Soybean peptide and industrial production method and application of soybean peptide

A production method and soybean peptide technology, applied in soybean peptide and its industrialized production method and application field, can solve problems such as food safety concerns, and achieve the effect of solving color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

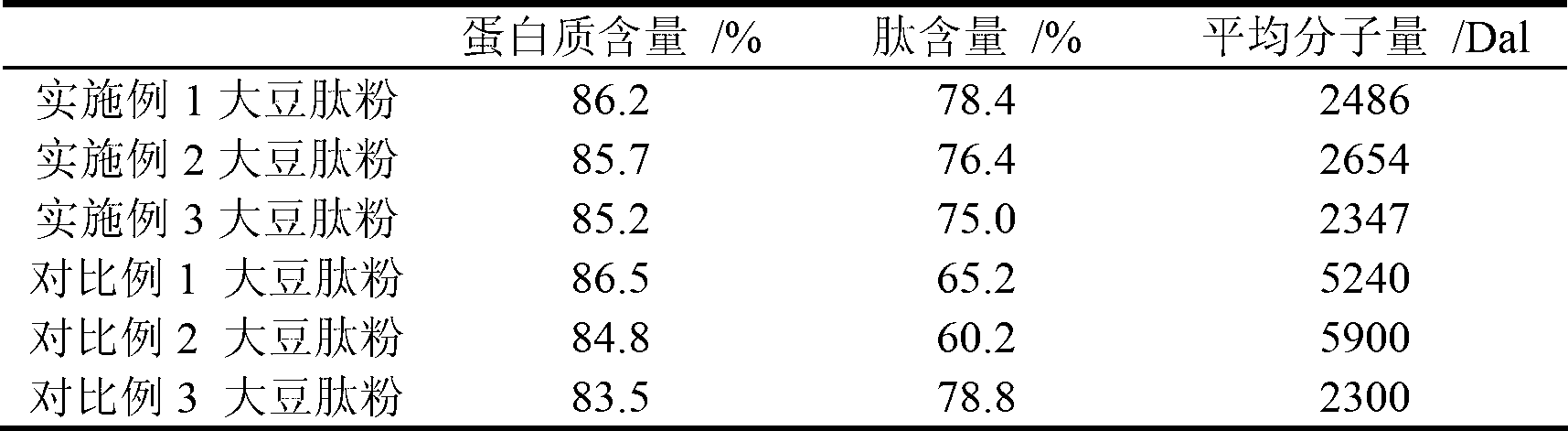

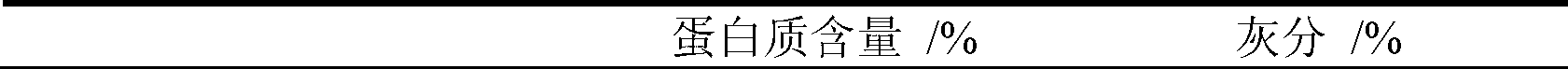

Examples

Embodiment 1

[0045] (1) Pickling: Take 100kg of soybean protein isolate (commercially available), stir and dissolve it in 600L of water at a temperature of 55°C at a speed of 100rpm, adjust the pH value to 4.2 with citric acid, and remove the supernatant by centrifugation in a decanter centrifuge , the slurry is pickled once more and separated;

[0046] (2) Disintegration and neutralization: disintegrate the slurry, dissolve it in 800L of water at a temperature of 55°C, and adjust its pH value to 7.2 with sodium hydroxide;

[0047] (3) Enzymolysis: keep at 55°C, add 3kg of alkaline protease (Alcalase2.4L, produced by Novozymes) and 0.1kg of compound flavor protease (Flavourzyme1000L, produced by Novozymes) for enzymolysis, and enzymolysis for 3 hours; Add 1 kg of neutral protease (Neutrase 0.8L, produced by Novozymes) and perform enzymatic hydrolysis for 4 hours.

[0048] (4) Acid precipitation, enzyme inactivation, separation: then adjust the pH value to 4.5 with citric acid, raise the t...

Embodiment 2

[0052] (1) Pickling: Take 100kg of soybean protein isolate, stir and dissolve it in 600L of water at a temperature of 55°C at 150rpm, adjust the pH value to 4.5 with citric acid, remove the supernatant by centrifugation, continue to pickle the slurry once, and separate;

[0053] (2) Disintegration and neutralization: disintegrate the slurry, dissolve it in 800L of water at a temperature of 55°C, and adjust its pH value to 7.4 with sodium hydroxide;

[0054](3) Enzymolysis: keep at 53°C, add 3kg of alkaline protease (Alcalase2.4L, produced by Novozymes), add 0.5kg of compound flavor protease (Flavourzyme1000L, produced by Novozymes) for enzymolysis, and enzymolysis for 3.5 hours, Add 1 kg of neutral protease (Neutrase 0.8L, produced by Novozymes), and enzymatically hydrolyze for 4.5 hours;

[0055] (4) Acid precipitation, enzyme inactivation, separation: adjust the acidity to 4.5 with citric acid, raise the temperature to 85°C, centrifuge to take the supernatant after 15 minute...

Embodiment 3

[0059] (1) Pickling: Take 100kg of soybean protein isolate, stir and dissolve at 130rpm in 600L of water at a temperature of 55°C, use hydrochloric acid to make the pH value 4.8, centrifuge to remove the supernatant, continue to pickle the slurry once, and separate;

[0060] (2) Disintegration and neutralization: disintegrate the slurry, dissolve it in 800L of water at a temperature of 55°C, and adjust its pH value to 7.4 with sodium hydroxide;

[0061] (3) Enzymolysis: Keep at 58°C, add 1kg of alkaline protease (Alcalase2.4L, produced by Novozymes), 1.0kg of compound flavor protease (Flavourzyme1000L, produced by Novozymes) for enzymolysis, enzymatic hydrolysis for 4 hours, add 3kg neutral protease (Neutrase0.8L, produced by Novozymes), enzymolysis for 5 hours;

[0062] (4) Acid precipitation, enzyme inactivation, separation: adjust the acidity to 4.5 with hydrochloric acid, raise the temperature to 85°C, and after 15 minutes, centrifuge to take the supernatant;

[0063] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com