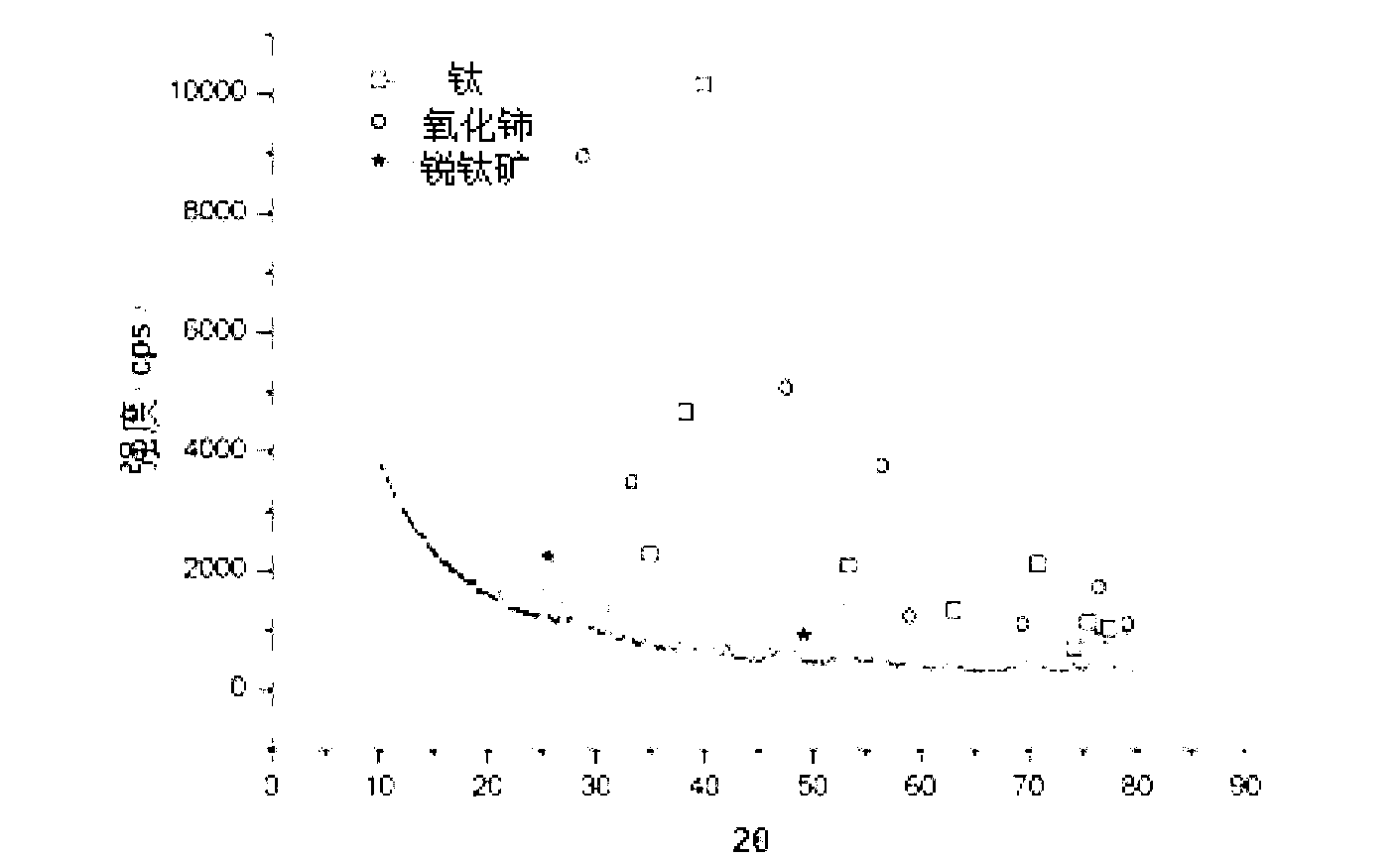

Preparation method of nano TiO2 film modified by metal oxide

An oxide and metal technology, applied in the field of preparation of metal oxide modified nano-TiO2 thin film materials, can solve the problems of reducing specific surface area, difficult process control, reducing reaction area, etc., achieves high photocatalytic degradation rate, is conducive to industrial production, The effect of easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Raw materials: 25mm×15mm×2mm rectangular pure titanium sheet, 10g / L Na 3 PO 4 Solution, 1g / L NaF solution, 5mmol vanadium pentoxide.

[0015] Steps: Coat the surface of the pretreated titanium sheet with 5 mmol of vanadium pentoxide with viscous polyvinyl alcohol after heating, and after drying, place the sample directly on the micro-arc oxidation equipment for micro-arc oxidation (experimental parameters are: Voltage 420V, preparation time 30min, Na in phosphate electrolyte system 3 PO 4 The concentration is 10g / L, the NaF concentration is 1g / L, and the electrolysis temperature is controlled below 35°C), and finally the prepared nano-TiO 2 The film was rinsed with deionized water and dried.

Embodiment 2

[0017] Raw materials: 25mm×15mm×2mm rectangular pure titanium sheet, 10g / L Na 3 PO 4 Solution, 1g / L NaF solution, 20mmol silver oxide.

[0018] Steps: Coat the surface of the pretreated titanium sheet with 20mmol silver oxide with viscous polyvinyl alcohol after heating, and after drying, place the sample directly on the micro-arc oxidation equipment for micro-arc oxidation (experimental parameters: voltage 420V , the preparation time is 30min, Na in the phosphate electrolyte system 3 PO 4 The concentration is 10g / L, the NaF concentration is 1g / L, and the electrolysis temperature is controlled below 35°C), and finally the prepared nano-TiO 2 The film was rinsed with deionized water and dried.

Embodiment 3

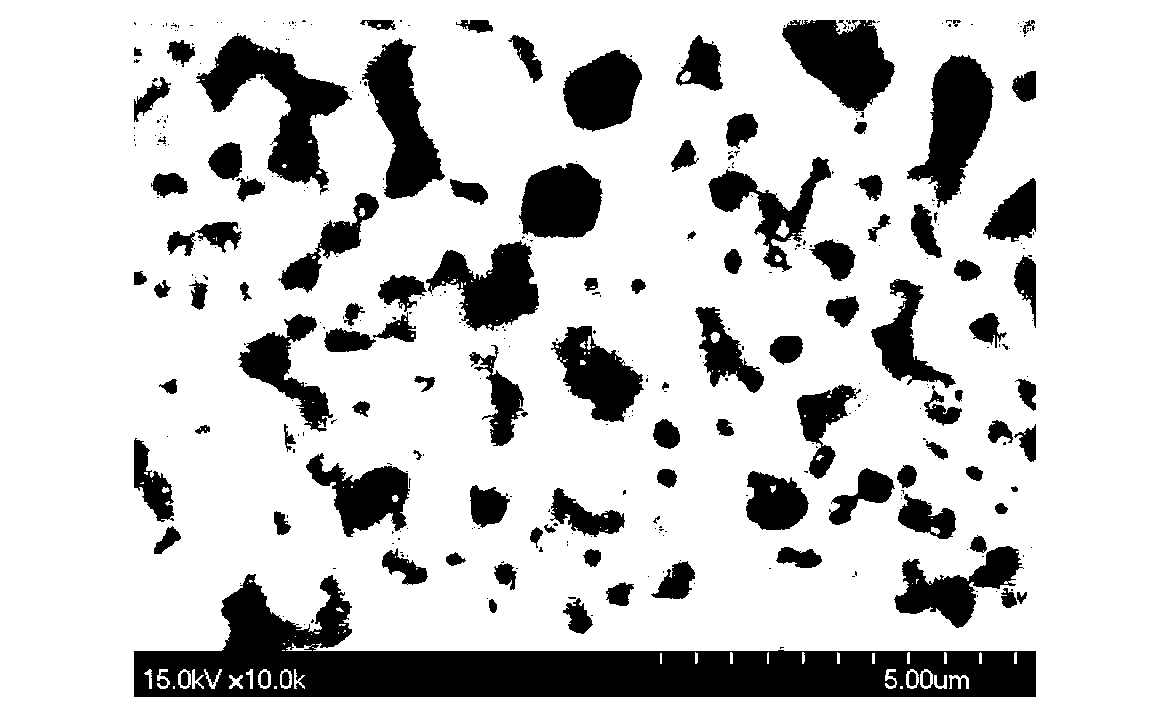

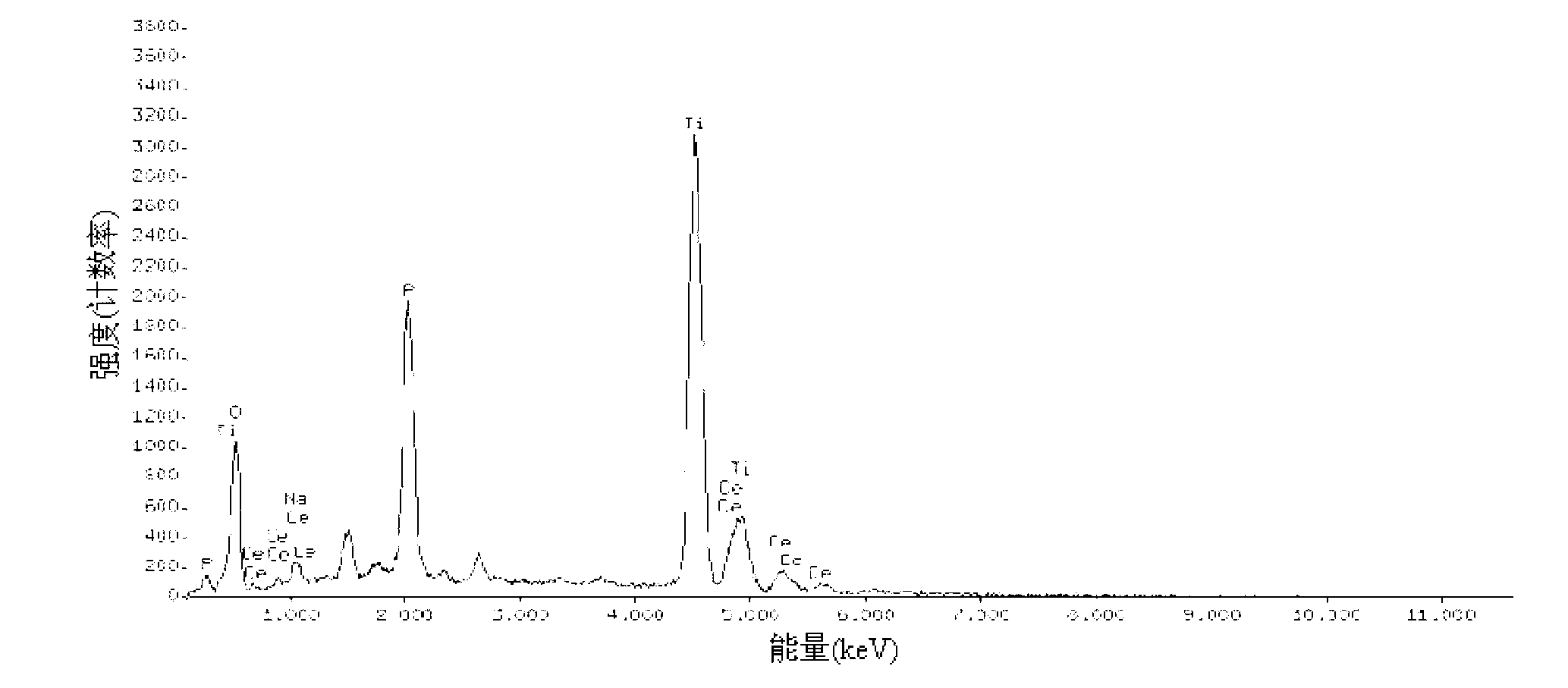

[0020] Raw materials: 25mm×15mm×2mm rectangular pure titanium sheet, 10g / L Na 3 PO 4 Solution, 1g / L NaF solution, 10mmol cerium oxide.

[0021] Steps: Coat the surface of the pretreated titanium sheet with 10mmol of cerium oxide with viscous polyvinyl alcohol after heating. After drying, place the sample directly on the micro-arc oxidation equipment for micro-arc oxidation (experimental parameters: voltage 420V , the preparation time is 30min, Na in the phosphate electrolyte system 3 PO 4 The concentration is 10g / L, the NaF concentration is 1g / L, and the electrolysis temperature is controlled below 35°C), and finally the prepared nano-TiO 2 The film was rinsed with deionized water and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com