Novel roadbed structure for phreatic high inland sulphate salty soil

A saline soil and water level technology, applied in the direction of roads, roads, climate change adaptation, etc., can solve problems such as subsidence, salt heaving, adverse effects on the surrounding environment, etc. The effect of reducing salt migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

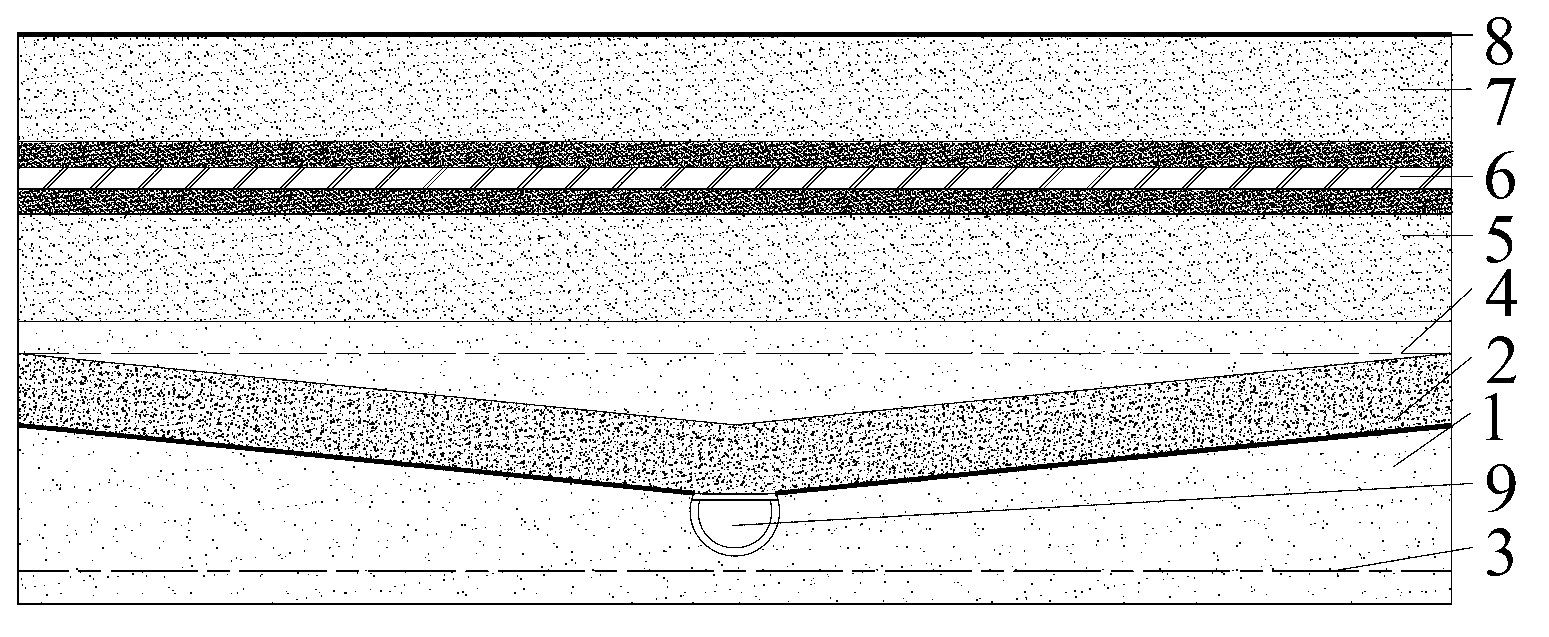

[0017] (1) Add 1m to both sides of the designed pavement width to remove the salt crust. The excavation depth of the central axis is controlled by reducing the depth of groundwater by 30cm. Rolling is carried out under optimal water content conditions to achieve maximum compaction.

[0018] (2) Excavate a 50×50 cross-section groove downward at the central axis of the base, and then build a U-shaped cross-section concrete trench with a height of 30cm, a width of 30cm, and a thickness of 5cm or lay a 30×30 prefabricated U-shaped pipe. The longitudinal slope is uniform and not less than 1%, and both sides are backfilled to the notch, and the drainage pipe is covered with a permeable board.

[0019] (3) Lay anti-filter geotextiles on the surface of the base, and then lay 20cm, uniformly graded sand and gravel with a particle size of 1-50mm at one time and compact them to form an 8° inclination to the central drainage ditch, and wrap the sides with gravel soil To the excavation si...

Embodiment 2

[0024] (1) Add 1m to both sides of the designed pavement width to remove the salt crust. The excavation depth of the central axis is controlled by reducing the buried depth of groundwater by 30cm. Rolling is carried out under optimal water content conditions to achieve maximum compaction.

[0025] (2) Excavate a 50×50 cross-section groove downward at the central axis of the base, and then build a U-shaped cross-section concrete trench with a height of 30cm, a width of 30cm, and a thickness of 5cm or lay a 30×30 prefabricated U-shaped pipe. The consistent longitudinal slope is not less than 1%, backfill to the notch on both sides, and cover the drainage ditch with a permeable board.

[0026] (3) Lay anti-filter geotextiles on the surface of the base, and then lay 30cm, uniformly graded sand and gravel with a particle size of 1-50mm at one time and compact them to form a 7° inclination to the central drainage ditch, with gravel soil on both sides. To the sideline of the excavat...

Embodiment 3

[0031] (1) Add 1m to both sides of the designed pavement width to remove the salt crust. The excavation depth of the central axis is controlled by reducing the buried depth of groundwater by 50cm. Rolling is carried out under optimal water content conditions to achieve maximum compaction.

[0032] (2) Excavate a 50×50 cross-section groove downward at the central axis of the base, and then build a U-shaped cross-section concrete trench with a height of 30cm, a width of 30cm, and a thickness of 5cm or lay a 30×30 prefabricated U-shaped pipe. The consistent longitudinal slope is not less than 1%, backfill to the notch on both sides, and cover the drainage ditch (pipe) with a permeable sand barrier.

[0033] (3) Lay sand and gravel with a total thickness of 60cm and a uniform particle size of 1-50mm on the surface of the base twice and compact it to form a 5° inclination to the central drainage ditch, and wrap the edges with gravel soil on both sides until the excavation sideline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com