensified process

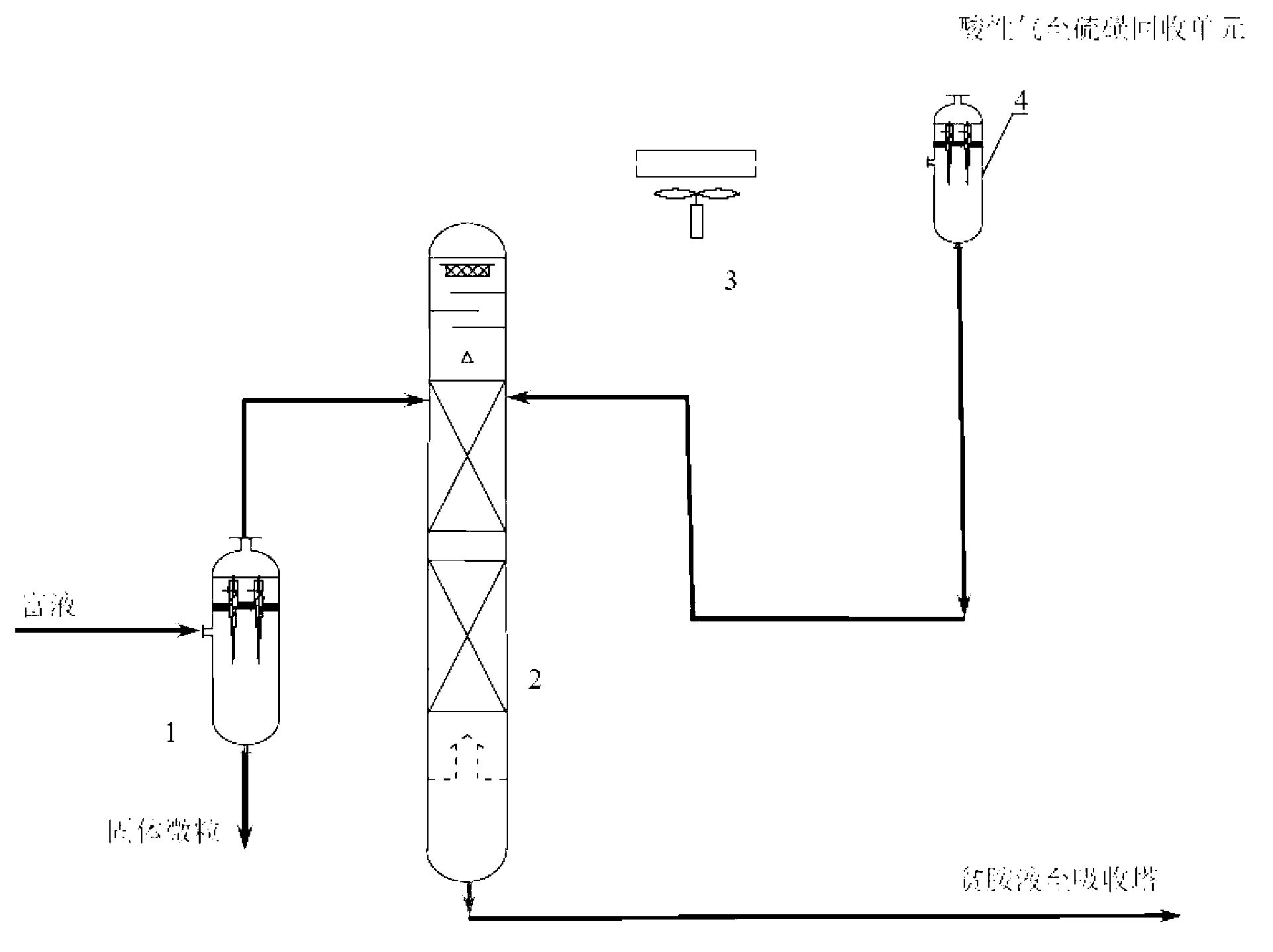

[0043] Process flow: such as figure 1 shown.

[0044] The processing capacity of the device is 2×300×10 4 N m 3 / d, H in high-sulfur natural gas 2 S content is 13-18% (v), organic sulfur content is 340.6mg / m 3 , CO 2 The content is 810% (v).

[0045] The main operating medium of the amine liquid regeneration tower is amine liquid and acid gas, the operating temperature is 128°C, the operating pressure is 0.12MPa, the liquid phase flow rate is 778209kg / h, and the liquid phase density is 957.9kg / m 3 , the gas phase flow rate is 78344kg / h, and the gas phase density is 1.20kg / m 3 , the minimum pressure drop (in clean state) of follow-up equipment is 0.02MPa, and the maximum pressure drop (in fouling state) is 0.1MPa. The micro-swirl core tube adopts the HL / S type liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com