A dry cleaning method based on ultraviolet light

A technology of dry cleaning and ultraviolet light, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning flexible objects, etc., can solve the problems of workers endangering the environment, safety problems, pollution, etc., to avoid secondary pollution, cleaning Good net effect, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

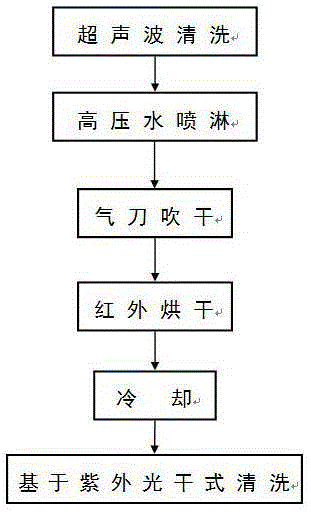

[0026] Taking the TFT-LCD glass substrate as an example, the process flow chart of this method is as follows figure 1 As shown, the specific steps are: the first step, ultrasonic cleaning, the TFT-LCD glass substrate to be cleaned is sent to the ultrasonic cleaning device through the input conveyor, the ultrasonic frequency is controlled at 28KHz-40KHz, the handling speed is 3m / min, pure The water flow rate is 30L / min, at this time, the cleaning effect is the best. The second step is high-pressure water spraying. After the ultrasonic cleaning is completed, the glass substrate is still passed through the high-pressure water spraying device at a speed of 3m / min, and the high-pressure water pump pressurizes the cleaning water (pure water) to 1.5Mpa. The third step is to dry the air knife. After the wet cleaning is completed, the glass substrate needs to be dried for the subsequent process. The high-speed gas blown from the gap is used to remove the moisture on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com