Soybean wastewater biochemical treatment process and device

A biochemical treatment device, soybean product wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of narrow range of low dissolved oxygen and insufficient degradation efficiency of COD and N Ideal and other problems, to achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Embodiment, a certain bean product factory waste water treatment

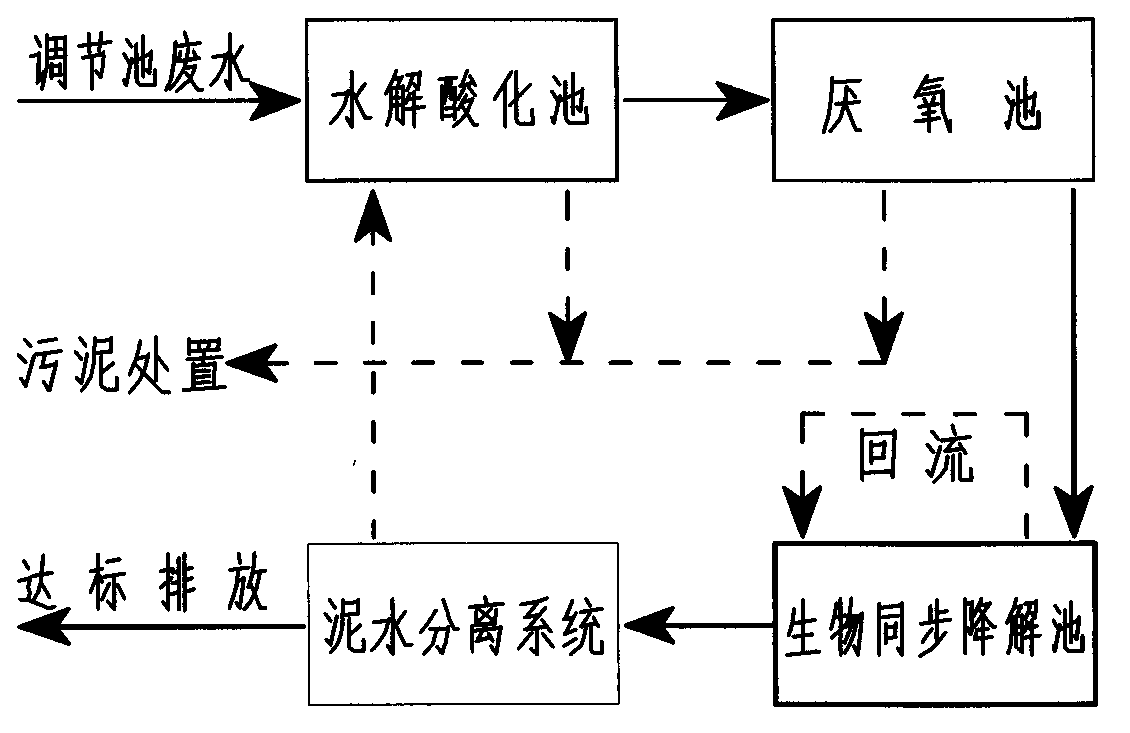

[0048] The original process and equipment of wastewater treatment are "regulating tank + physical and chemical sedimentation tank + anaerobic tank + aerobic tank + physical and chemical air flotation tank", the effluent ammonia nitrogen and total nitrogen exceed the standard, the sludge output is large, and the treatment cost is high. Apply the present invention to carry out process adjustment practice.

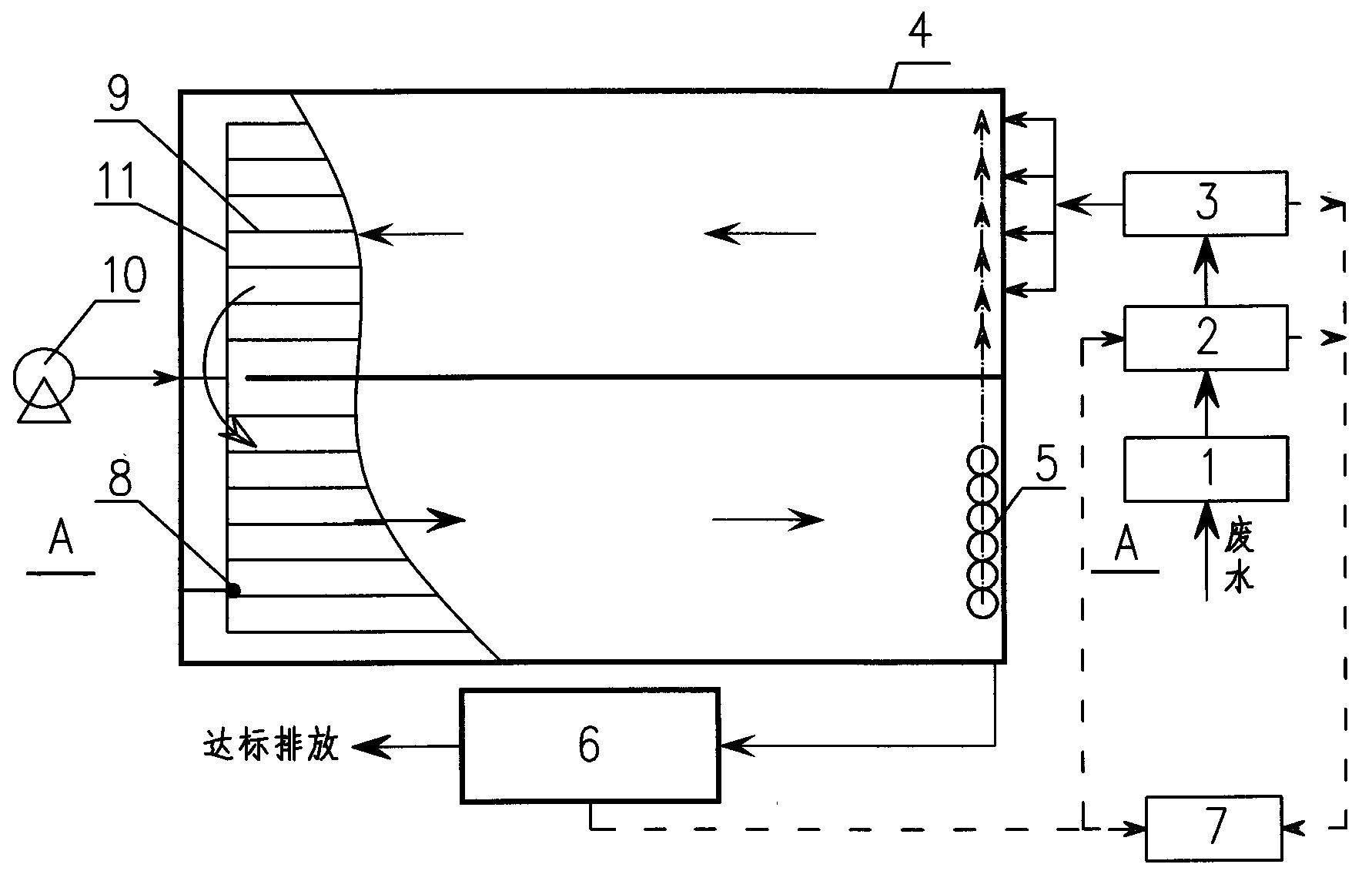

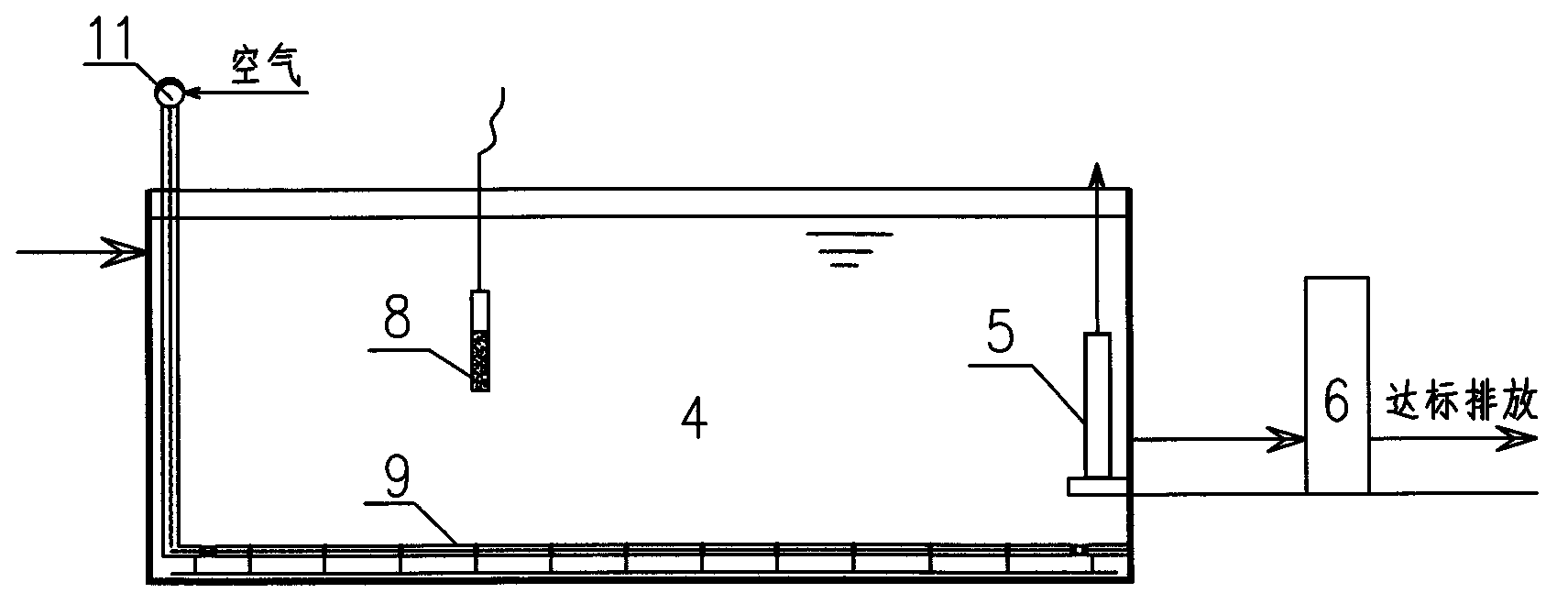

[0049] Adjusted process and equipment: "Regulating pool + UBF pool + EGSB pool + biosynchronous degradation pool".

[0050] Adjusted process and device parameters: UBF pool: biochemical residence time 12h, effluent COD Cr 8450mg / L, COD Cr Removal rate 16%, COD Cr Remove volume load 3.1KgCOD / m 3 .d; EGSB pool: biochemical residence time 26h, pH6.8, effluent COD Cr 1960mg / L, COD Cr 77% removal rate, COD Cr Remove volume load 6.0KgCOD / m 3 .d; Biological synchronous degradation tank: biochemical res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com