Water-based water-reduction type mortar tackifier, as well as preparation method and application thereof

A water-reducing and tackifier technology, applied in the field of building materials, can solve problems such as failure to improve the mortar production process, and achieve the effect of improving water-reducing effect, reducing production labor, and facilitating large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

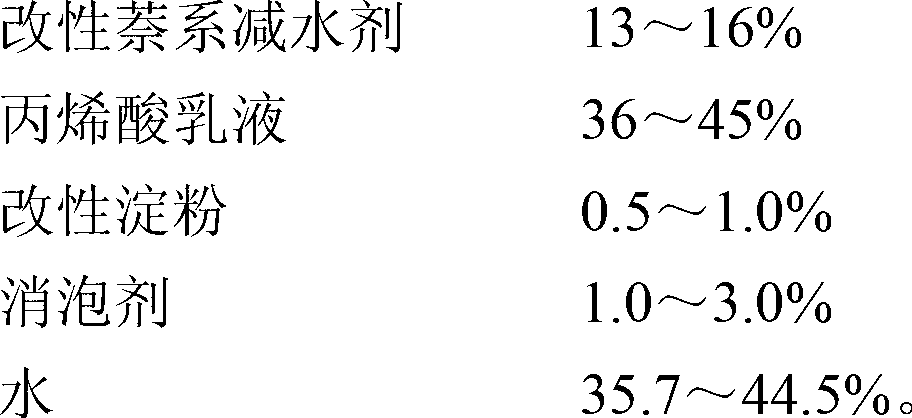

Embodiment 1

[0033] (1) Put 26.9g of industrial naphthalene (95wt%) into the reaction kettle and heat up to 130°C to melt. After the naphthalene is melted, heat up to 150°C, and add 24g of concentrated sulfuric acid with a mass percentage of 98% for 0.5 hours. After the dropwise addition, keep the temperature for 3 hours, lower the temperature to 90°C, add 9.12g of polyethylene glycol benzoate and 16.2g of formaldehyde solution with a mass percentage of 37%, keep the temperature for 1.5 hours, cool to 40°C, and use the mass percentage Adjust the pH of the 30% NaOH solution to 7 to obtain a modified naphthalene-based water reducer.

[0034] (2) Mix 10g of the modified naphthalene-based water reducer in step (1), 36g of acrylic acid emulsion (effective solid content: 60wt%), 0.2g of carboxymethyl starch, 0.5g of water-based defoamer and 53.3g of water, and stir Evenly, the water-based water-reducing mortar viscosifier can be obtained.

Embodiment 2

[0036] (1) Put 26.9g of industrial naphthalene (95wt%) into the reactor and heat up to 130°C to melt. After the naphthalene is melted, heat up to 150°C, and add 36g of concentrated sulfuric acid with a mass percentage of 98% for 0.5 hours. , after the dropwise addition, keep the reaction for 2.5 hours, cool down to 100°C, add 18.2g of polyethylene glycol benzoate and 21.6g of formaldehyde solution with a mass percentage of 37%, keep the heat for 1.0 hours, cool down to 50°C, and use the mass percentage Adjust the pH of the 20% NaOH solution to 7.5 to obtain a modified naphthalene-based water reducer.

[0037] (2) Mix 13g of the modified naphthalene-based water reducer in step (1), 50g of acrylic acid emulsion (effective solid content: 40wt%), 0.3g of hydroxyethyl starch, 1.0g of water-based defoamer and 35.7g of water, and stir Evenly, the water-based water-reducing mortar viscosifier can be obtained.

Embodiment 3

[0039] (1) Put 26.9g of industrial naphthalene (95wt%) into the reaction kettle and heat up to 140°C to melt. After the naphthalene is melted, heat up to 150°C, and add 35g of concentrated sulfuric acid with a mass percentage of 98% for 0.8 hours. , after the dropwise addition, keep the temperature for 2.0 hours, cool down to 95°C, add 10g of polyethylene glycol benzoate and 16g of formaldehyde solution with a mass percentage of 37%, keep the heat for 1.5 hours, cool down to 45°C, and use a mass percentage of 40% % NaOH solution to adjust the pH to 8 to obtain a modified naphthalene-based water reducer.

[0040] (2) Mix 16g of the modified naphthalene-based water reducer in step (1), 30g of acrylic acid emulsion (effective solid content: 50wt%), 0.1g of hydroxypropyl starch, 1.5g of water-based defoamer and 52.4g of water, and stir Evenly, the water-based water-reducing mortar viscosifier can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com