Reactor and method for filtering composite plasma catalytic treatment diesel engine PMs (particulate matters)

A diesel engine, catalytic treatment technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of diesel engine back pressure rise, filter blockage, melting, etc., to improve air quality and realize on-site cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

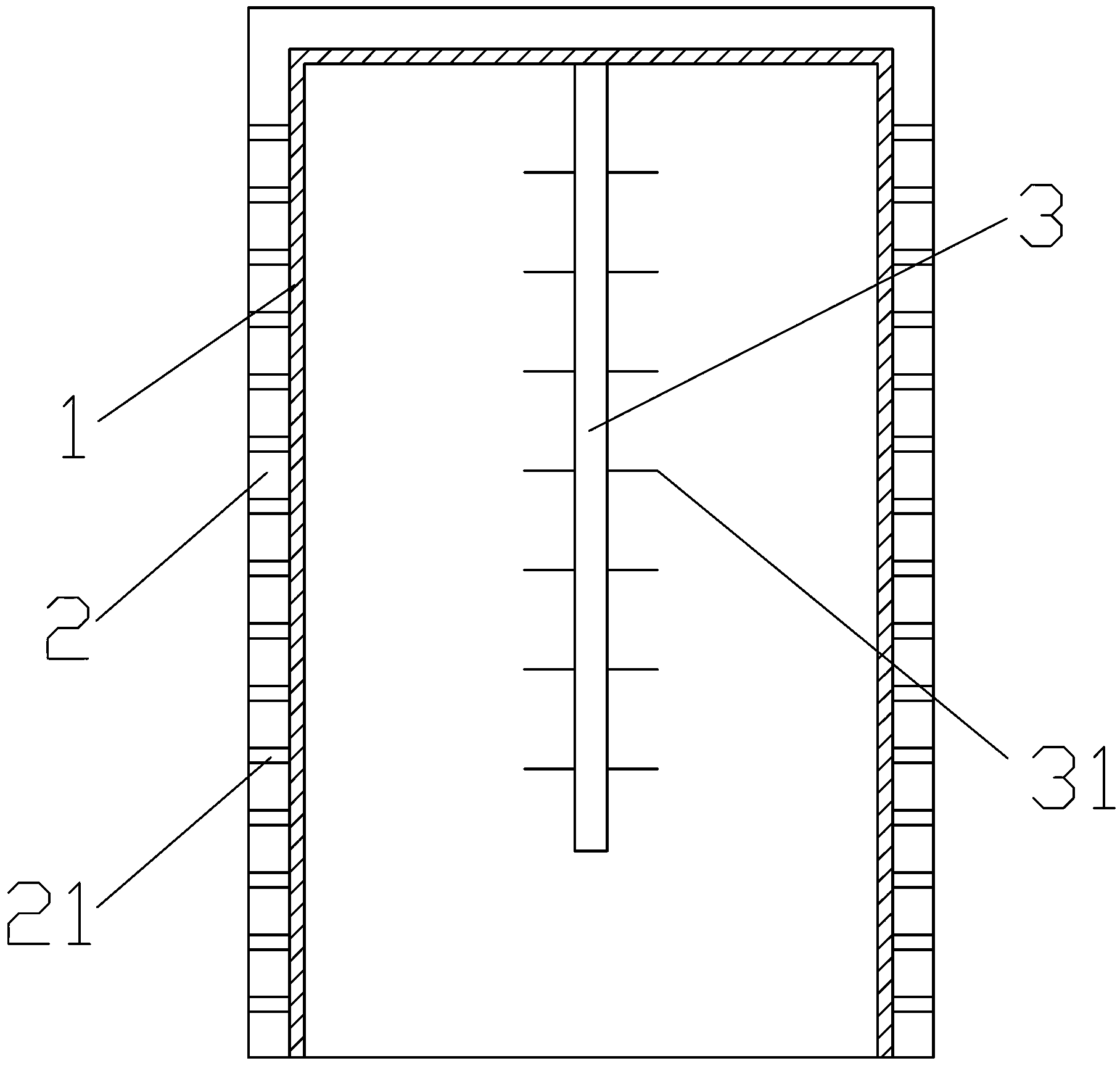

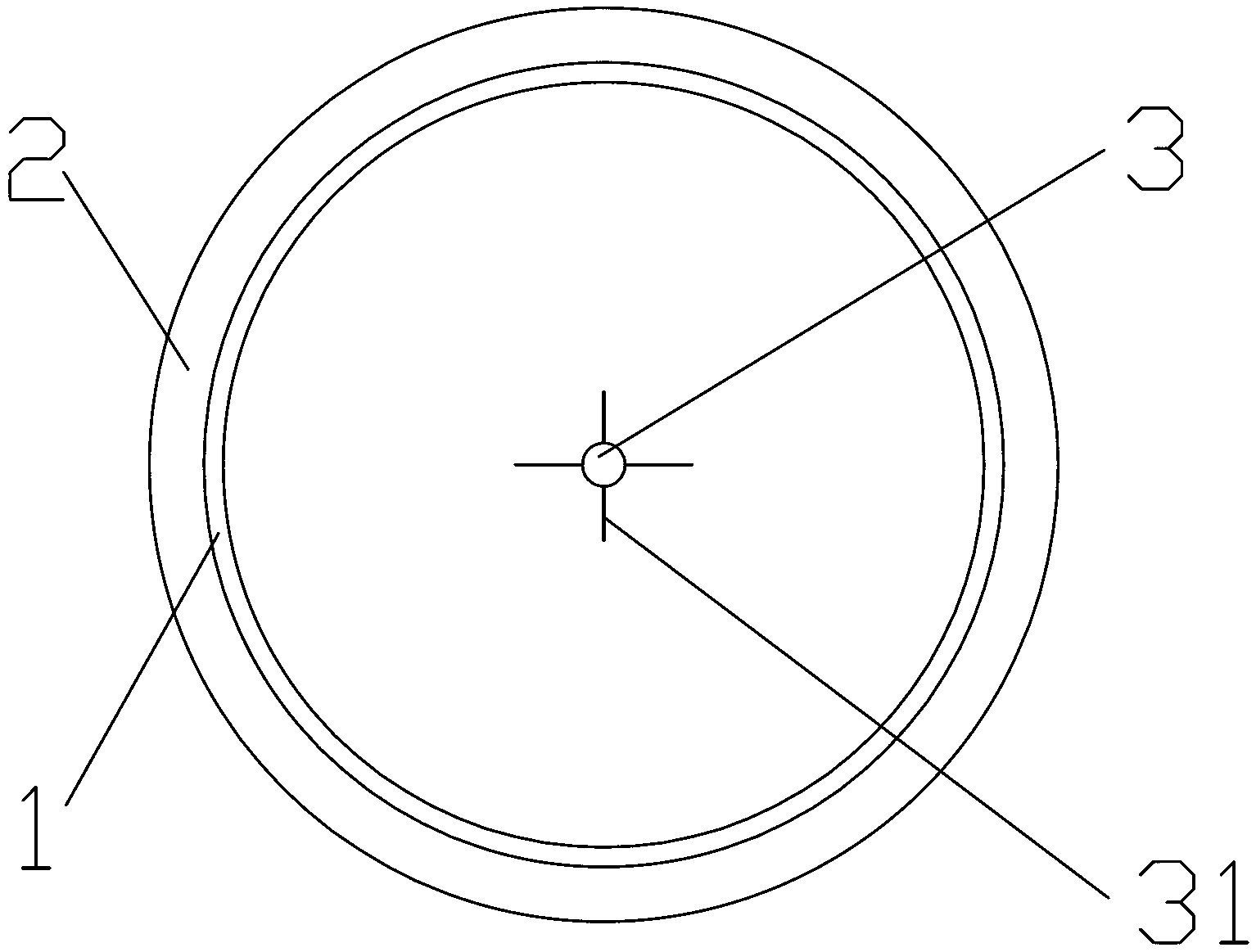

[0020] Embodiment 1, Figure 1~Figure 2 Provided is a filtering composite plasma catalytic treatment diesel engine PM reactor and method, which mainly includes a soot particle trap and a soot particle processing device, and the soot particle processing device includes an anode device and a cathode device.

[0021] The soot particulate trap is a filter cloth bag 1, which is provided with an air inlet, and the air inlet and the cavity (that is, the built-in cavity of the filter cloth bag 1) are connected to each other (the air is discharged into the cavity through the air inlet). Diesel engine exhaust or other exhaust gas containing soot particles that need to be treated); in order to improve the high temperature resistance of the bag, the material used for the filter bag 1 is polytetrafluoroethylene fiber. At the same time, in order to increase the treatment efficiency of diesel engine soot particles, the catalyst TiO2 is loaded on the filter bag 1, and the catalyst TiO2 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com