Solvent-free polyurethane compound adhesive and preparation method thereof

A solvent-free polyurethane and composite adhesive technology, which is applied in the field of polymer chemistry, can solve the problems that the composite film does not meet the retort sterilization resistance, poor high temperature resistance and durability, and the peeling strength needs to be improved, and achieves good adhesion. , The effect of good adhesion and increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the preparation of curing agent-1

[0045] Heat 120 parts of polyoxypropylene diol with a molecular weight of 400 to 120°C and dehydrate for 1 hour at a vacuum of 0.25KPa; when the temperature drops to 40°C, stir and add 40 parts of epoxy resin (E-44), 30 parts of trimellitic anhydride, 10 After stirring evenly, raise the temperature to 60°C and heat and stir for 3 hours to obtain an epoxy resin-modified polyether polyol. Hereinafter referred to as curing agent-1.

Embodiment 2

[0046] Embodiment 2: the preparation of curing agent-2

[0047] Heat 105 parts of polyoxypropylene triol with a molecular weight of 300 to 125°C and dehydrate for 1 hour at a vacuum of 0.25KPa; when the temperature drops to 40°C, stir and add 27 parts of epoxy resin (E-44), 15 parts of trimellitic anhydride, 3 After stirring evenly, heat up to 100°C and stir for 2.5 hours to prepare epoxy resin-modified polyether polyol. Hereinafter referred to as curing agent-2.

Embodiment 3

[0048] Embodiment 3: the preparation of curing agent-3

[0049]Heat 40 parts of polyoxypropylene triol with a molecular weight of 300 and 120 parts of polyoxypropylene diol with a molecular weight of 400 to 125°C, dehydrate for 2 hours at a vacuum of 0.25KPa; drop the temperature to 45°C, and add 26 parts of epoxy Resin (E-44), 10 parts of trimellitic anhydride, and 4 parts of phosphoric acid were evenly stirred, then heated to 120°C and stirred for 2 hours to prepare epoxy resin-modified polyether polyol. Hereinafter referred to as curing agent-3.

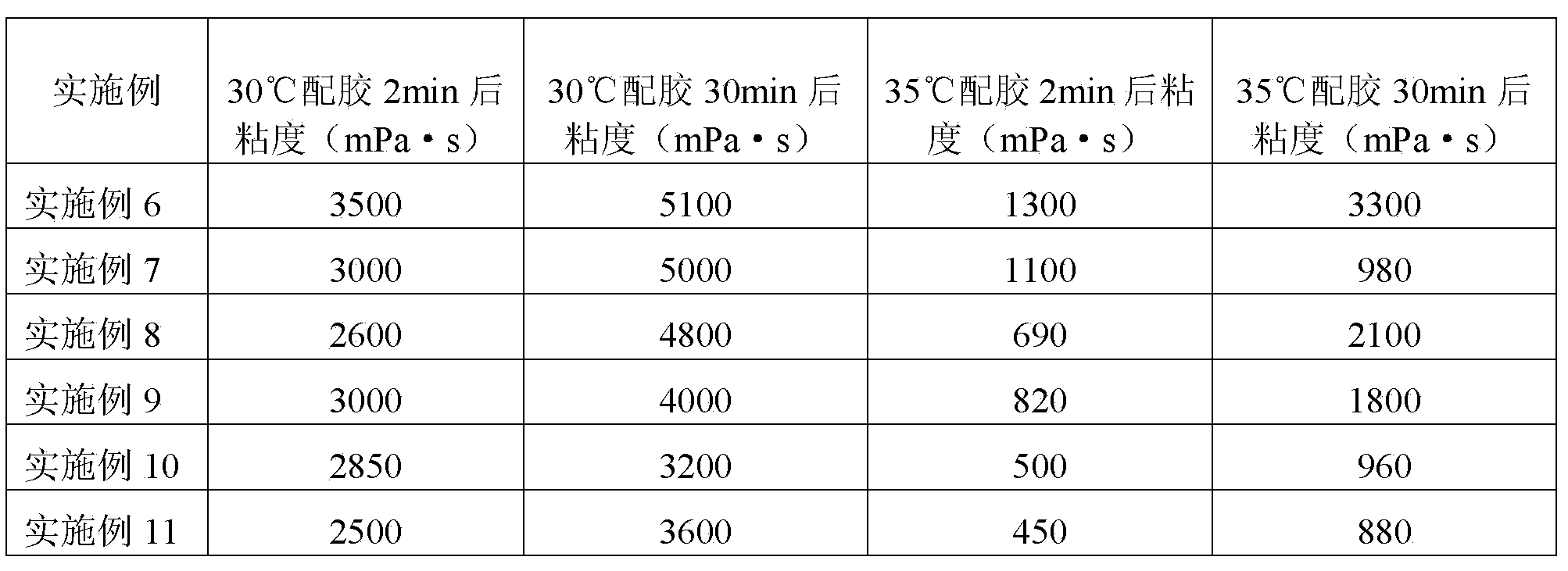

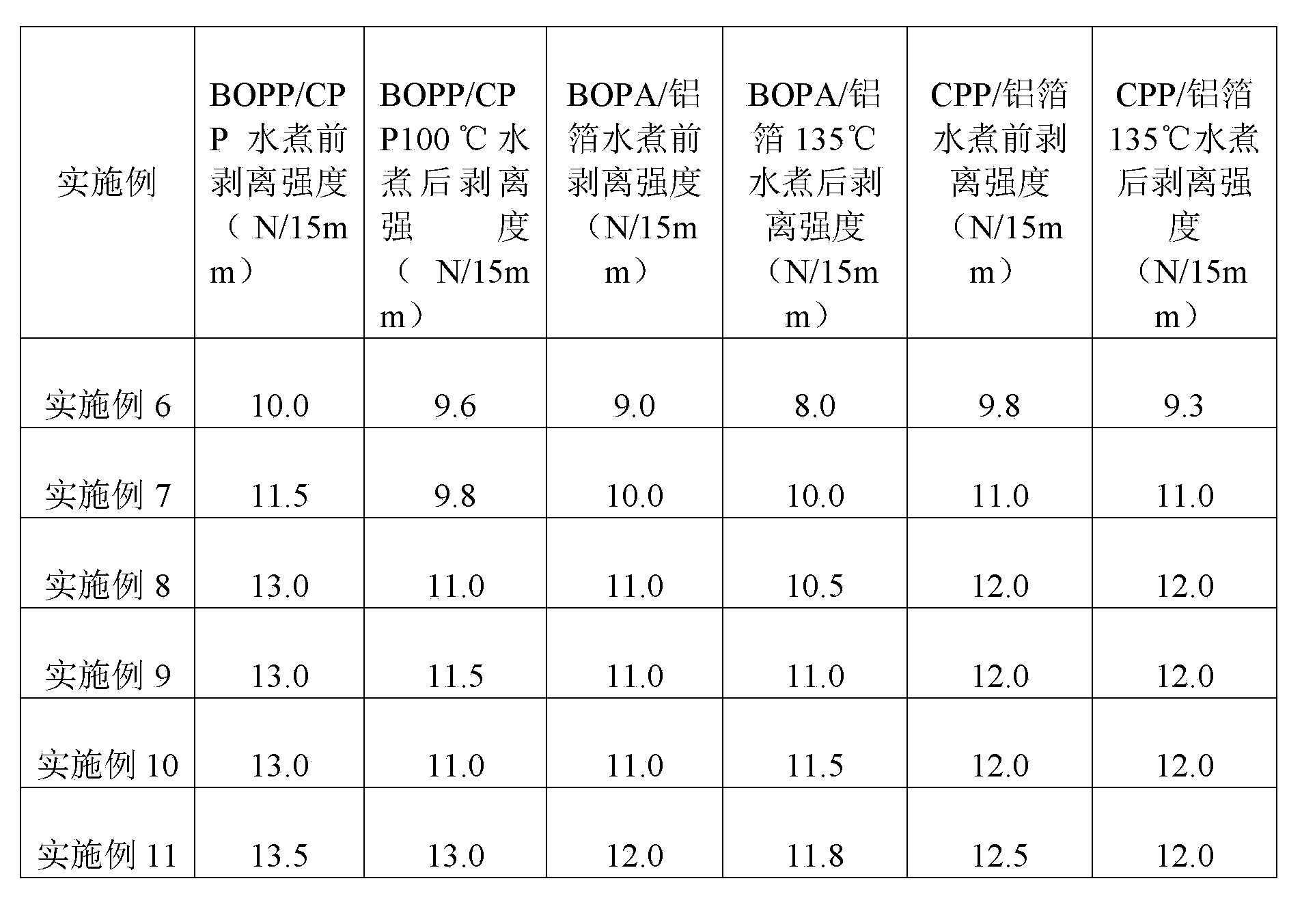

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com