Lubricating oil composition for refrigerator

A technology of lubricating oil composition and refrigerator, applied in lubricating composition, petroleum industry, materials for heat exchange, etc., can solve problems such as low temperature stability research and manufacturing difficulties, and achieve long-term low temperature stability and good lubricity. , the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The present invention will be specifically described below using examples.

[0052] The test methods for the esters prepared in the present examples and comparative examples are described below:

[0053] According to JIS K-2283, the kinematic viscosity at 40 degreeC and 100 degreeC was measured using the Cannon-Fenske viscometer, and the viscosity index was calculated.

[0054] Measured based on JIS C-2101.

[0055] Measured in accordance with JIS K-0070.

[0056] Measured based on JOCS 2.2.1.4-1996.

[0057] According to JIS C-2101, the volume resistivity (TΩ·m) at 25 degreeC was measured.

[0058] Measured in accordance with JIS K-2269.

[0059] Seal 400g of the sample with the water content below 100ppm into a stainless steel square tank, place it in a low-temperature storage at -28°C for 1000 hours, and observe whether there is crystallization by visual method.

[0060] Add 0.6g of sample (ester) and 2.4g of refrigerant R-134a with dry ice to a thick-wa...

Synthetic example 1

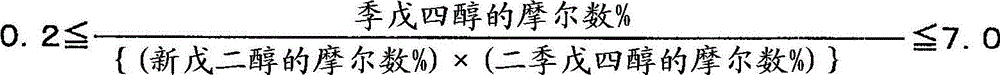

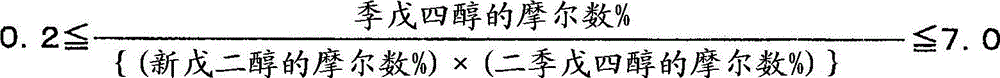

[0063] Synthesis Example 1: Preparation of Esters

[0064] Put the mixed alcohol shown in Table 1 and the saturated monocarboxylic acid into the 1 liter 4-necked flask that has installed thermometer, nitrogen introduction pipe, stirrer and cooling pipe, the equivalent ratio of the hydroxyl group of mixed alcohol and the carboxyl group of saturated monocarboxylic acid is 1:1.1, under a nitrogen flow, the reaction was carried out under normal pressure at 220° C. while distilling off the reaction water. The hydroxyl value was monitored during the reaction, and the reaction was stopped when it was lower than 2.0 mg KOH / g. Thereafter, stripping was performed under a reduced pressure of 1 to 5 kPa to remove unreacted carboxylic acid over 1 hour. Aqueous potassium hydroxide solution was added to the obtained reaction mixture to wash with water. The water washing process was repeated 5 times to make the pH of the drain water neutral. Then, the obtained ester layer was dehydrated un...

Synthetic example 2~7

[0066] Esters (esters B to G) were obtained in the same manner as in Example 1, except that the mixed alcohols and saturated monocarboxylic acids shown in Table 1 were used. For each ester, the kinematic viscosity at 40°C and 100°C was measured by the method described above. The results are shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com