Patents

Literature

41results about How to "Clean in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

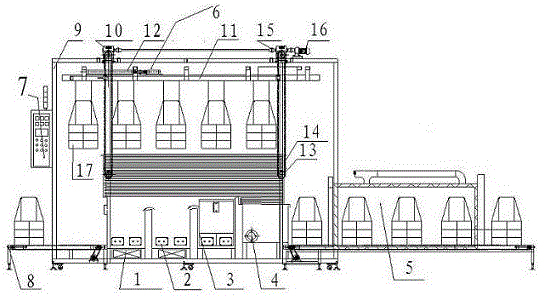

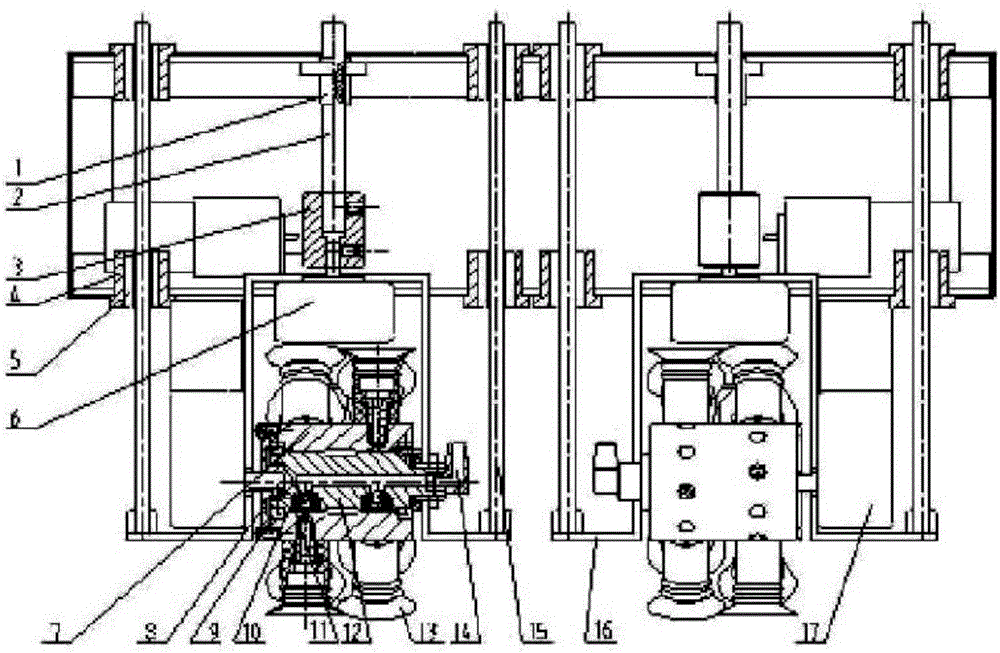

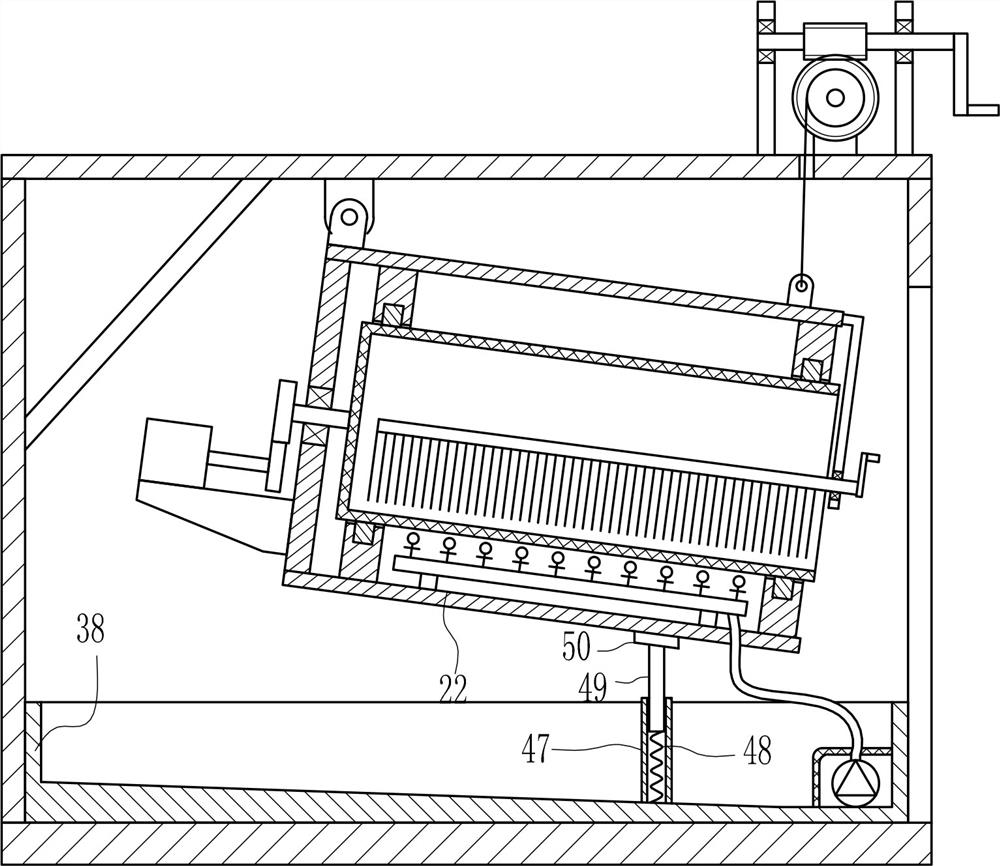

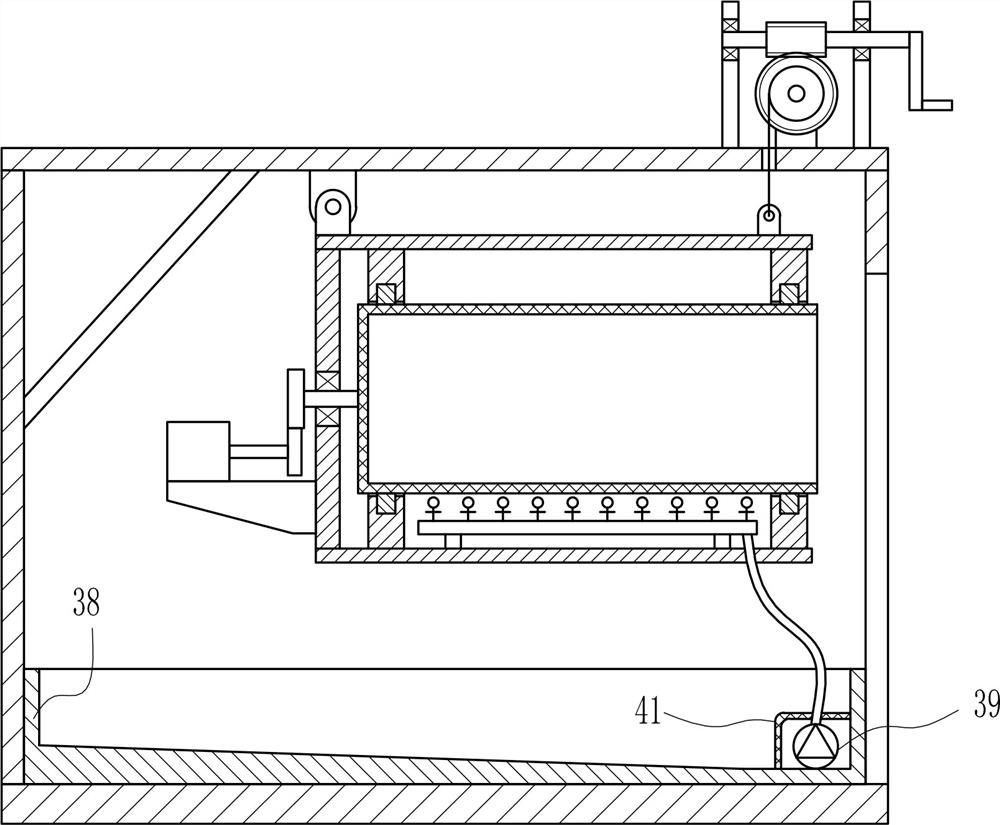

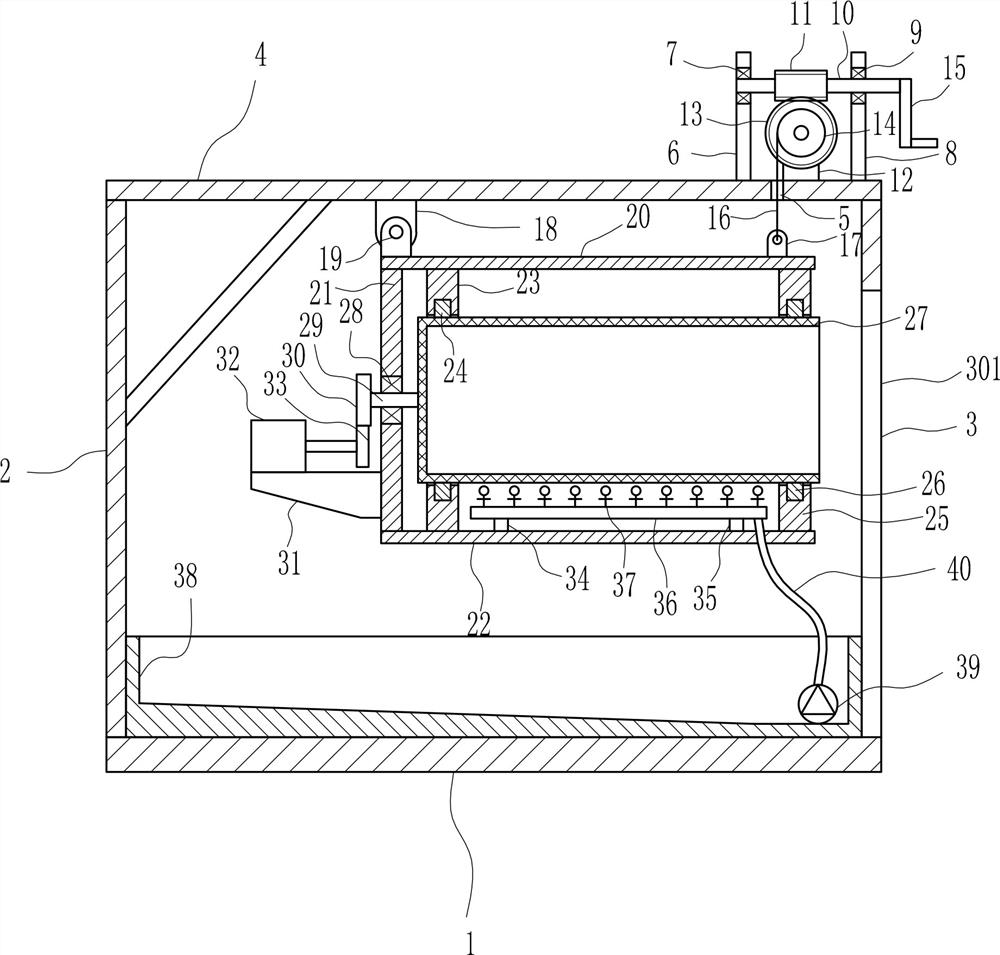

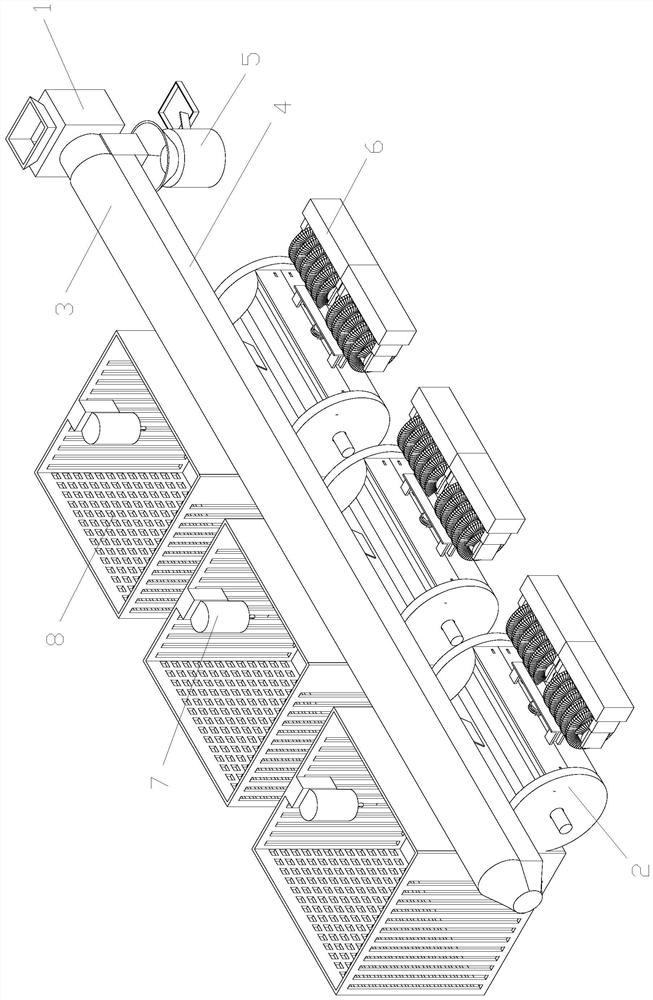

Full-automatic ultrasonic cleaning machine for nickel-based conductor materials

ActiveCN106111618ANot volatileNo wasteDrying gas arrangementsDrying machines with progressive movementsCleansing AgentsContamination

A full-automatic ultrasonic cleaning machine for nickel-based conductor materials is of a closed structure and comprises first ultrasonic rough cleaning tanks, second ultrasonic cleaning tanks, a heat soaking rinse tank, a steam bath wash tank, a hot air internal circulation tunnel type drying box, an automatic portal lifting and travelling mechanism and an electrical control system. According to the full-automatic ultrasonic cleaning machine for the nickel-based conductor materials, automatic all-round cleaning can be conducted, a net bag containing nickel pieces does not need to be rolled over manually, and cleaning can be conducted in place. Besides automatic cleaning, an automatic drying function can also be achieved, original manual airing is omitted, and the nickel pieces are prevented from secondary contamination. Further, an active carbon adsorption device is arranged at an air outlet of the cleaning machine, residual volatile cleaning agents brought out during drying can be effectively adsorbed, and the cleaning agent is prevented from contaminating the air.

Owner:JIANGSU K TECH PRECISION TECH +1

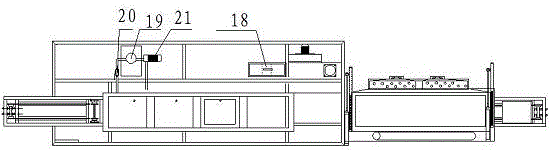

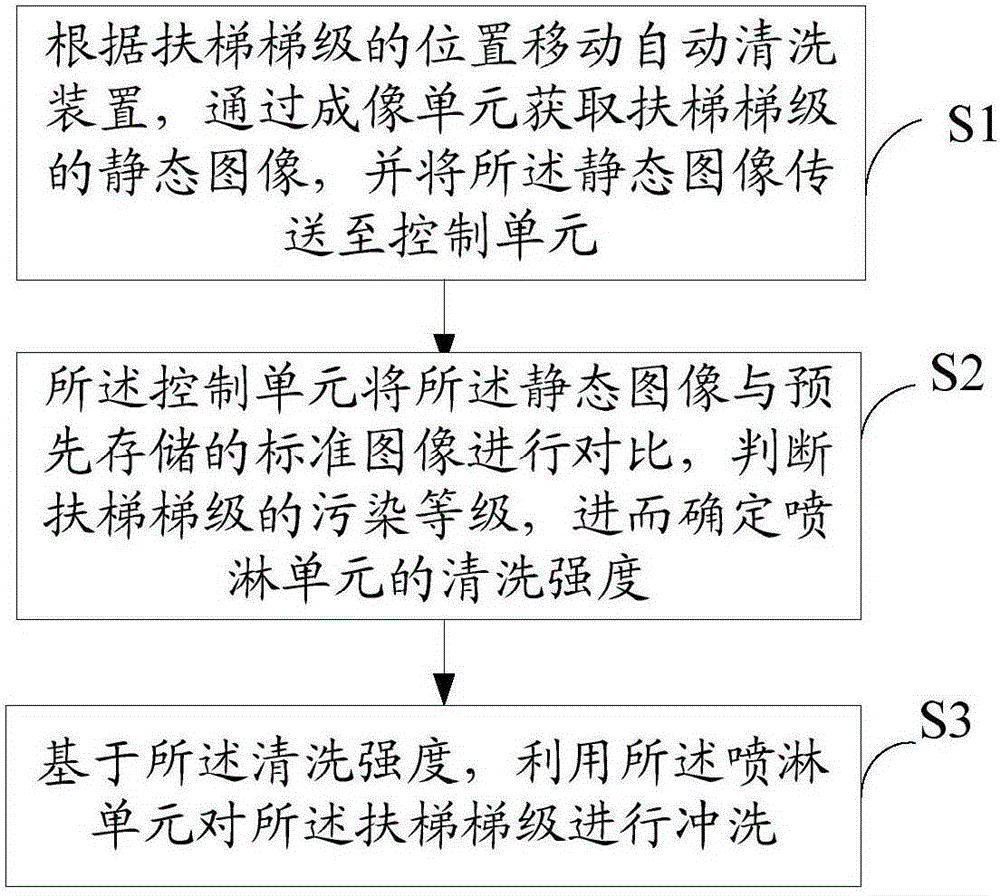

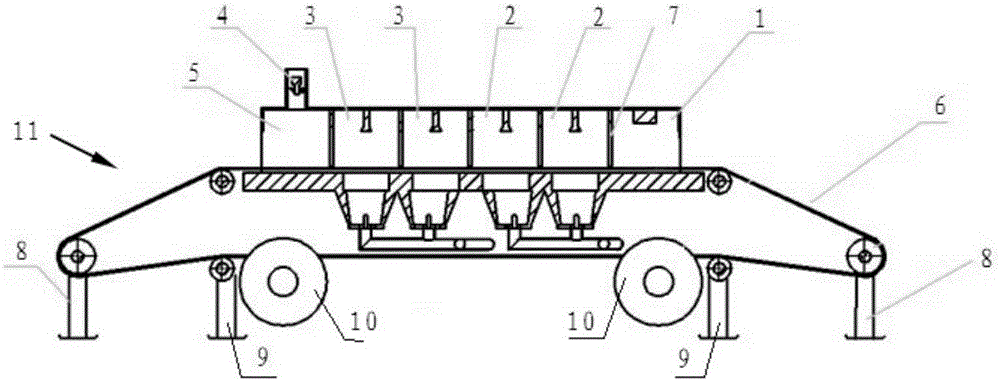

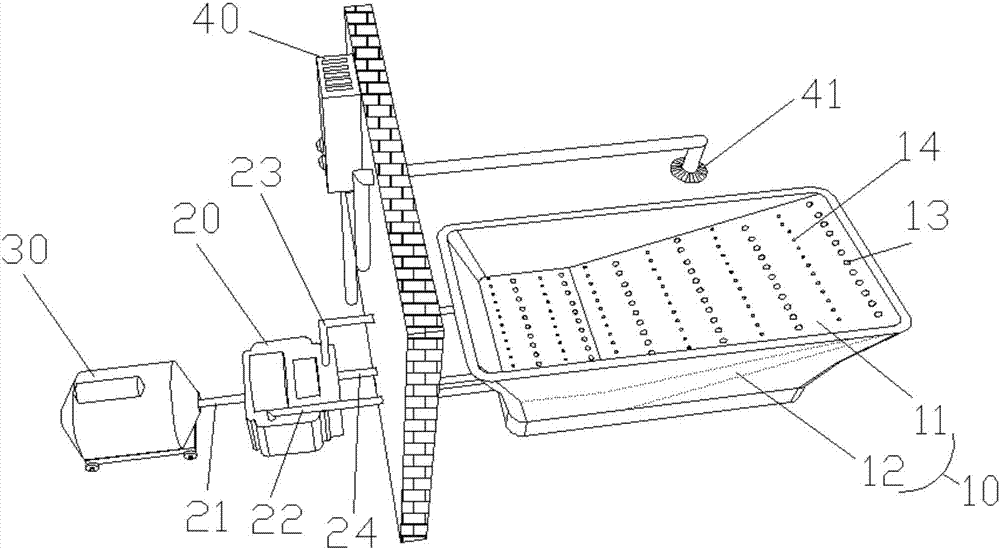

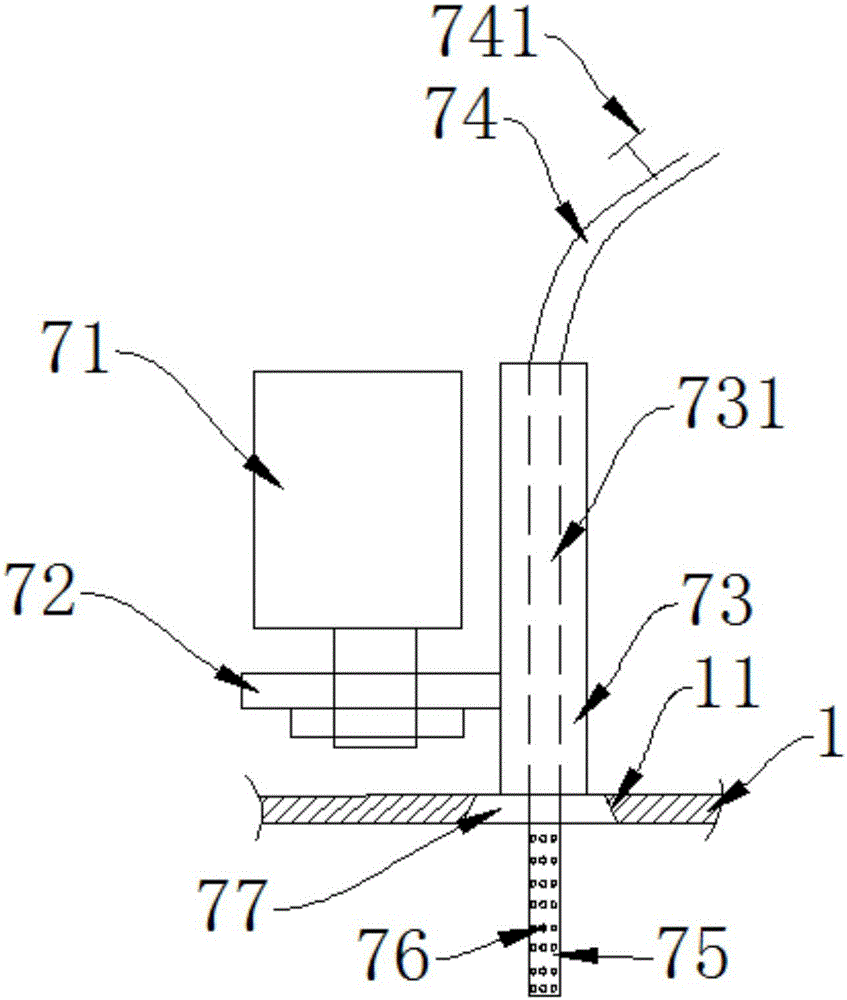

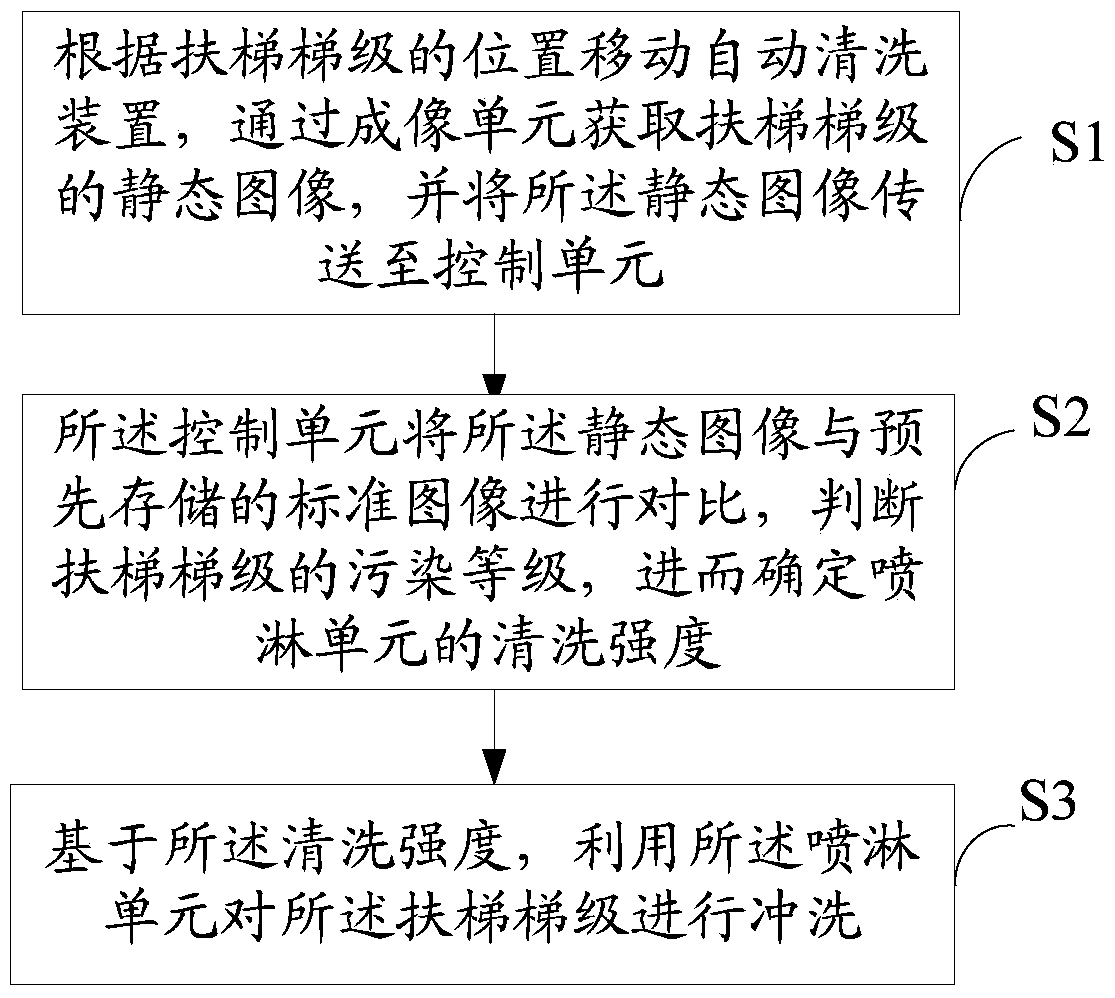

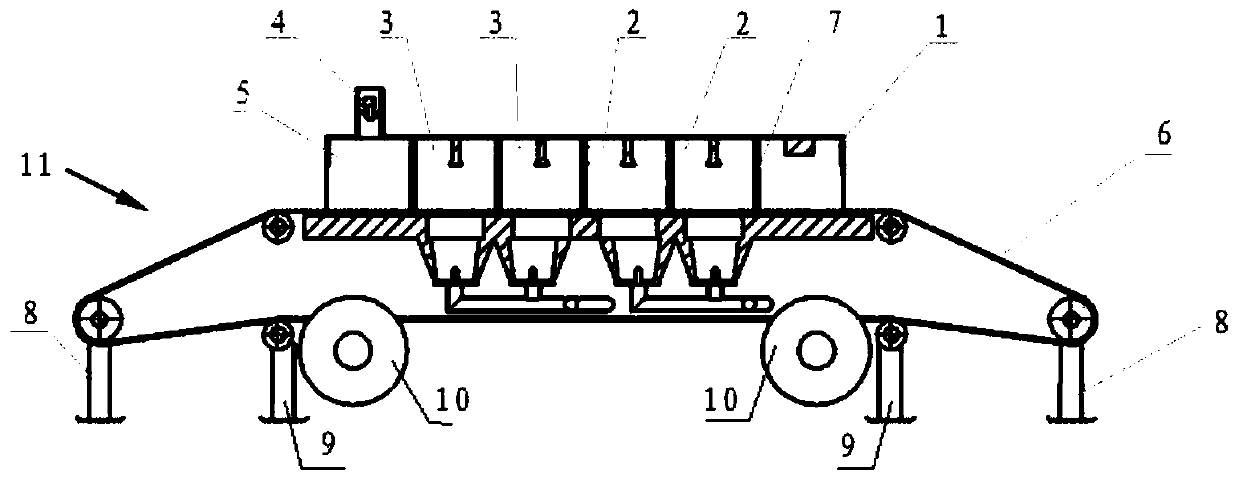

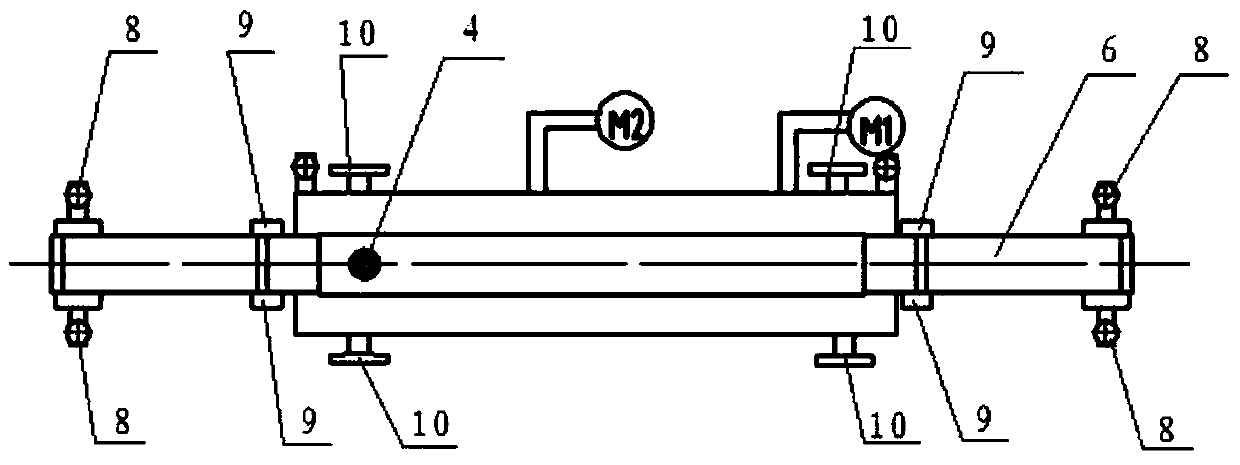

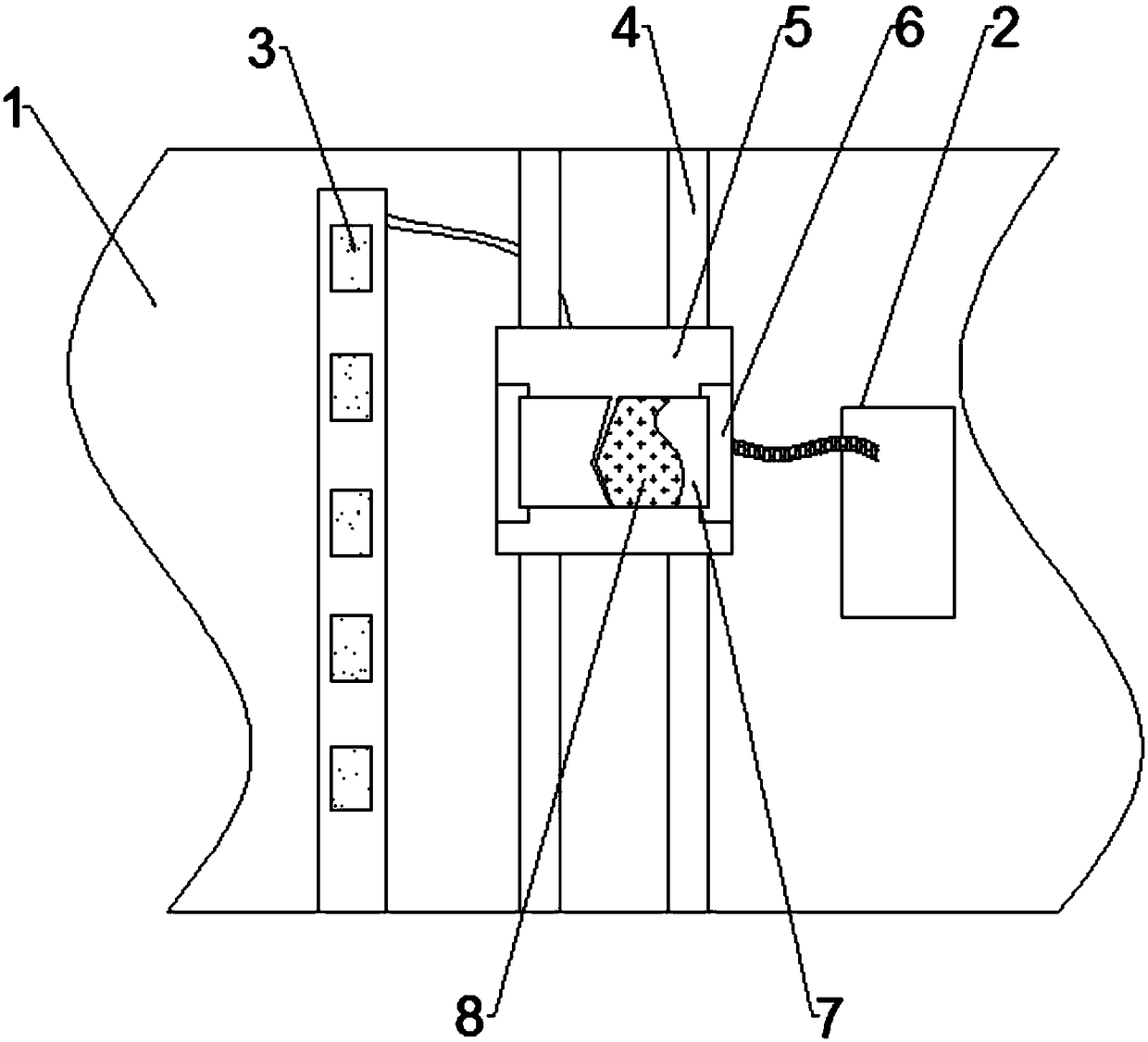

Automatic cleaning method and device for movable escalator steps

ActiveCN105170528AImprove convenienceImprove cleaning efficiencyCleaning using liquidsEscalatorsEngineeringPollution

The invention discloses an automatic cleaning method and device for movable escalator steps. The automatic cleaning method includes the steps that static images of the escalator steps are obtained through an imaging unit and transmitted to a control unit; the control unit compares the static images with pre-stored standard images to judge the pollution grades of the escalator steps and then determine the cleaning intensity in a spraying unit; and based on the cleaning intensity, the escalator steps are cleaned through the spraying unit. By means of the automatic cleaning method and device, the escalator steps can be cleaned in place, the cleaning efficiency is greatly improved, the water consumption of escalator step cleaning is reduced, and negative influences of drained waste water on the environment are avoided.

Owner:BEIJING JIEYUTONG ENVIRONMENTAL PROTECTION SCI & TECH

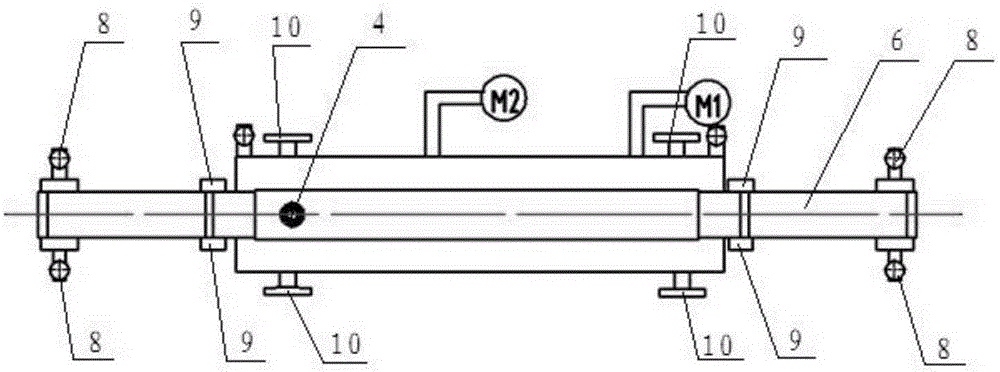

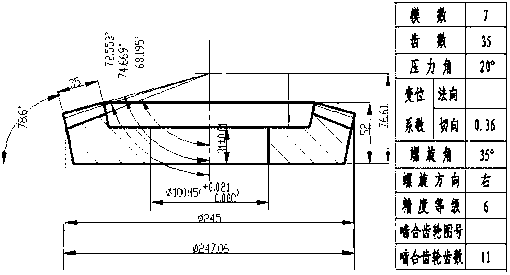

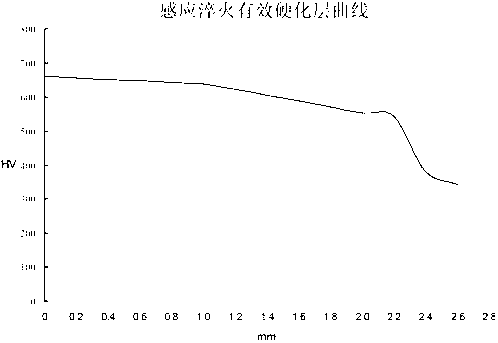

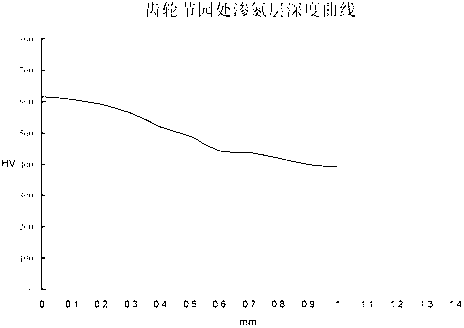

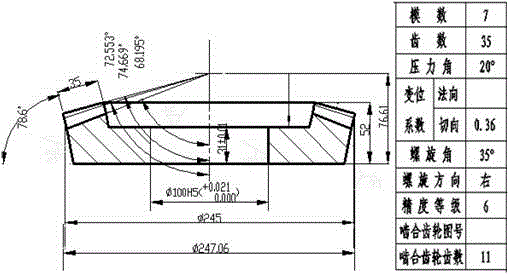

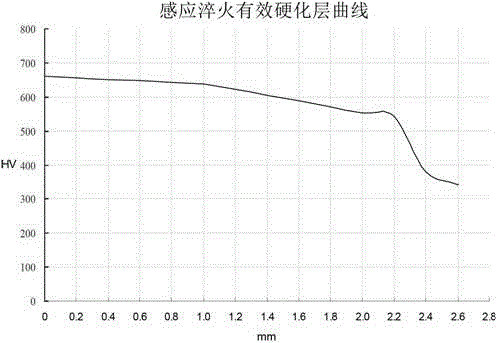

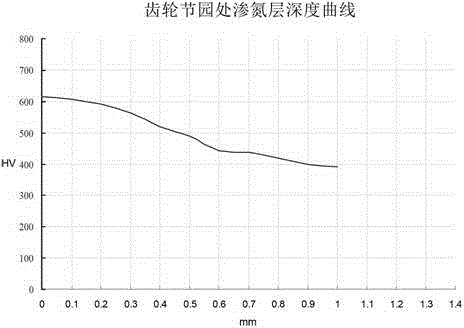

Anti-fatigue manufacturing method of spiral bevel gear

The invention relates to a novel composite surface-enhanced spiral bevel gear production process system based on a current anti-fatigue manufacturing method system and integrating induction quenching and gas nitriding. The invention aims to provide a composite surface-enhanced cyclo-palloid spiral bevel gear manufacturing method with heated precision of 4 to 6 levels and achieving the purpose that the theory contact zone meshed strength is meshed with carburizing and quenching strength. The invention aims to further provide a new spiral bevel gear production technology which can not only embody the current anti-fatigue high-end gear manufacturing method purpose, but also agree with the complete software and hardware match of a roadmap of heat treatment technology development in China.

Owner:天津市天瑞硬化工程有限公司

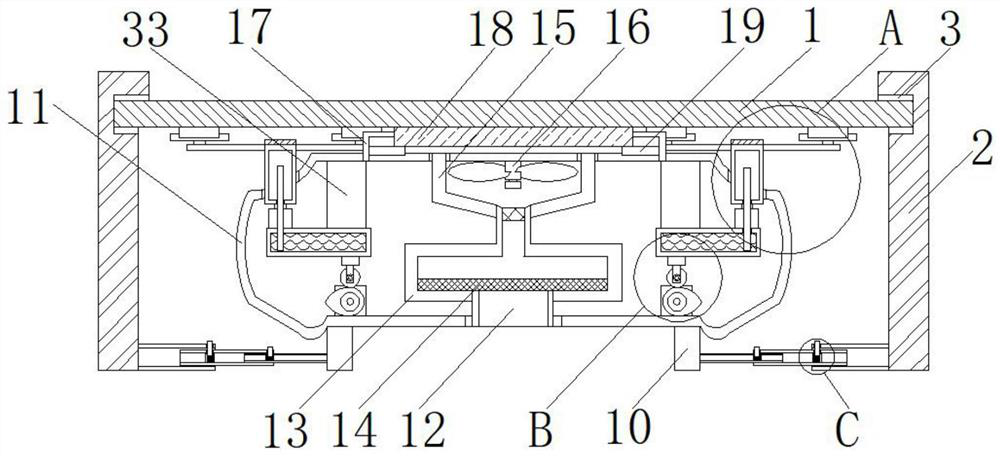

Impeller type dish washing machine and control method thereof

InactiveCN104042172AShorten cleaning timeImprove efficiencyTableware washing/rinsing machine detailsImpellerEngineering

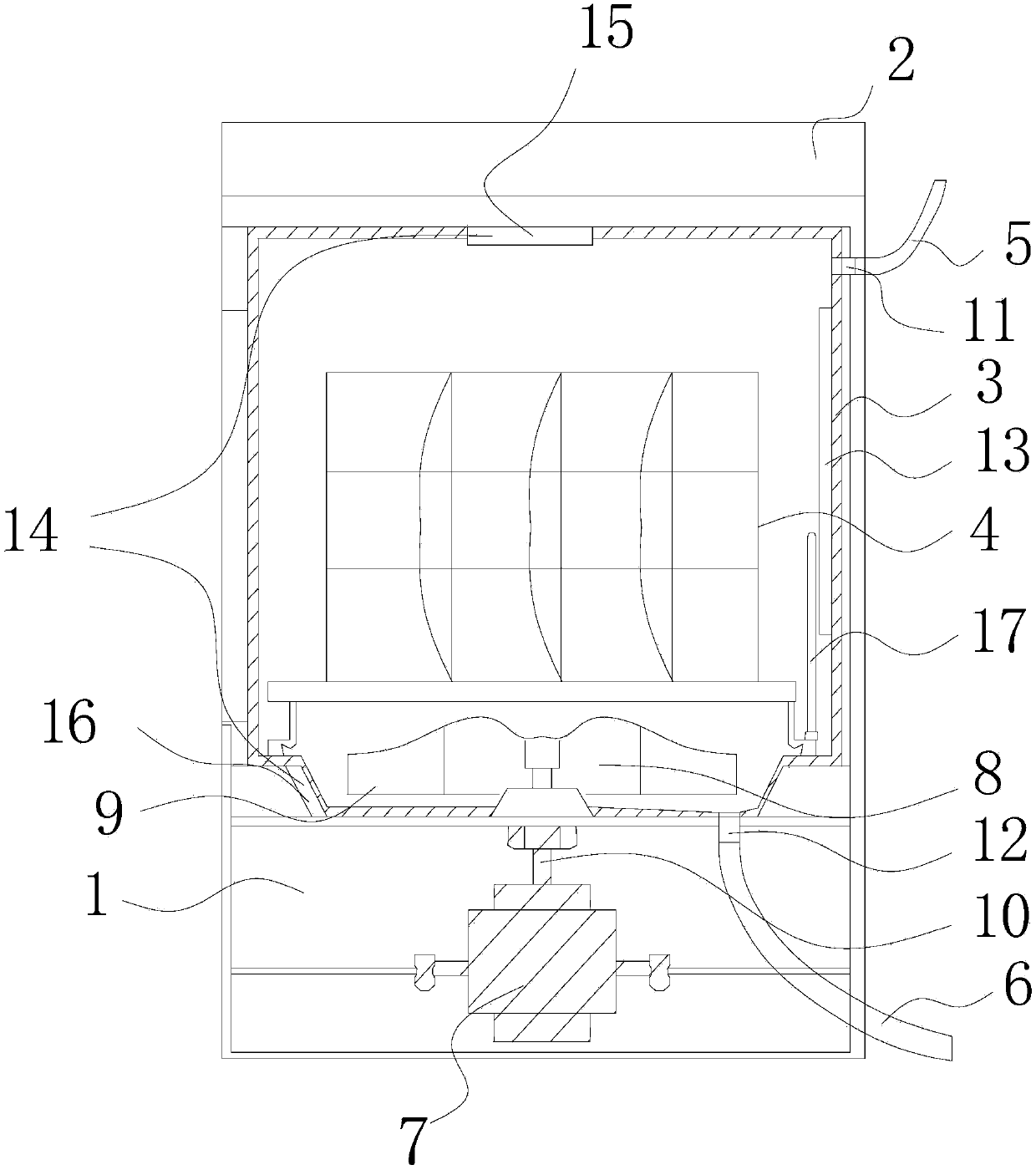

The invention discloses an impeller type dish washing machine and a control method thereof. The impeller type dish washing machine comprises a tank body. The upper portion of the tank body is provided with a control device. A washing cavity is formed in the tank body. A dish basket is installed on the washing cavity. The upper portion and the lower portion of the washing cavity are correspondingly provided with a water inlet pipe and a water outlet pipe, wherein the water inlet pipe and the water outlet pipe extend out of the tank body. The bottom in the tank body is provided with a motor. The bottom of the washing cavity is provided with a rotating shaft. The two ends of the rotating shaft are respectively provided with an impeller. The angle range of the impellers and the rotating shaft is from 10 degrees to 80 degrees; the rotating shaft is connected with a power shaft of the motor through a coupler, and the motor is connected with the control device. The invention further provides the control method for the impeller type dish washing machine. The washing machine has the advantages of washing dishes completely, high in efficiency, easy and convenient to operate, reasonable in price and the like.

Owner:梧州职业学院

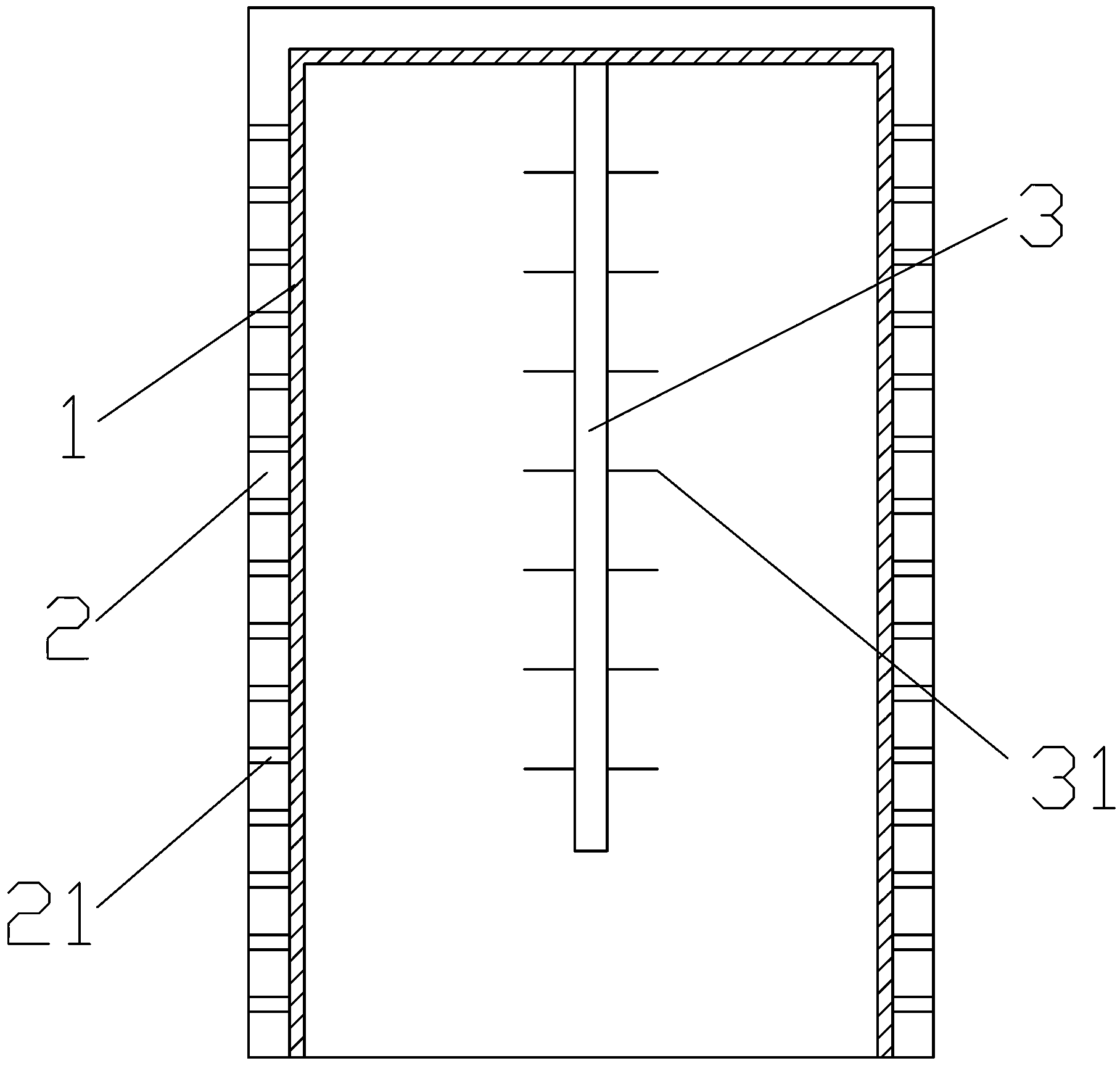

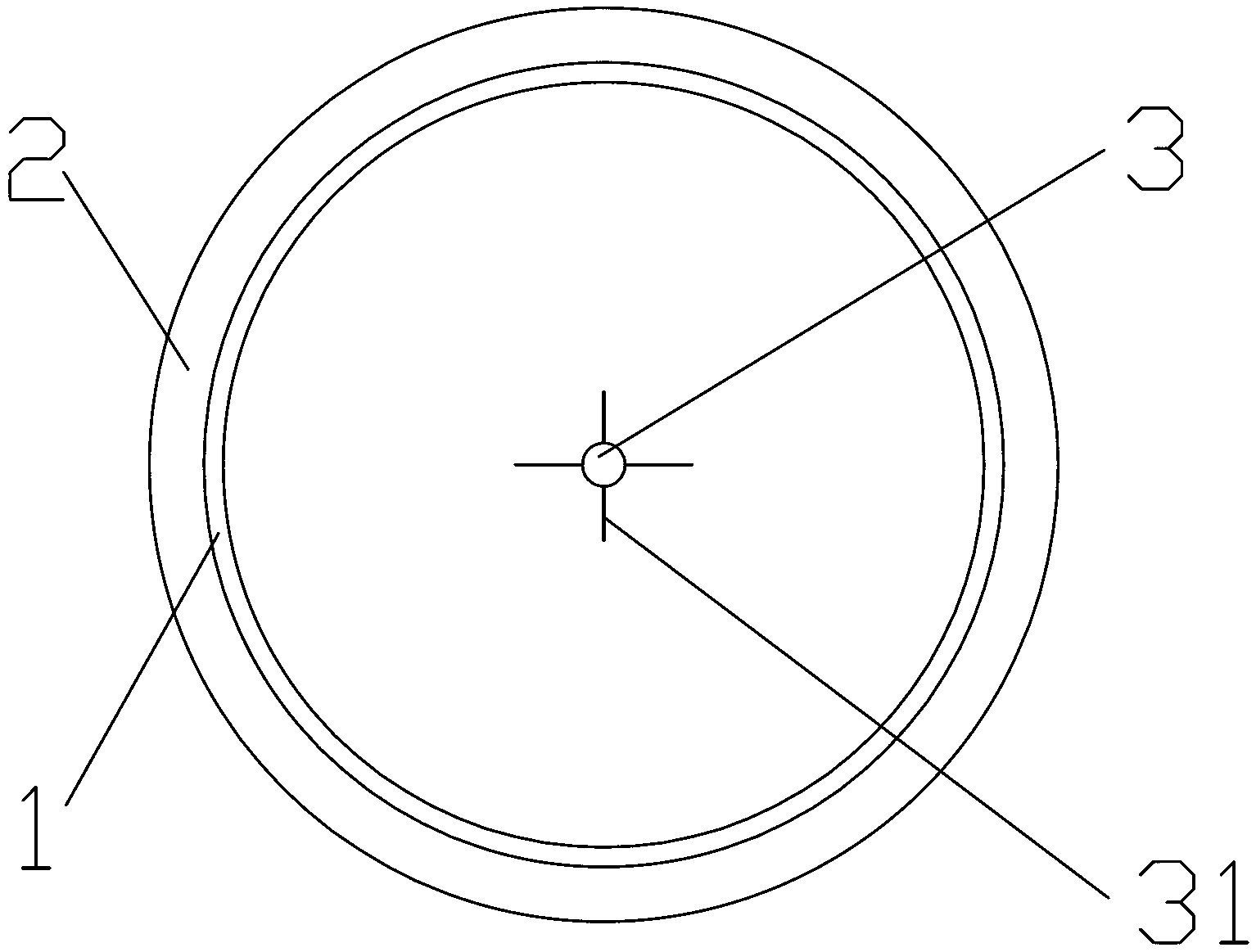

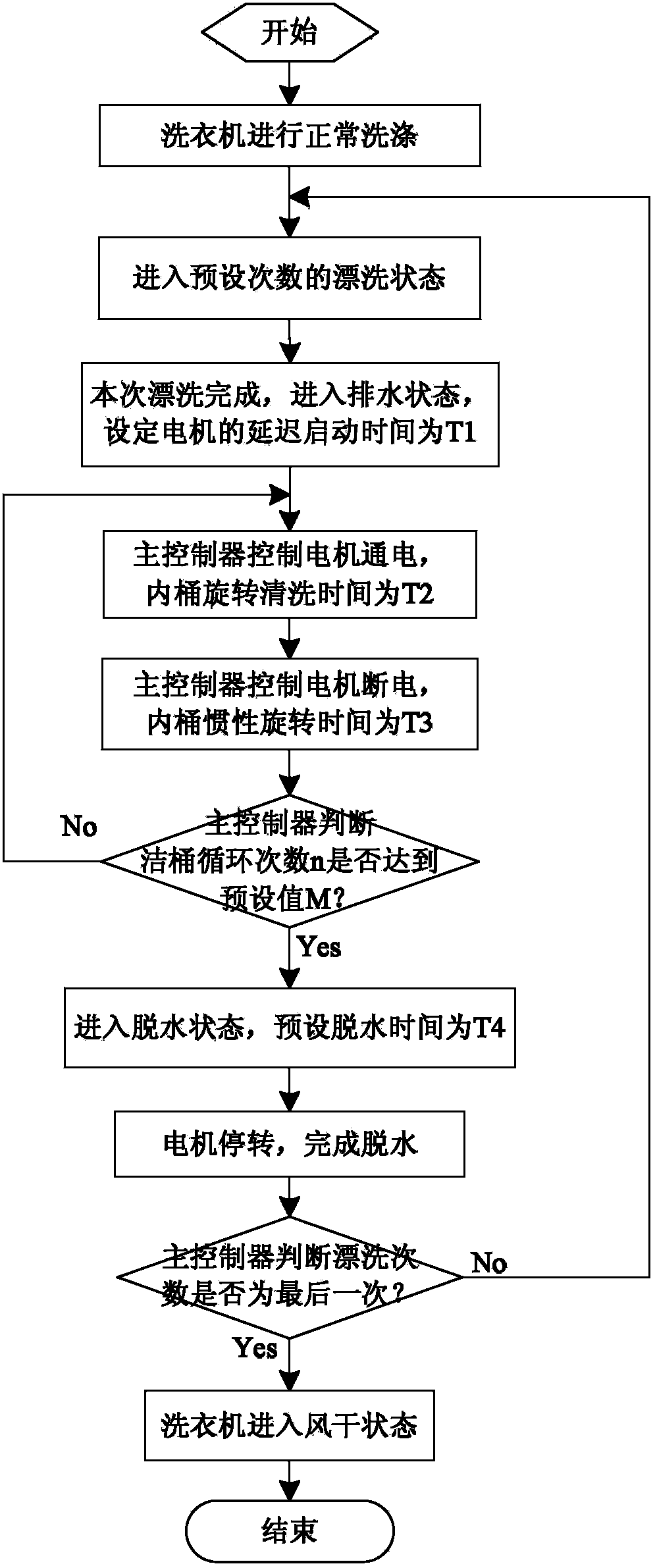

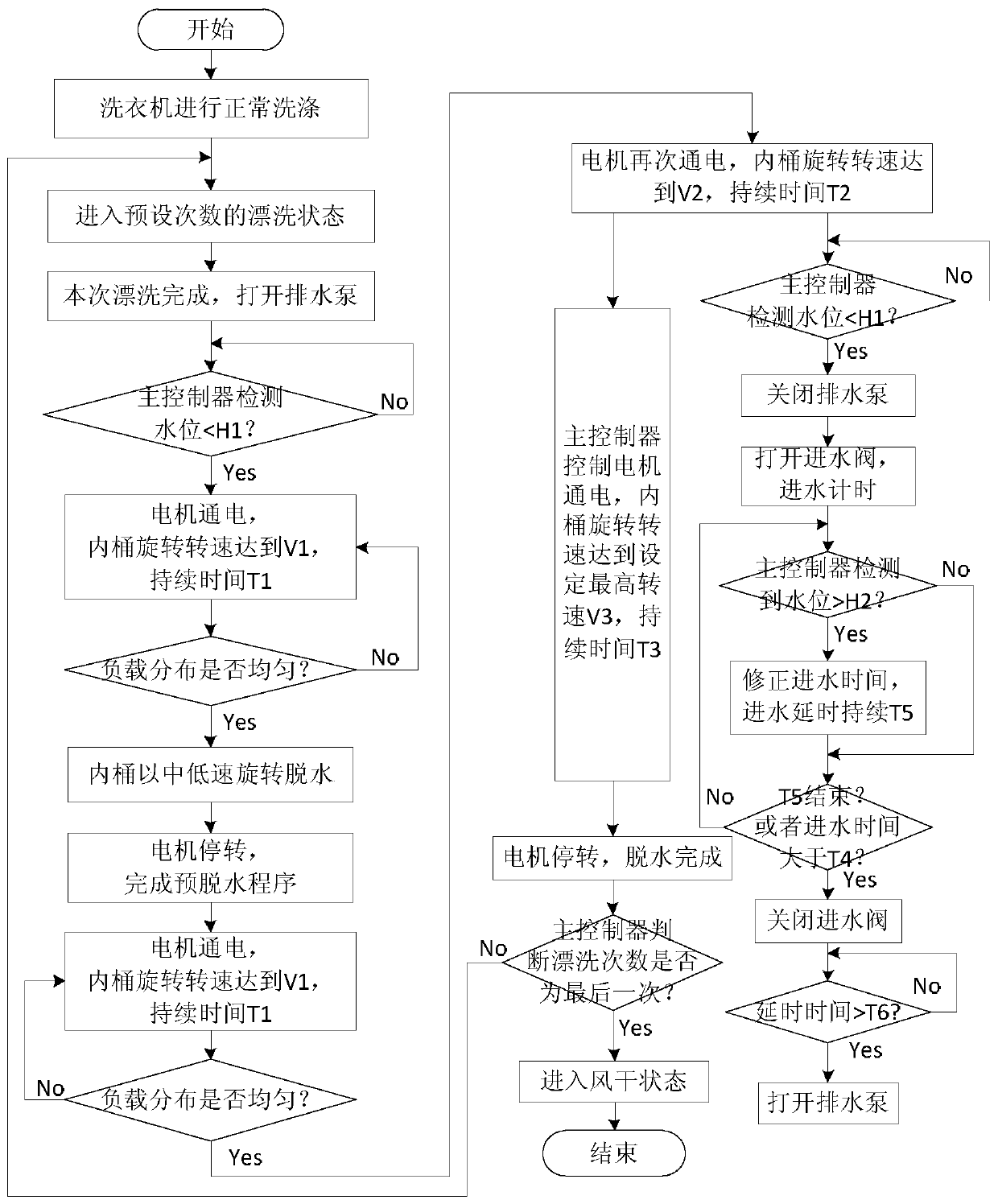

Washing method for washing machine

ActiveCN102776749AEasy to cleanClean in placeOther washing machinesControl devices for washing apparatusStart timeEngineering

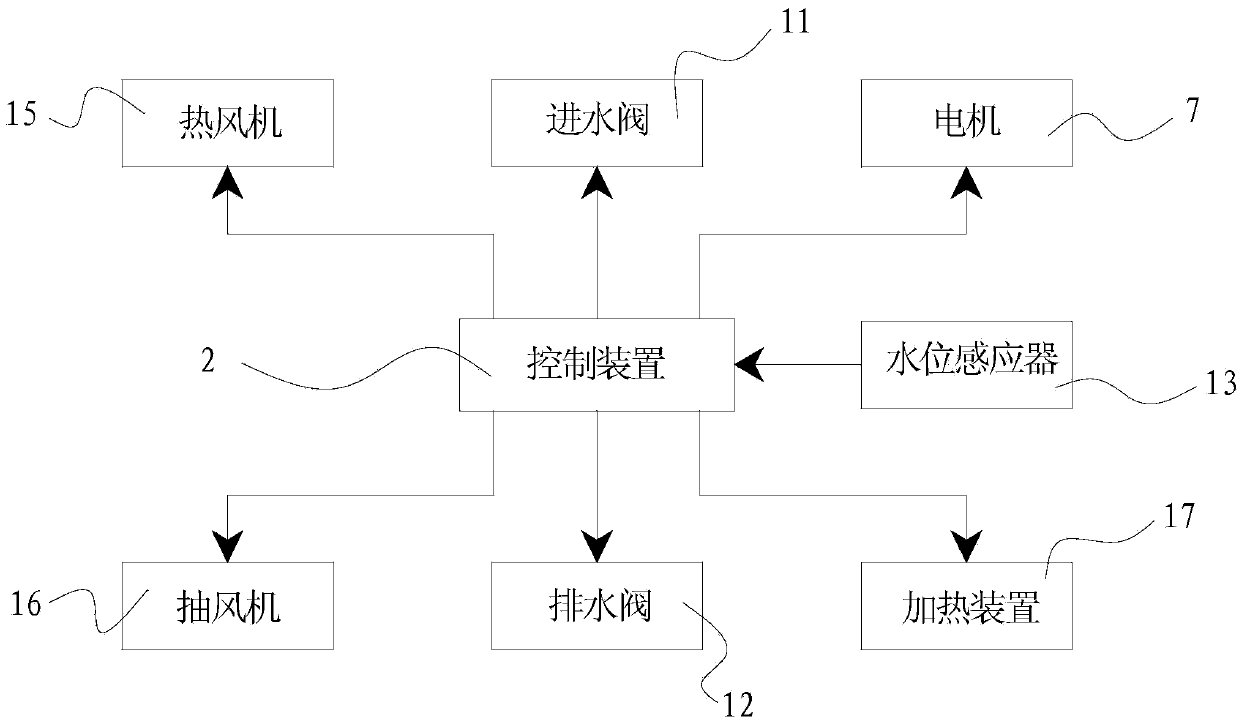

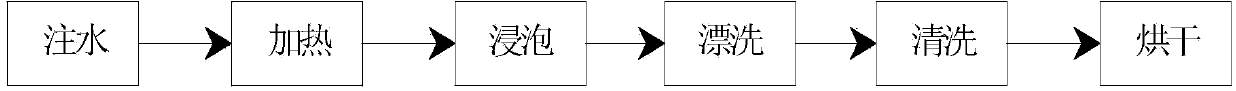

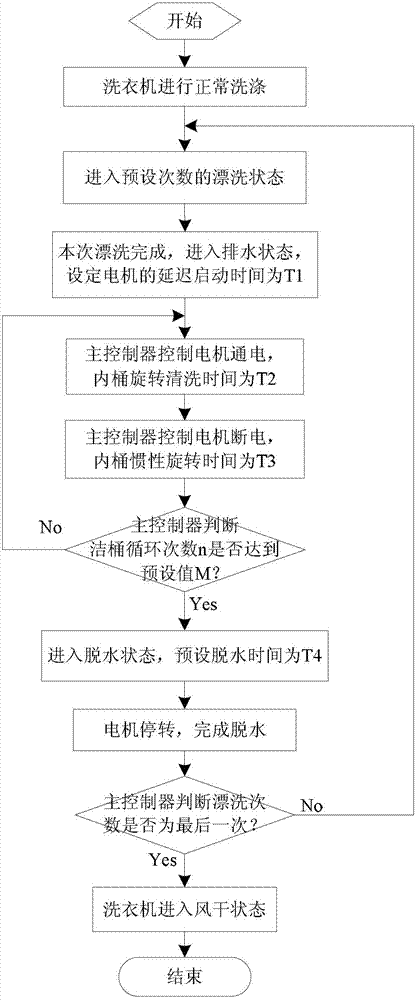

The invention provides a washing method for a washing machine. The washing machine comprises an internal barrel, a motor, a draining valve and a main controller; and the washing method is characterized by comprising the implementation steps as follows: (1) normally washing; (2) rinsing for a plurality of times; (3) completing the rinsing, starting the draining valve to access a draining state, wherein the delay starting time of the motor is T1; (4) electrifying the motor to drive the internal barrel to rotate, wherein the rotary cleaning time is T2; (5) after completing once rotary cleaning, interrupting the power supply of the motor to drive the internal barrel to rotate under inertia, wherein the rotating time under inertia is T3; (6) determining whether the circular cleaning time N of the internal barrel reaches a preset value, if so, entering the next step, if not, returning to step (4); (7) electrifying the motor to enter a dewatering program, wherein the dewatering time is T4; (8) stopping the motor to complete the dewatering, and judging whether the rinsing at the time is the last rinsing, if so, entering the next step, if not, returning to step (2); and (9) drying in the air. According to the washing method, the barrel is cleaned following the rinsing at each time, thus, the washing barrel is repeatedly cleaned for a plurality of times, and the washing barrel can be ensured to be cleaned efficiently.

Owner:NINGBO XINLE HOUSEHOLD APPLIANCES

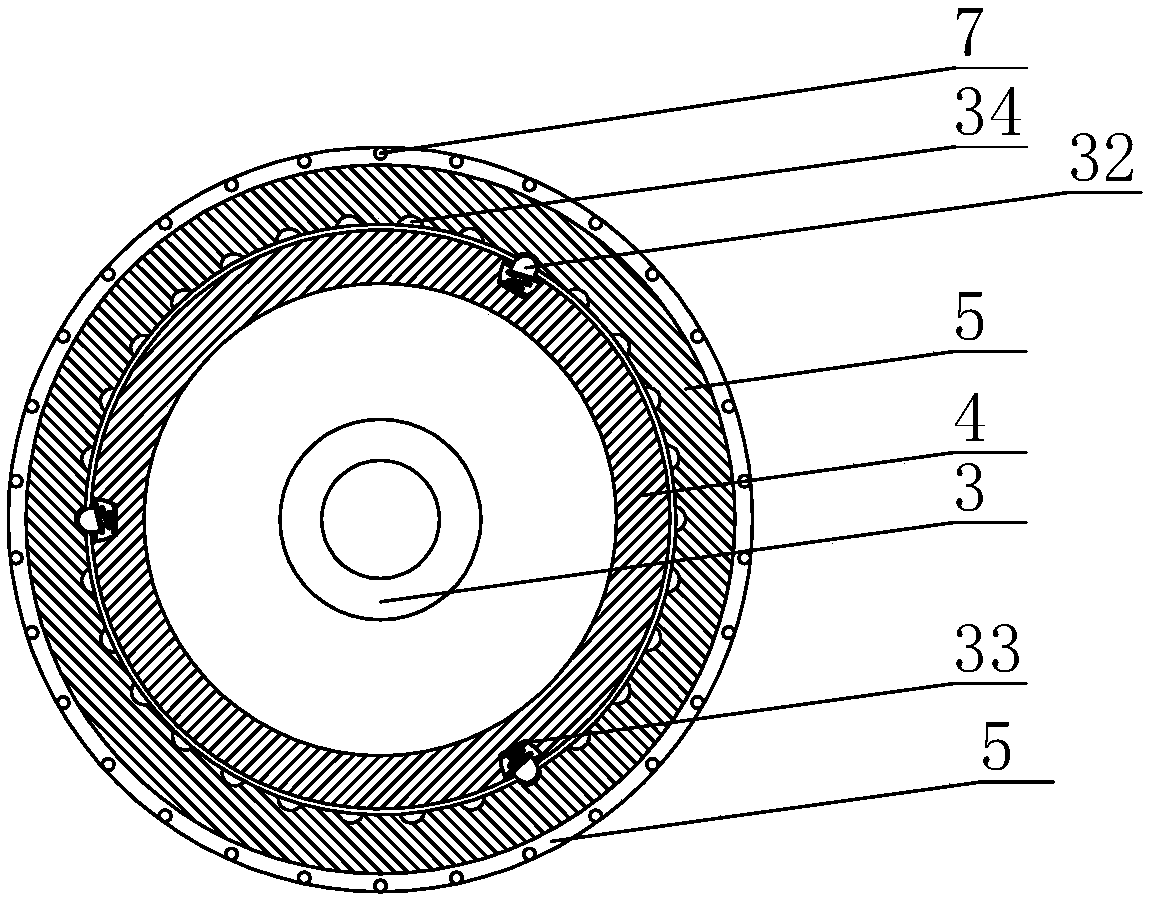

Reactor and method for filtering composite plasma catalytic treatment diesel engine PMs (particulate matters)

InactiveCN103016106AImprove air qualityClean in placeExhaust apparatusSilencing apparatusAnodeDiesel engine

The invention discloses a reactor for filtering composite plasma catalytic treatment diesel engine PMs (particulate matters). The reactor comprises a soot particulate catcher, wherein an air inlet and a cavity are arranged in the soot particulate catcher, the air inlet is communicated with the cavity, a soot particulate treatment device is also arranged on the soot particulate catcher and comprises a cathode device and an anode device, the cathode device is arranged in the cavity, and the anode device is arranged outside the soot particulate catcher in a way of corresponding to the cathode device.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Auto-control wall cleaning apparatus

InactiveCN106618367AEasy to moveClean thoroughlyAutomatic obstacle detectionTravelling automatic controlAutomatic controlDrive motor

The invention discloses an auto-control wall cleaning apparatus, comprising a plurality of cleaning units; each cleaning unit comprises a wheel carrier assembly; a lifting drive motor and a lifting guide structure and lifting structure connected with the lifting drive motor are disposed in each wheel carrier assembly; an adsorbing structure is also disposed in the lower portion of each wheel carrier assembly and comprises a drive motor assembly which is connected with a wheel shaft, the wheel shaft is connected with a hub through a slider, the hub is connected with a suction pipe and a sucker, and the suction pipe is connected to a vacuum pump. The auto-control wall cleaning apparatus is capable of automatically cleaning a glass curtain, can meet the requirement on cleanness, and can provide thorough in-place cleaning for a glass curtain wall.

Owner:YULIN UNIV

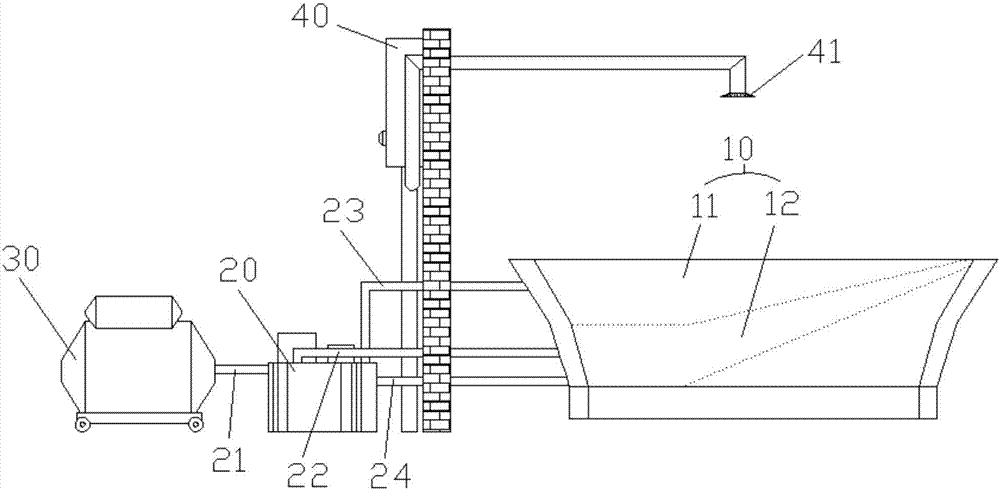

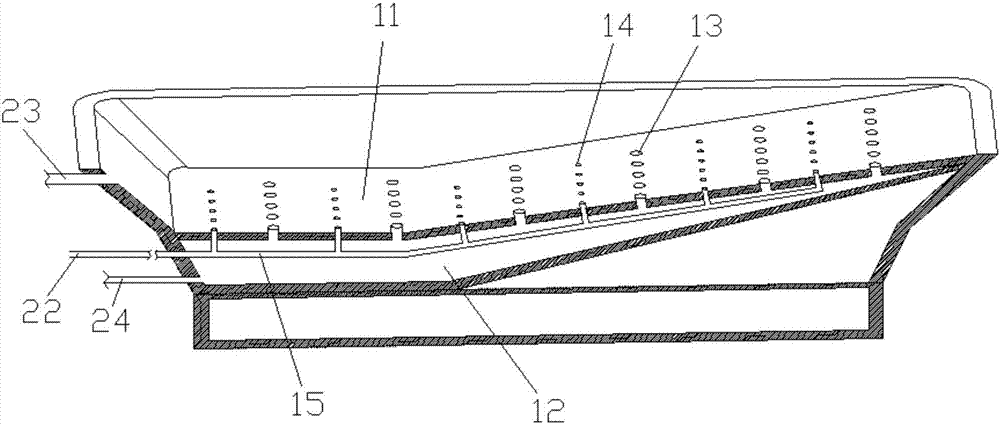

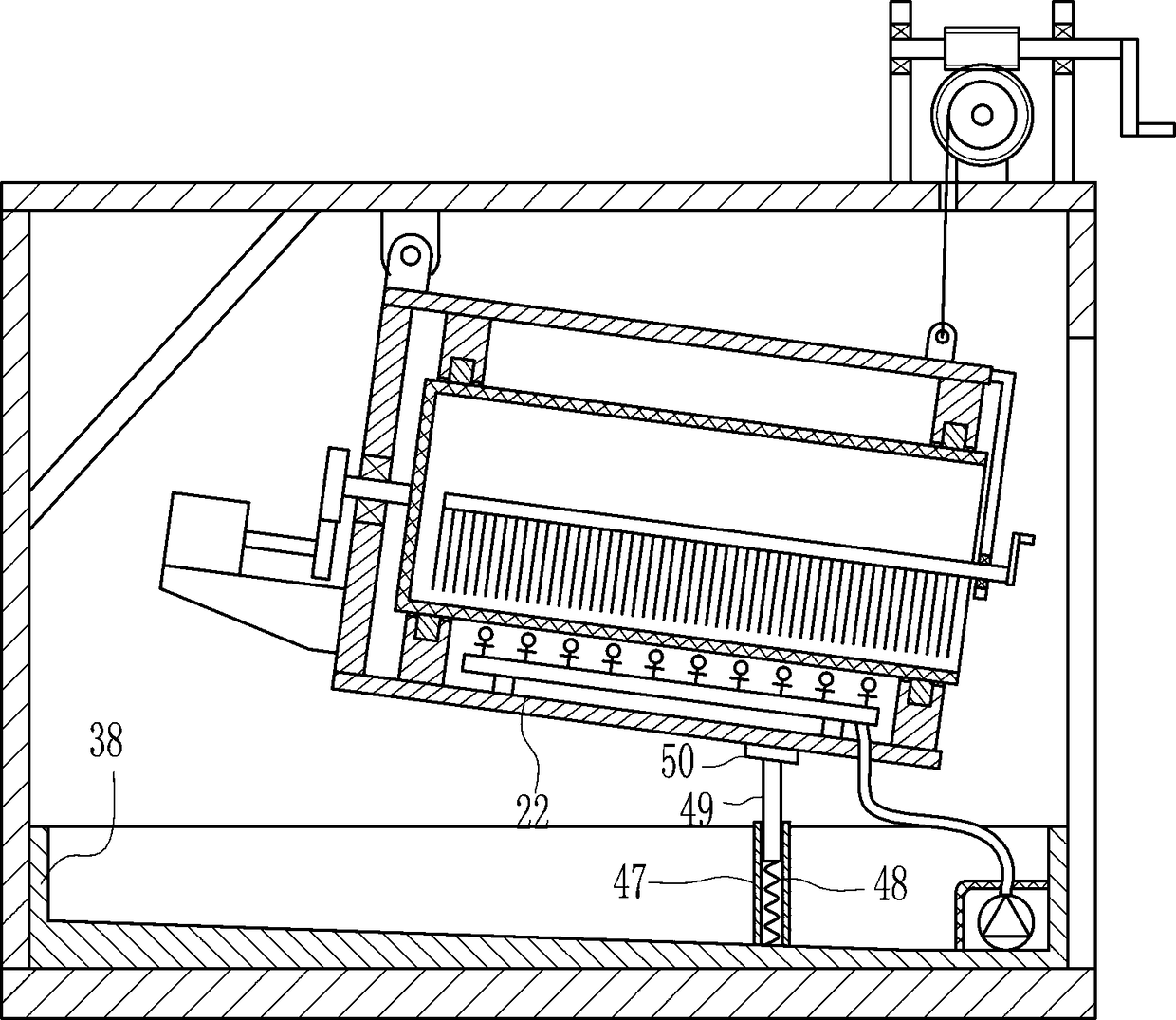

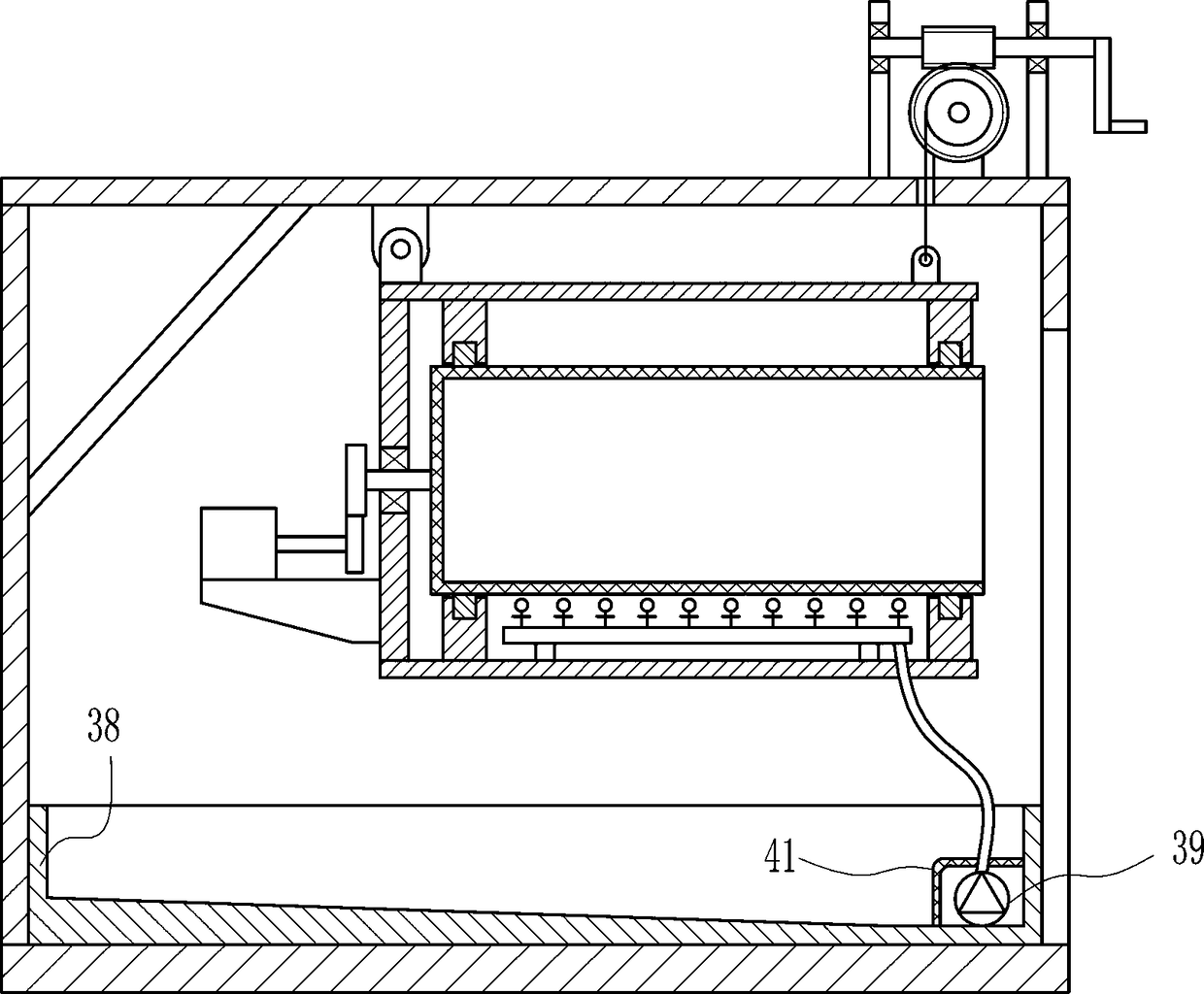

Automatic bathing device

The invention discloses an automatic bathing device. The automatic bathing device comprises a double-layer bathtub, a turbine wheel water pump, an air pump and a water heater, wherein the double-layer bathtub comprises a bathing basin and a return flow chamber adjacent to the bathing basin; a gas inlet pipe of the turbine wheel water pump is connected with the air pump through a pressure relief valve, and a gas outlet pipe of the turbine wheel water pump is connected with branch gas pipes arranged in the return flow chamber; a water inlet pipe of the turbine wheel water pump communicates with the bathing basin, and a water outlet pipe of the turbine wheel water pump communicates with the return flow chamber; water outlet holes and gas outlet holes are formed in a basin wall between the bathing basin and the return flow chamber, the water outlet holes communicate with the bathing basin and the return flow chamber. The turbine wheel water pump consists of a steam turbine and a centrifugal pump, wherein the steam turbine is connected with the centrifugal pump; the air pump comprises a compressed air pump or high-pressure water vapor pump with an air cylinder. The automatic bathing device is driven only by the air pump, circulating water flow and impacting air bubbles can be formed in the bathing basin, and bathing water in the bathing basin can be broken away from dangerous electrical equipment, so that the automatic bathing device is safe and practical.

Owner:袁哲

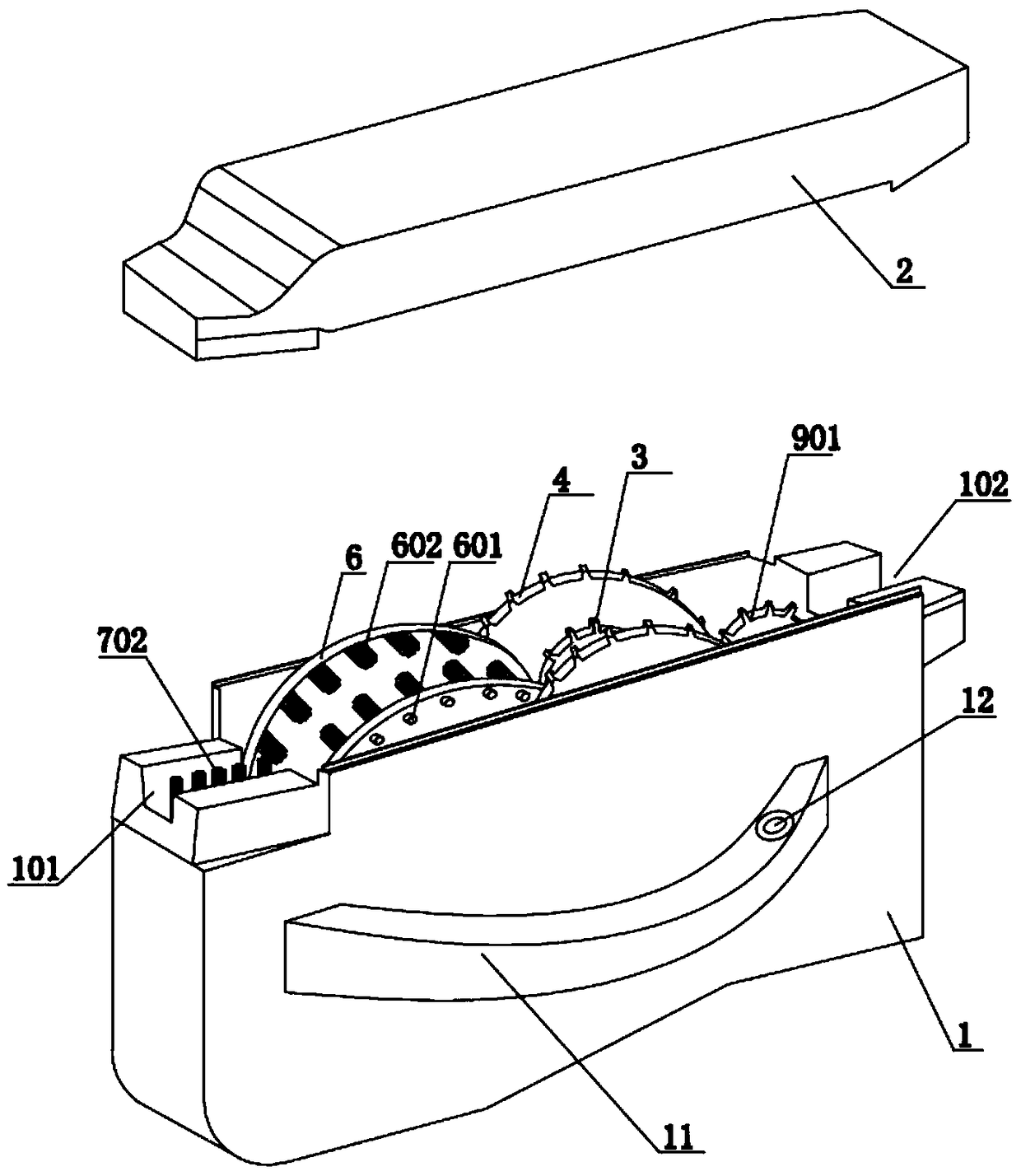

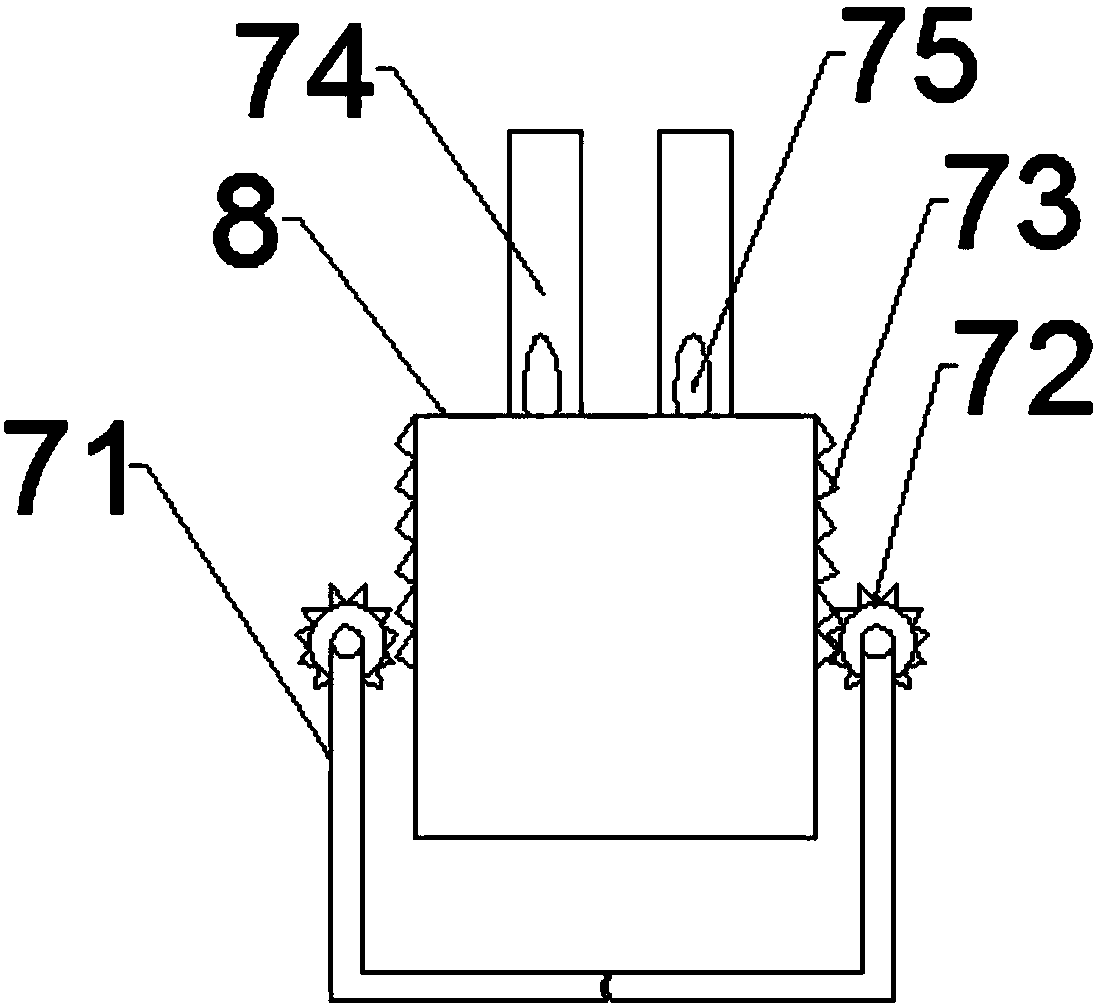

Edible-pupa cleaning equipment

InactiveCN108906718AAchieve cleaning functionAchieve the buffer functionCleaning using toolsCleaning using liquidsEngineeringPupa

The invention relates to cleaning equipment, in particular to edible-pupa cleaning equipment which is complete in cleaning, proper in cleaning force and simple in operation. The technical scheme includes that the edible-pupa cleaning equipment comprises a base, a first support, a second support, a third support, a first fixing plate, a first bearing block, a second fixing plate, a second bearing block, a first rotating shaft and the like; the first support is fixedly connected to the upper left side of the base, the second support is fixedly connected to the upper right side of the base, a through hole is formed in the second support, the third support is fixedly connected to the end of each of the first support and the second support, and a guiding hole is formed in the right side of thethird support. By the arrangement, the function of edible-pupa cleaning is achieved, water is filtered, manual cleaning is substituted, and the edible-pupa cleaning equipment has the advantages of simpleness in operation, proper cleaning and appropriate cleaning force and the like.

Owner:南京幸庄科技创新产业园管理有限公司

Telescopic long gun 3D tank washing device

InactiveCN106994456AClean in placeHealth and Safety Standard GuaranteeHollow article cleaningEngineeringTank container

The invention discloses a telescopic long gun 3D tank washing device. The telescopic long gun 3D tank washing device comprises a cleaning head, a rotation driver used for driving the cleaning head to rotate, and a linear driver used for driving the cleaning head to move in the linear direction. According to the telescopic long gun 3D tank washing device, the rotation driver drives the cleaning head to rotate, and the linear driver drives the cleaning head to extend and retract in the linear length direction, so that the cleaning head can clean a tank at 360 degrees in all directions, cleaning of a tool body and a tank container is guaranteed more thorough, and the purpose that sanitary safety reaches the standard is guaranteed.

Owner:GUANGZHOU FUSEN ENVIRONMENTAL PROTECTION TECH CO LTD

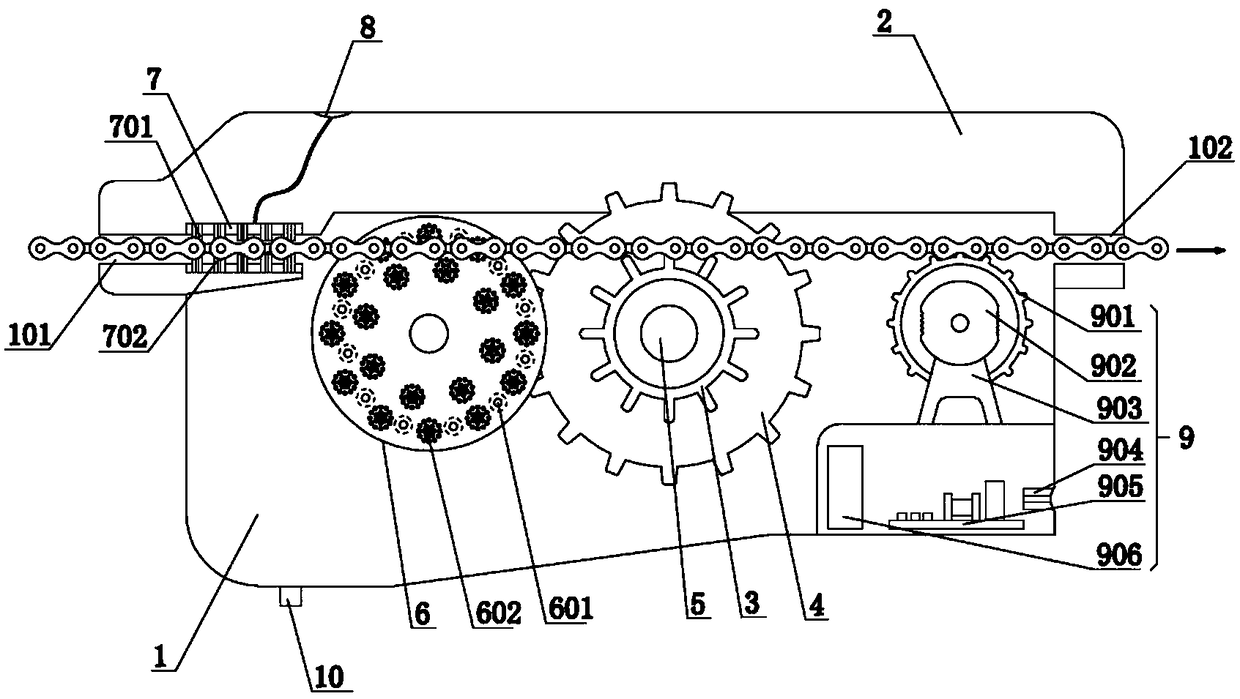

Automatic device for cleaning chain

InactiveCN109225970AImprove efficiencyReduce manual processCleaning using toolsAutomatic transmissionSlag

Owner:袁煜

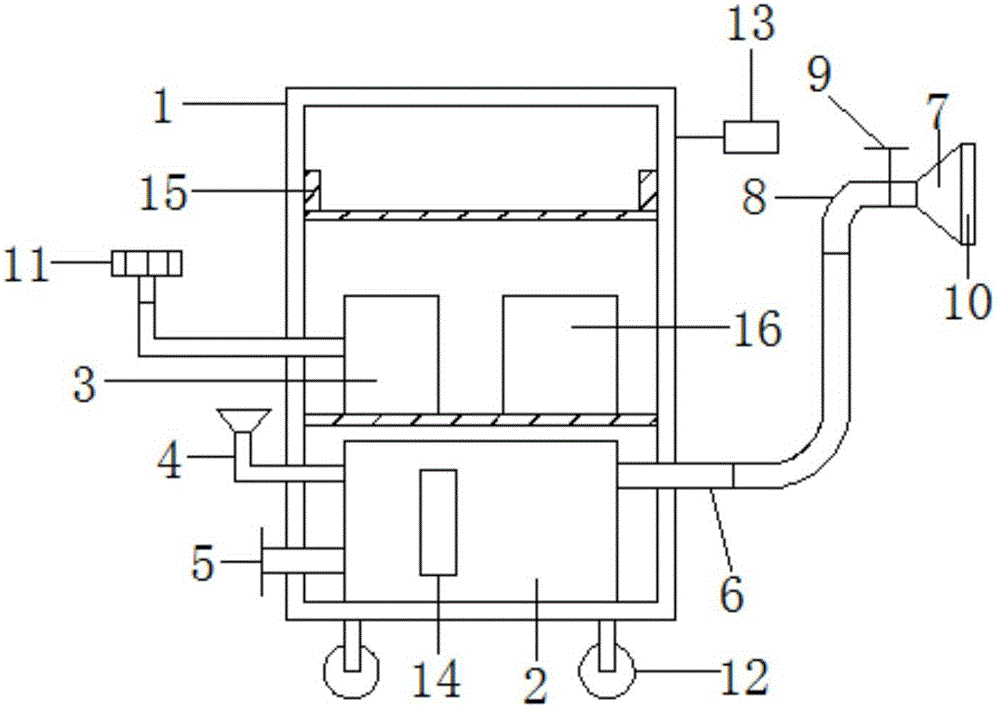

Car cleaner

InactiveCN106143427AExtended service lifeReduce usageVehicle drying apparatusCleaning apparatus for vehicle interiorsEngineeringCleansing Agents

The invention relates to the technical field of car cleaner, in particular to a car cleaner which comprises a cleaner rack. A water box and an air blower are mounted on the cleaner rack; the water box is provided with a cleaning agent inlet, a water inlet and a water outlet; the water outlet is connected with a nozzle through a water outlet pipe, an elbow is connected between the water outlet pipe and the nozzle, a flow regulating valve is mounted on the nozzle, and cleaning cotton tips are mounted on two sides of the nozzle. The air blower is provided with a brush detachably through the air outlet pipe, and the brush is provided with an air outlet. The cleaner rack is further provided with a handhold dust collector and a mobile power pack. The water outlet pipe is protected effectively through the design of the elbow, so that connection section of the water outlet pipe and the nozzle is protected effectively and service life of the water outlet pipe is prolonged. The cleaning cotton tips mounted on two sides of the nozzle are used for cleaning stubborn stains on car bodies when the car bodies are washed by water, and accordingly cleaning is facilitated and cleaning effect is better.

Owner:扬州莱斯帝汽车装备有限公司

Cleaning device for mixing machine of water purifying agent for aquaculture

InactiveCN106424045AMeet cleaning needsRealize multi-angle cleaningHollow article cleaningCleaning using liquidsWater sprayMechanical engineering

The invention provides a cleaning device for a mixing machine of a water purifying agent for aquaculture, and belongs to the field of auxiliary equipment of mixing machines. The cleaning device comprises a conical cylinder, and a cleaning device arranged at the upper end of the conical cylinder; the cleaning device includes water spraying pipes capable of rotating and lifting; two water spraying pipes are provided, and are uniformly distributed about the center line of the conical cylinder; and multiple water outlet holes are formed in the water spraying pipes. The cleaning device is simple in structure; and when cleaning liquid is sprayed out from the water outlet holes, the rotation and the lifting can be realized, so that the cleaning in multiple angles is realized, and the effect is excellent.

Owner:RIYANG TIANJIN BIOTECH DEV CO LTD

A mobile escalator step automatic cleaning method and device

ActiveCN105170528BImprove convenienceImprove cleaning efficiencyCleaning using liquidsEscalatorsWastewaterEngineering

The invention discloses an automatic cleaning method and device for movable escalator steps. The automatic cleaning method includes the steps that static images of the escalator steps are obtained through an imaging unit and transmitted to a control unit; the control unit compares the static images with pre-stored standard images to judge the pollution grades of the escalator steps and then determine the cleaning intensity in a spraying unit; and based on the cleaning intensity, the escalator steps are cleaned through the spraying unit. By means of the automatic cleaning method and device, the escalator steps can be cleaned in place, the cleaning efficiency is greatly improved, the water consumption of escalator step cleaning is reduced, and negative influences of drained waste water on the environment are avoided.

Owner:BEIJING JIEYUTONG ENVIRONMENTAL PROTECTION SCI & TECH

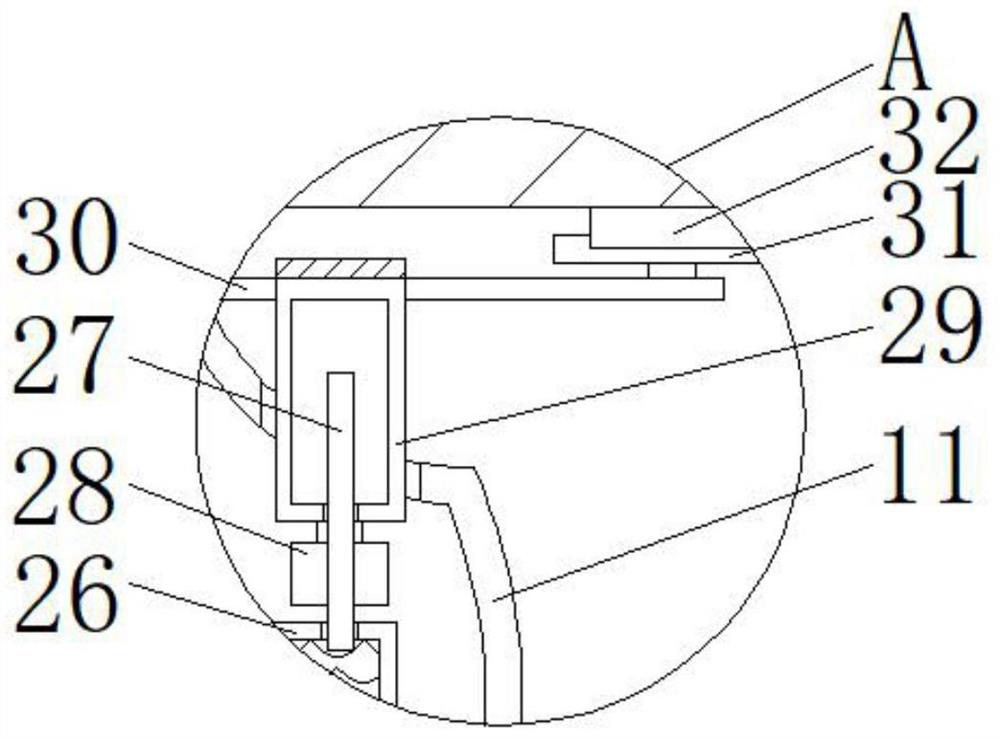

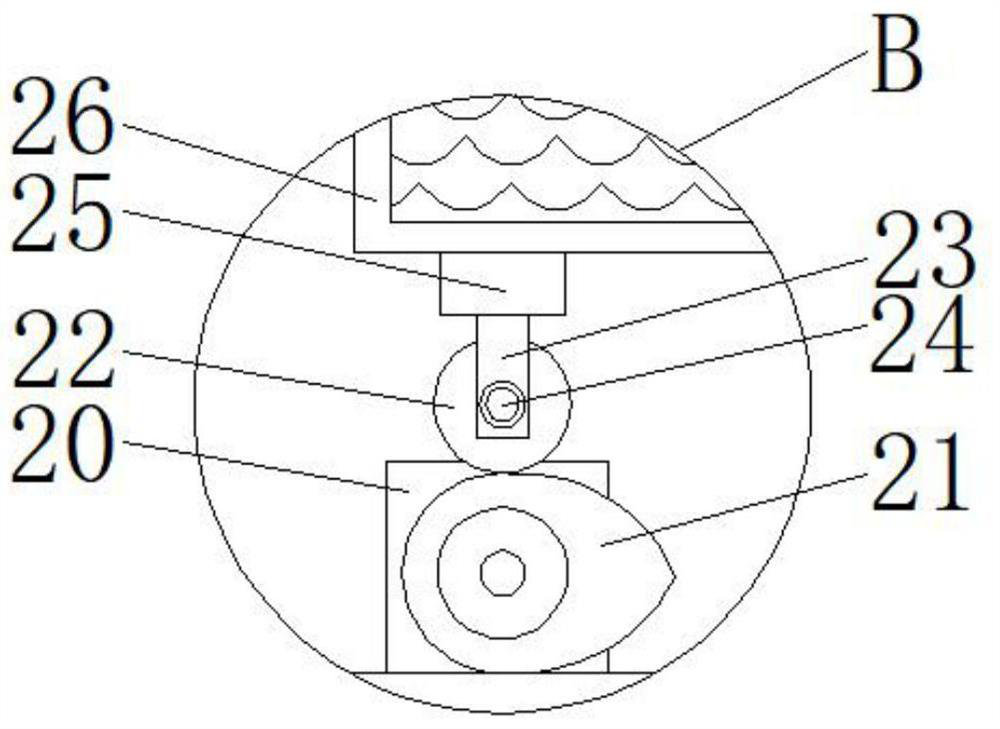

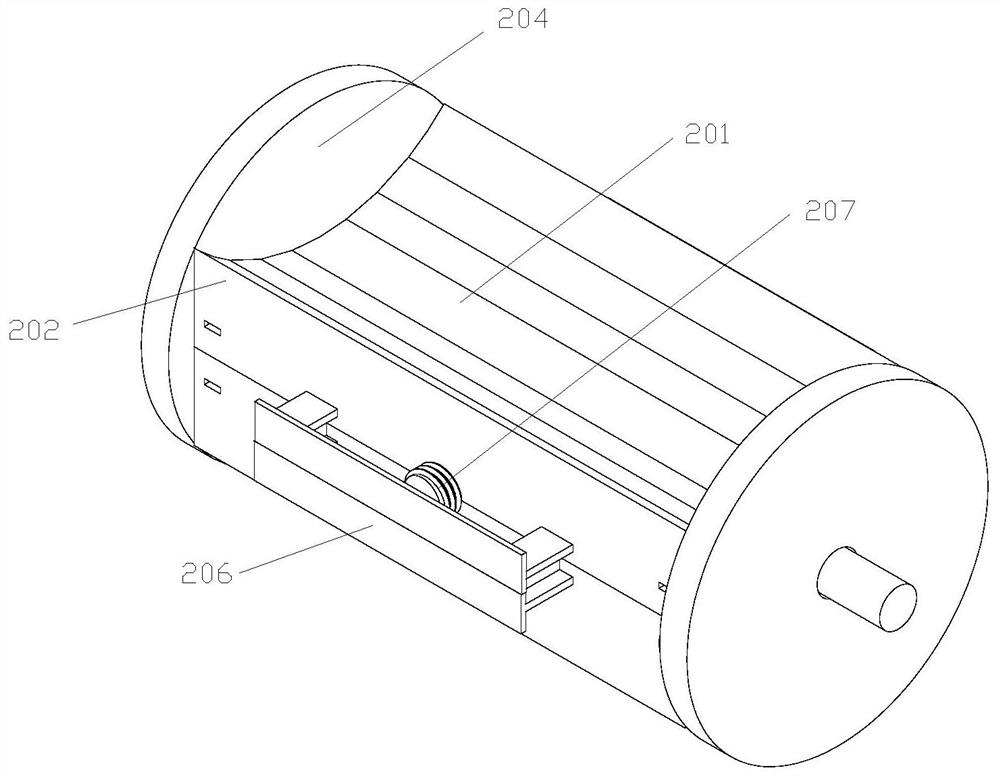

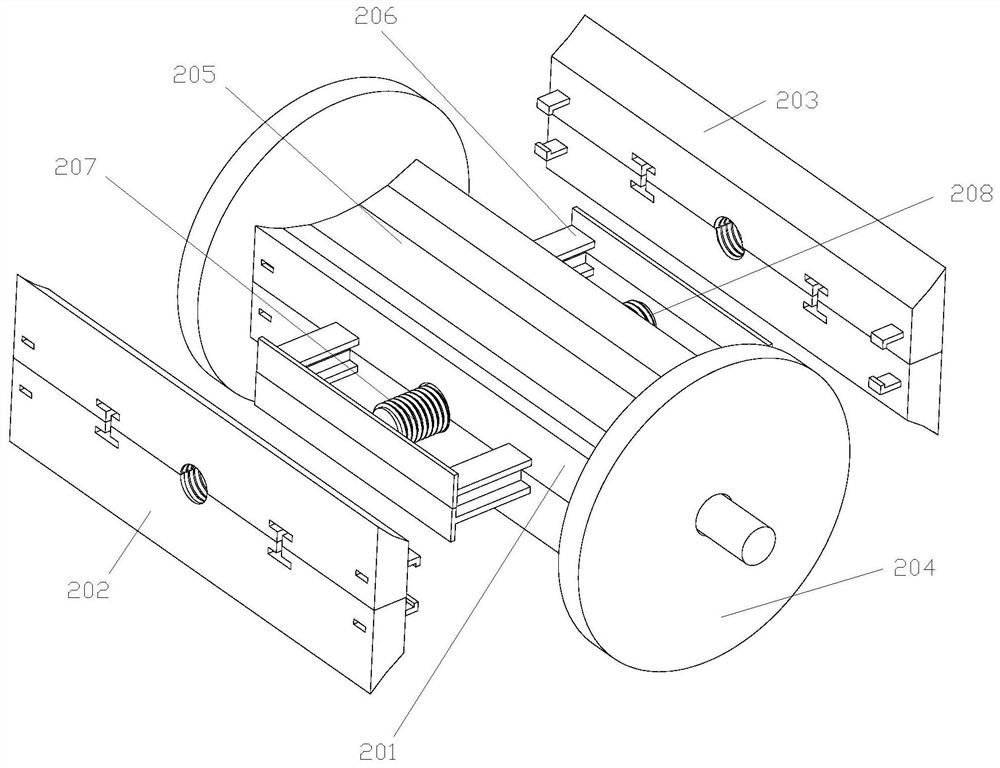

Screen cleaning equipment

ActiveCN112742828AAchieve cleaningRealize clamping and fixingDispersed particle filtrationDirt cleaningDisplay deviceEngineering

The invention discloses screen cleaning equipment, and particularly relates to the technical field of screen cleaning equipment. The screen cleaning equipment comprises a shell, a door plate and universal wheels; a brushing mechanism is arranged at one end of the interior of the shell; clamping structures are arranged at the four corners of the other end of the interior of the shell correspondingly; a waste liquid tank is fixedly connected to the bottom end of the interior of the shell; a scraping and washing mechanism is arranged at one end of the top of the inner side of the shell; a spraying mechanism is arranged in the top end of the shell; and dust collecting mechanisms are arranged on the two sides of the other end of the shell correspondingly. According to the screen cleaning equipment, a brushing mechanism is arranged at one end in the shell, a hydraulic air cylinder is started to drive a brush cylinder on the left side to roll back and forth through a fixing rod connected with a telescopic rod at the output end of the hydraulic air cylinder, and at the moment, a first screw rod covering opposite threads can rotate up and down together by means of sliding blocks movably connected with the top and the bottom of a brush cylinder on the left side, and therefore, the purpose that a brush cylinder on the right side repeatedly brushes at the same time is achieved, so that the screen of a display is brushed more closely and comprehensively.

Owner:永康市陌桐电子科技有限公司

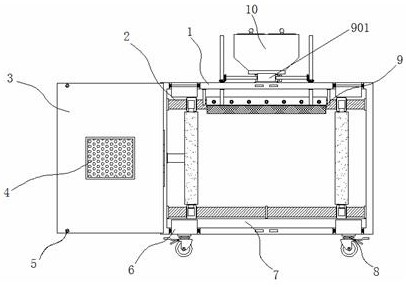

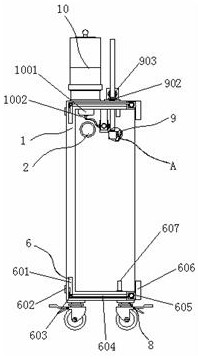

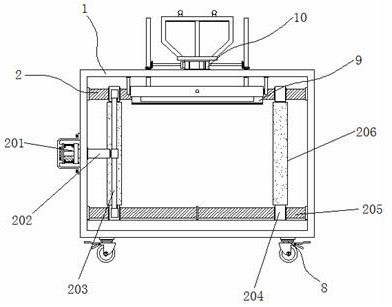

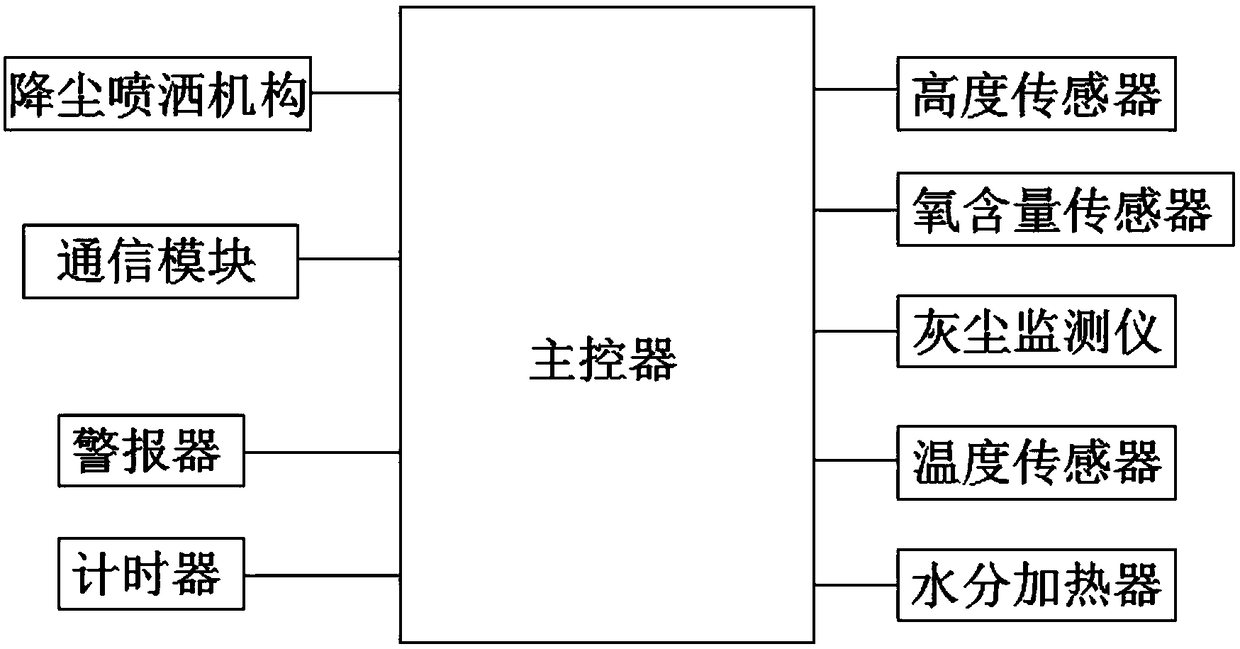

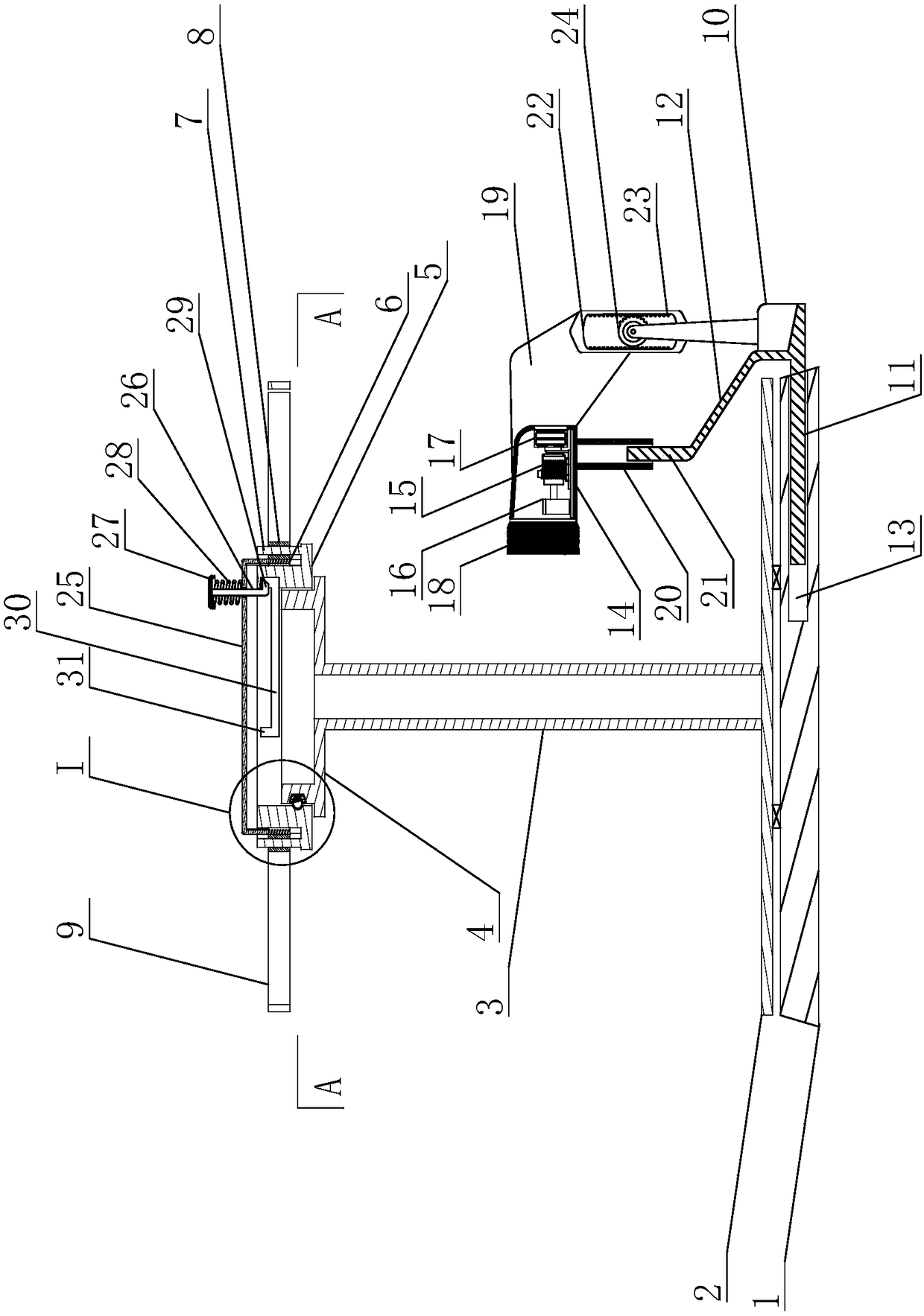

Intelligent dust removal system in coal mine and use method of system

ActiveCN108868868AIntelligent effect is goodImprove dust removal effectMining devicesDust removalCoal

The invention discloses an intelligent dust removal system in a coal mine and a use method of the system. The system comprises a roadway wall, and a spraying box walks vertically regularly on a vertical track on the roadway wall and stops temporarily at the prescribed place; by means of a dust monitor, the dust volume in the coal mine roadway is detected, once the dust volume exceeds a set threshold value, a temperature sensor detects the temperature of the portion consistent with the level of the spraying box and transmits the temperature into a main controller, the main controller performs spraying material control over a spray head according to a temperature value, and the spray head sprays corresponding dust removal materials according to the temperature value; by means of a height sensor, the height of the spraying box and the ground is detected, pressure of the spray head spraying the materials is controlled, the volume of the spraying materials is controlled through the dust volume; adjustment can be conducted according to the condition of the coal mine, and dust cleaning in the coal mine is conducted in time; the intelligent effect is good, dust removal can be conduced in the coal mine at different heights, and the protection and dust removal effects on a dust removal mechanism are good.

Owner:四川康盛洁环保科技有限公司

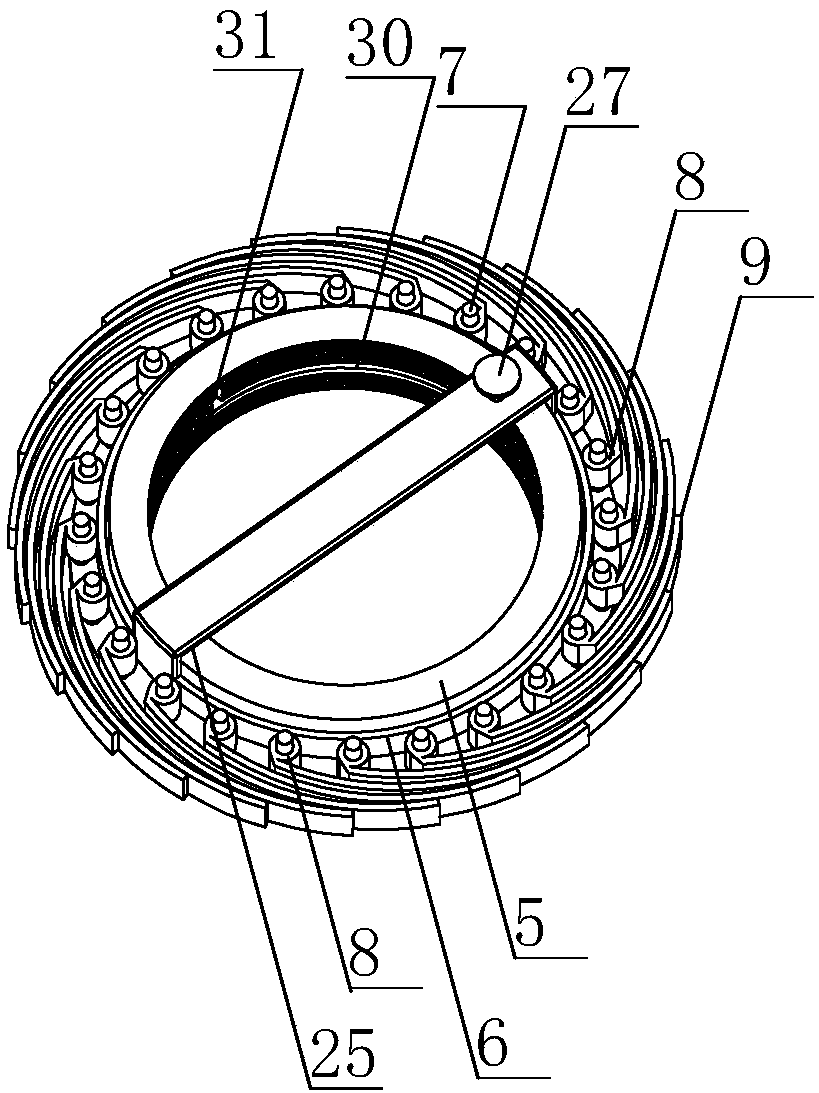

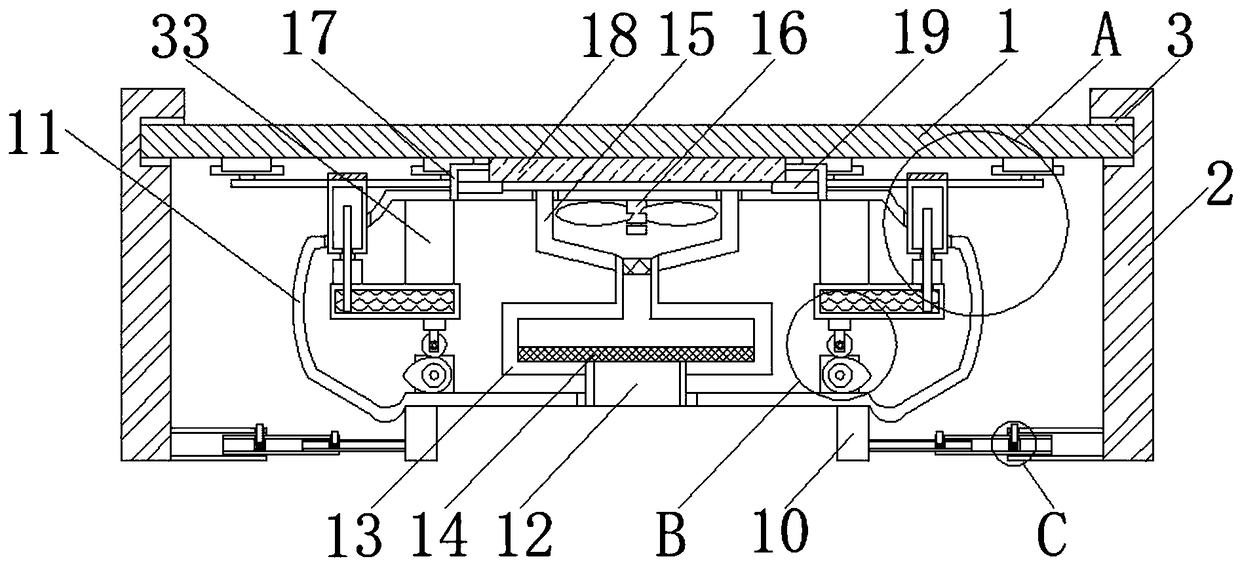

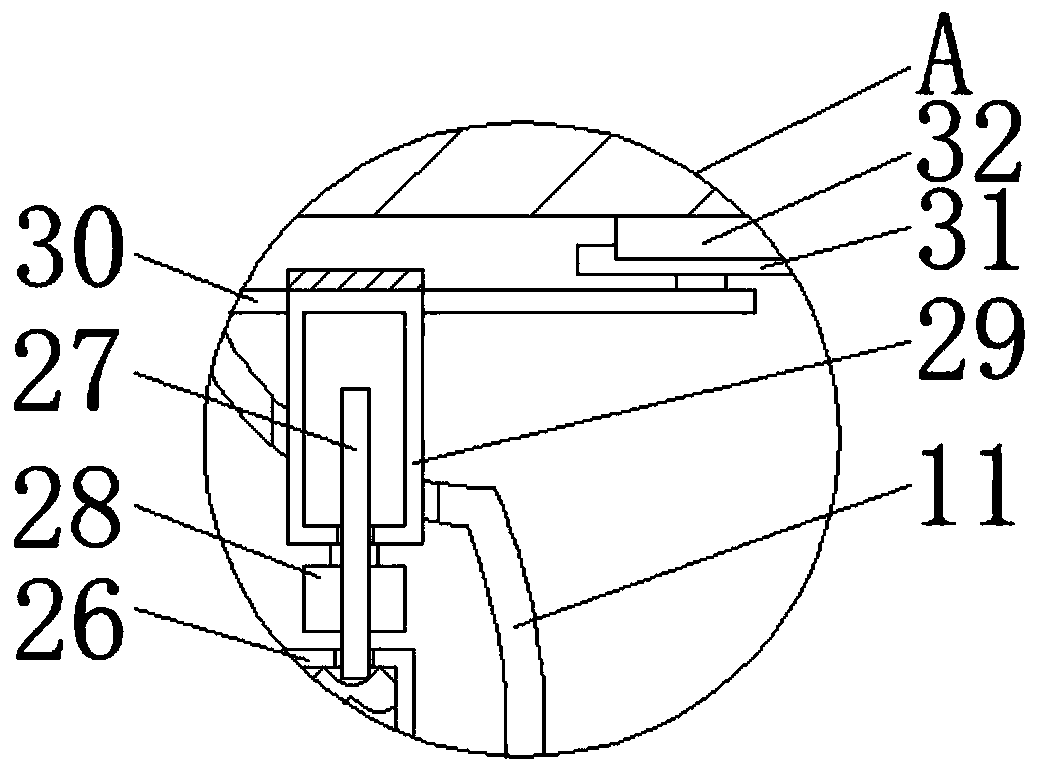

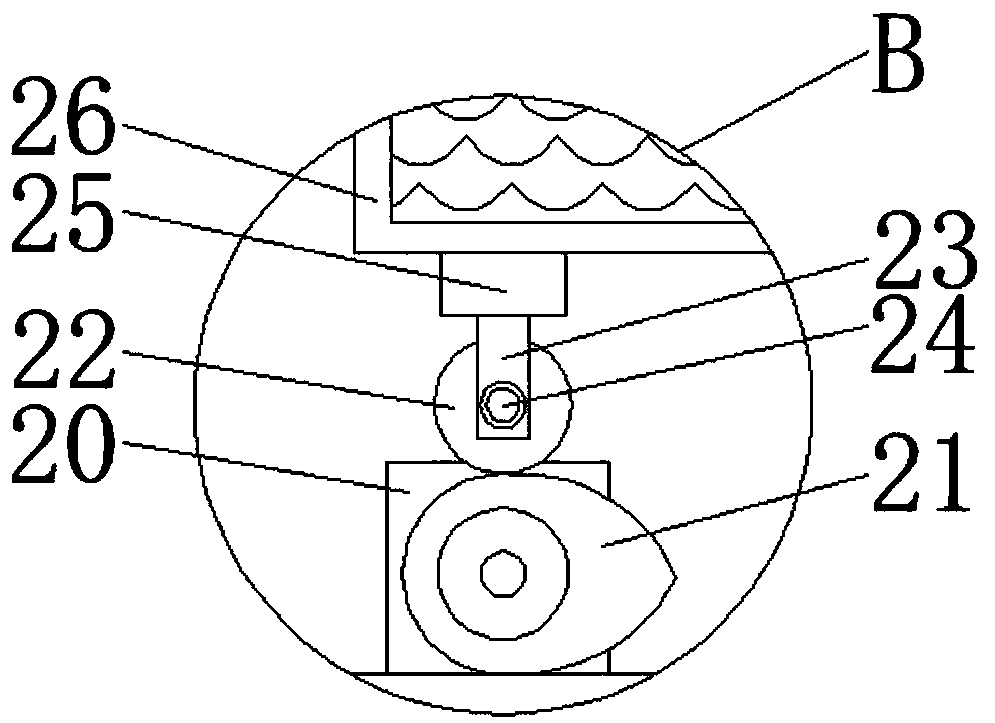

Cleaning and caring integrated machine for jewelries like bead strings

The invention discloses a cleaning and caring integrated machine for jewelries like bead strings and primarily relates to the field of jewelry devices. The cleaning and caring integrated machine comprises a base; a round bottom plate is rotationally connected to the top face of the base; a middle column is fixed to the center of the bottom plate; a convex base is arranged at the top end of the middle column; a machine frame is rotationally connected to the outer portion of the convex base in a limited mode; an outer gear ring is rotationally connected to the machine frame; a vertical shaft isarranged on the outer side of the outer gear ring; the bottom end of the vertical shaft is fixedly connected with the machine frame; a gear part is rotationally connected to the vertical shaft and engaged with the outer gear ring; an arc rod is fixed to the gear part, an elastic cord is fixed to the outer end of the arc rod, and the bottom end of the elastic cord is fixed to the edge of the bottomplate in an annular array mode; and a cleaning mechanism is arranged on the side of the base. The cleaning and caring integrated machine for the jewelries like the bead strings has the beneficial effects that the machine can separate beads on the bead strings automatically and clean and care the beads quickly and efficiently, labor is greatly relieved, and the cleaning and caring effect and efficiency are remarkably improved.

Owner:SHENZHEN XINWANFU JEWELRY

Cleaning device with maintenance and dust removal functions for furniture

ActiveCN108852173AClean in placeWith maintenance and dust removal functionCarpet cleanersFloor cleanersMotor driveArchitectural engineering

The invention discloses a cleaning device with maintenance and dust removal functions for furniture. The cleaning device comprises a table plate, wherein a table plate supporting sliding rod is movably connected with a side wall of the table plate; a sliding rod groove is formed in the surface of the table plate supporting sliding rod; one side of the table plate supporting sliding rod is fixedlyconnected with one end of a fixed pipe; an inner wall of the fixed pipe is movably connected with the surface of a retractable sleeve; the inner wall of the retractable sleeve is fixedly connected with one end of a spring; one side of the spring is fixedly connected with the inner wall of the retractable sleeve. When a fan rotates, dust under a table is sucked into a filtering cover which is fixedly connected with the inner part of a dust storage box; a first motor drives a cam to rotate so that a cleaning agent plastic box, which is fixedly connected between an ejection rod and a fixed rod, is squeezed and a cleaning agent flows into a rotary rod through a discharging pipe; a second motor drives the rotary rod to rotate, and a hairbrush which is fixedly connected onto the rotary rod is used for cleaning and maintaining the bottom of the table plate, so that people can clean dirt and the dust under the table, without the need of squatting down.

Owner:王鸳

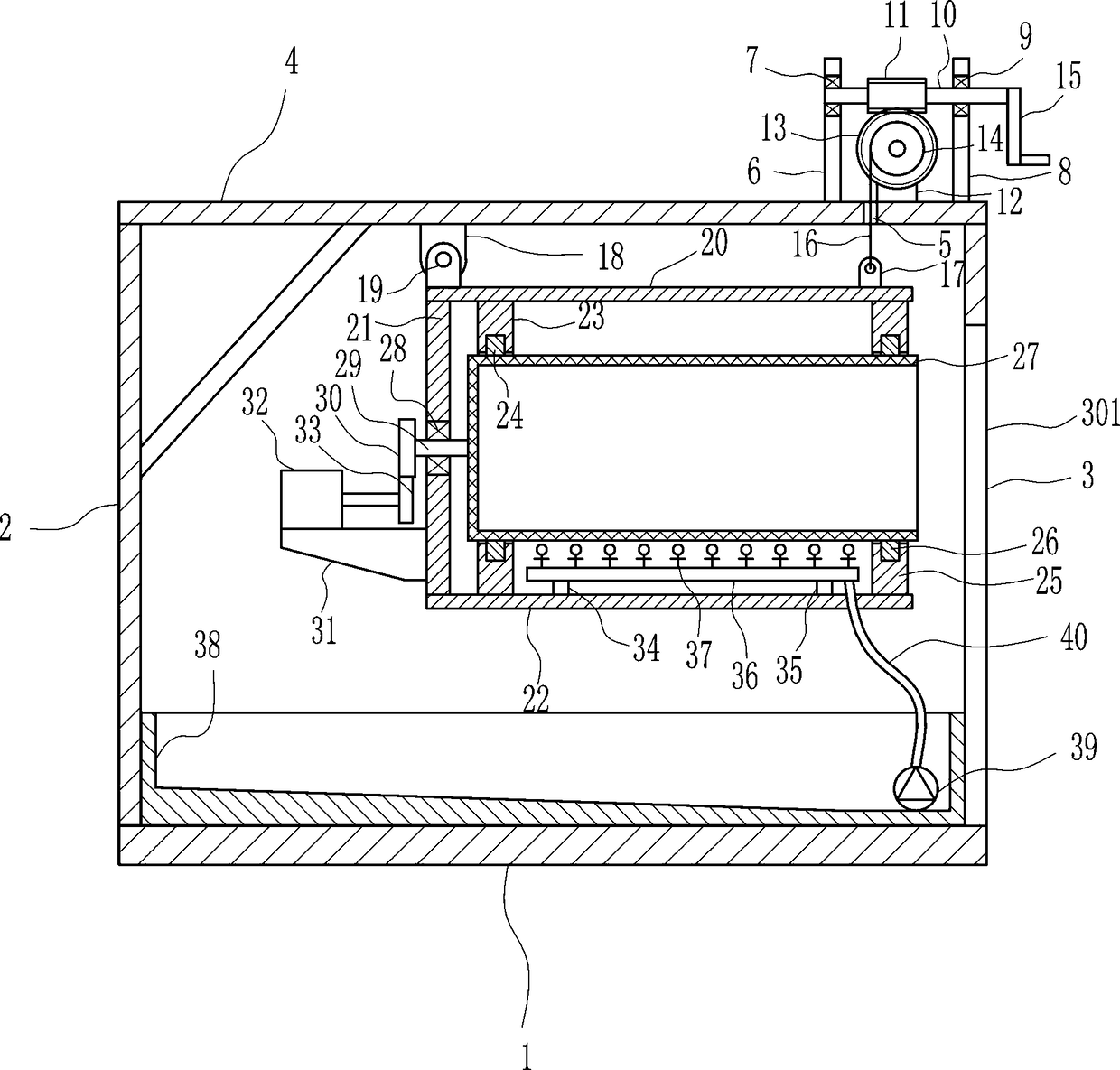

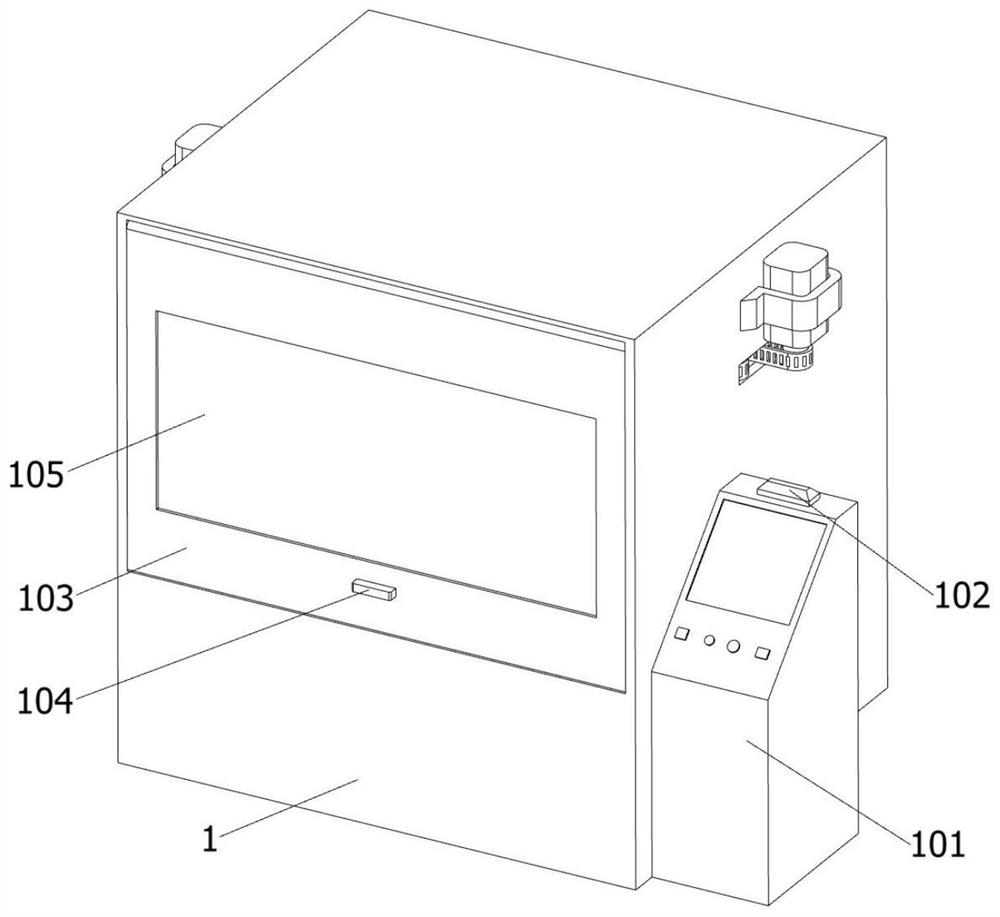

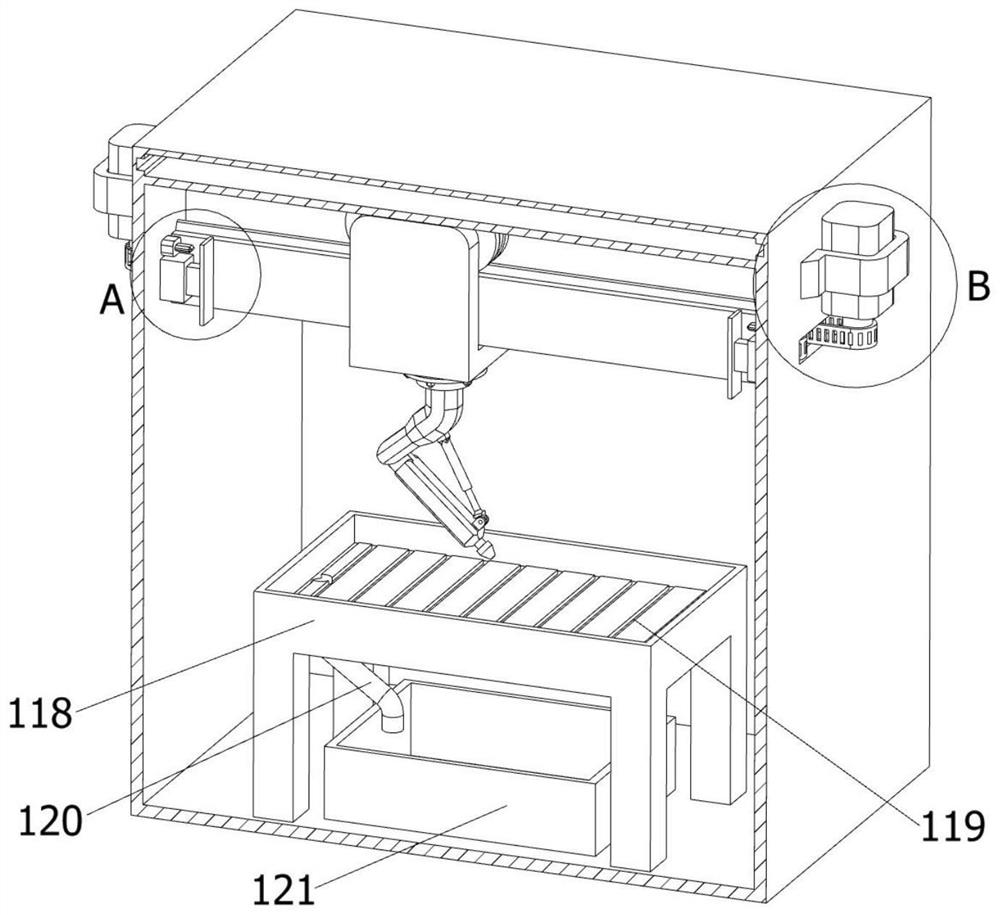

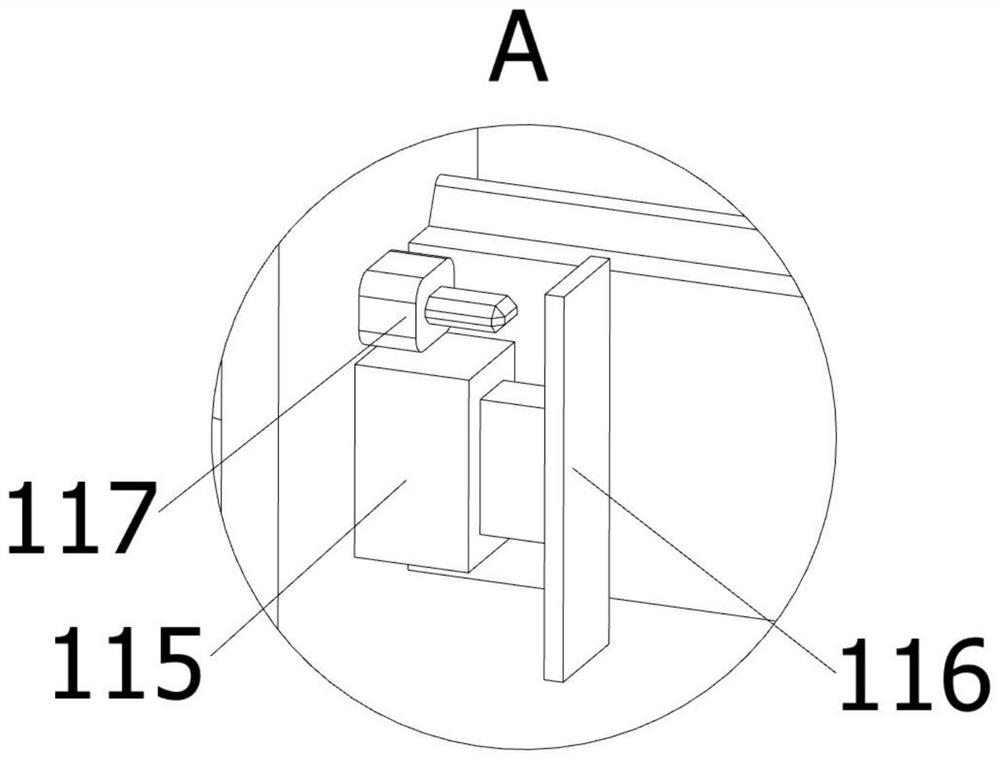

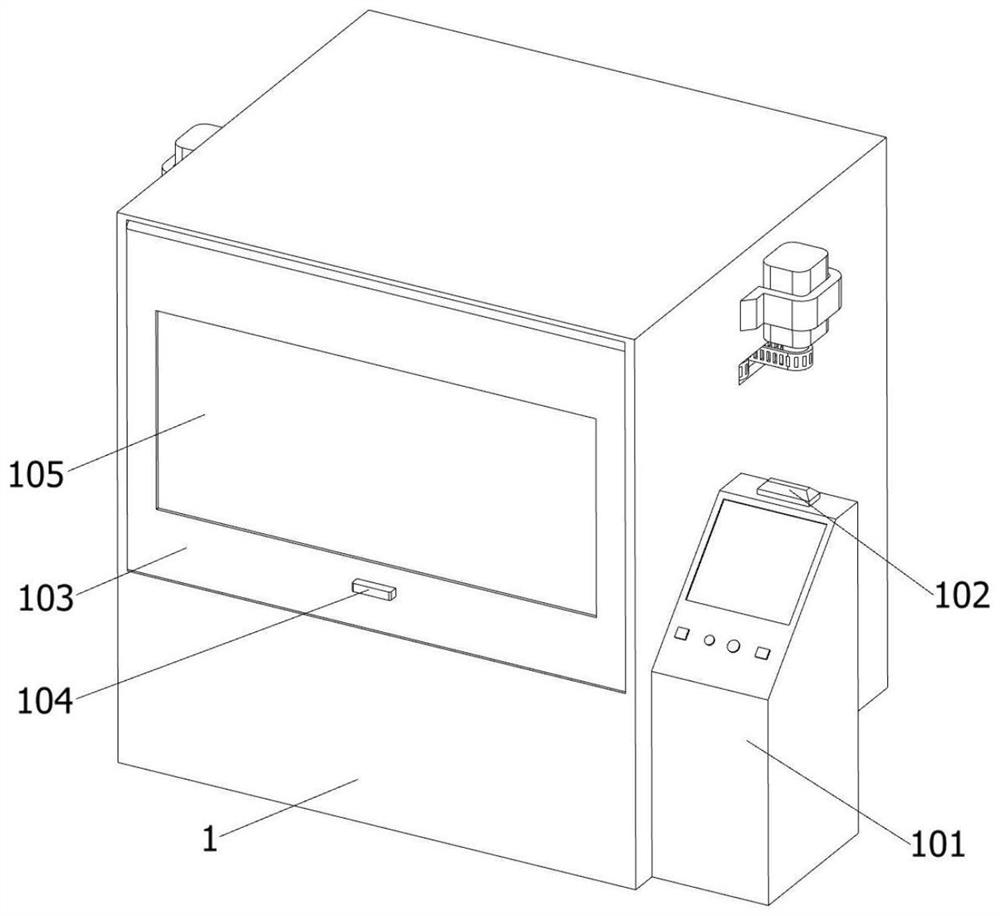

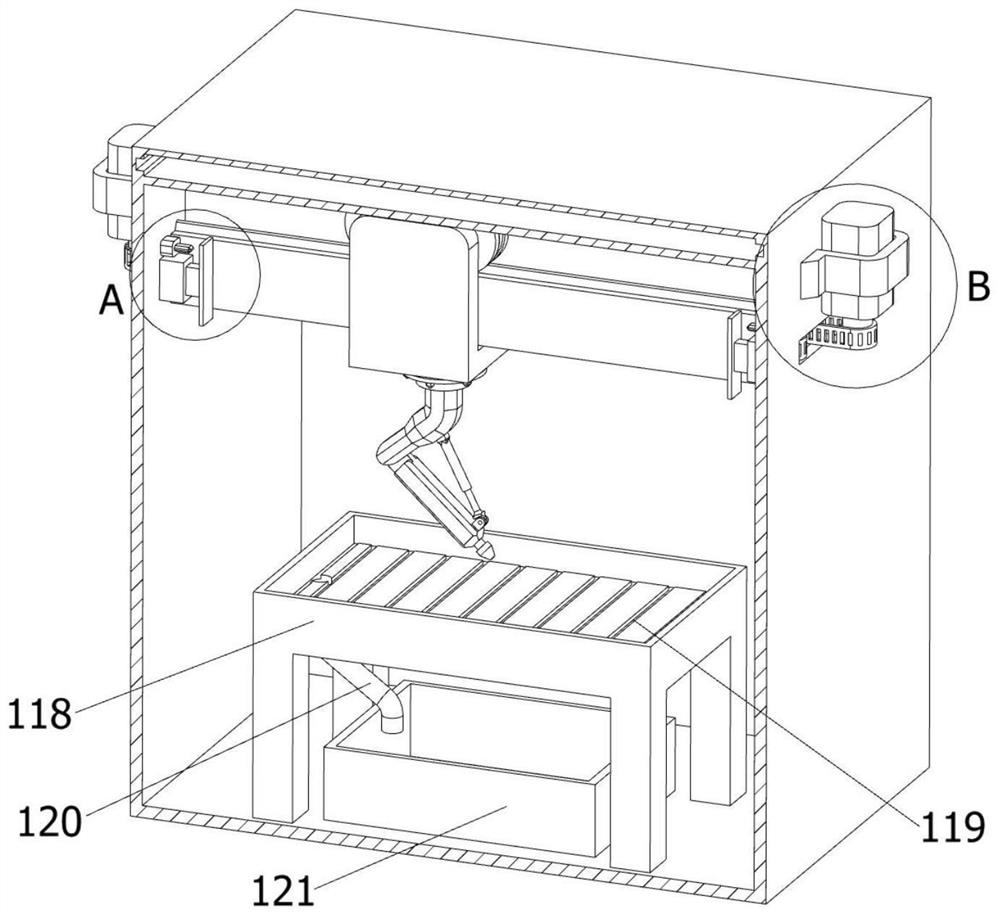

Timed cleaning equipment for mechanical parts on basis of remote control

ActiveCN112058755AAchieve protectionFlexible controlTransmissionCleaning using liquidsRemote controlMechanical equipment

The invention provides a timed cleaning equipment for mechanical parts on the basis of remote control, and relates to the technical field of mechanical equipment. With the timed cleaning equipment forthe mechanical parts on the basis of remote control, the problem that an existing cleaning equipment for the mechanical parts is simple in structure, single in function and insufficient in cleaning of the parts, so that impurities are left, the efficiency is low, and water resources are wasted is solved, and in addition, the problem that the existing cleaning equipment for the mechanical parts needs to consume manpower to watch, and automation is not achieved on programs is solved. The timed cleaning equipment for mechanical parts on the basis of remote control comprises a box body. The box body comprises a console. The right end of the box body is in bolted connection with the console, and a signal receiver is arranged at the top end of the console. A sliding platform is slidably connected with the interior of the box body. When the sliding platform moves to the edge of a transverse beam, the sliding platform makes contact with a buffer plate, the buffer plate is compressed and makescontact with a travel switch, the sliding platform can be enabled to stop moving, and therefore the alignment and limiting protection effects on the sliding platform are achieved.

Owner:苏州汇东华瑞科技咨询有限公司

Anti-fatigue manufacturing method of spiral bevel gear

ActiveCN103223577BConsistent resultsReduce heat treatment energy consumptionProcess systemsTechnology development

The invention relates to a novel composite surface-enhanced spiral bevel gear production process system based on a current anti-fatigue manufacturing method system and integrating induction quenching and gas nitriding. The invention aims to provide a composite surface-enhanced cyclo-palloid spiral bevel gear manufacturing method with heated precision of 4 to 6 levels and achieving the purpose that the theory contact zone meshed strength is meshed with carburizing and quenching strength. The invention aims to further provide a new spiral bevel gear production technology which can not only embody the current anti-fatigue high-end gear manufacturing method purpose, but also agree with the complete software and hardware match of a roadmap of heat treatment technology development in China.

Owner:天津市天瑞硬化工程有限公司

Washing method for washing machine

ActiveCN102776749BEasy to cleanClean in placeOther washing machinesControl devices for washing apparatusLaundry washing machineStart time

The invention provides a washing method for a washing machine. The washing machine comprises an internal tub, a motor, a draining valve and a main controller; and the washing method is characterized by comprising the following steps: (1) normally washing; (2) rinsing for a plurality of times; (3) completing the rinsing, starting the draining valve to access a draining state, wherein the delay starting time of the motor is T1; (4) electrifying the motor to drive the internal tub to rotate, wherein the rotary cleaning time is T2; (5) after completing once rotary cleaning, interrupting the power supply of the motor to drive the internal tub to rotate under inertia, wherein the rotating time under inertia is T3; (6) determining whether the circular cleaning time N of the internal tub reaches a preset value, if so, entering the next step, if not, returning to step (4); (7) electrifying the motor to enter a dewatering program, wherein the dewatering time is T4; (8) stopping the motor to complete the dewatering, and judging whether the rinsing at the time is the last rinsing, if so, entering the next step, if not, returning to step (2); and (9) drying in the air. According to the washing method, the tub is cleaned following the rinsing at each time, thus, the washing tub is repeatedly cleaned for a plurality of times, and the washing tub can be ensured to be cleaned efficiently.

Owner:NINGBO XINLE HOUSEHOLD APPLIANCES

A furniture cleaning device with maintenance and dust removal function

ActiveCN108852173BWith maintenance and dust removal functionClean in placeCarpet cleanersFloor cleanersDust controlStructural engineering

The invention discloses a cleaning device with maintenance and dust removal functions for furniture. The cleaning device comprises a table plate, wherein a table plate supporting sliding rod is movably connected with a side wall of the table plate; a sliding rod groove is formed in the surface of the table plate supporting sliding rod; one side of the table plate supporting sliding rod is fixedlyconnected with one end of a fixed pipe; an inner wall of the fixed pipe is movably connected with the surface of a retractable sleeve; the inner wall of the retractable sleeve is fixedly connected with one end of a spring; one side of the spring is fixedly connected with the inner wall of the retractable sleeve. When a fan rotates, dust under a table is sucked into a filtering cover which is fixedly connected with the inner part of a dust storage box; a first motor drives a cam to rotate so that a cleaning agent plastic box, which is fixedly connected between an ejection rod and a fixed rod, is squeezed and a cleaning agent flows into a rotary rod through a discharging pipe; a second motor drives the rotary rod to rotate, and a hairbrush which is fixedly connected onto the rotary rod is used for cleaning and maintaining the bottom of the table plate, so that people can clean dirt and the dust under the table, without the need of squatting down.

Owner:王鸳

A kind of edible pupa cleaning equipment

InactiveCN108906718BAchieve cleaning functionAchieve the buffer functionCleaning using toolsCleaning using liquidsStructural engineeringMechanical engineering

The invention relates to a cleaning device, in particular to a cleaning device for edible pupae. The technical problem of the present invention is to provide an edible pupa cleaning device with thorough cleaning, proper cleaning force and simple operation. The technical solution of the present invention is: an edible pupa cleaning equipment, including a base, a first support, a second support, a third support, a first fixing plate, a first bearing seat, a second fixing plate, a second bearing seat, The first rotating shaft, etc.; the first bracket is fixedly connected to the upper left side of the base, the second bracket is fixedly connected to the upper right side of the base, a through hole is opened on the second bracket, and the tops of the first bracket and the second bracket are fixed. A third bracket is connected, and a guide hole is opened on the right side of the third bracket. The invention achieves the function of cleaning edible pupae, not only realizes the filtration of water, but also realizes the function of replacing manual cleaning. The invention has the characteristics of simple operation, proper cleaning, and appropriate cleaning force.

Owner:南京幸庄科技创新产业园管理有限公司

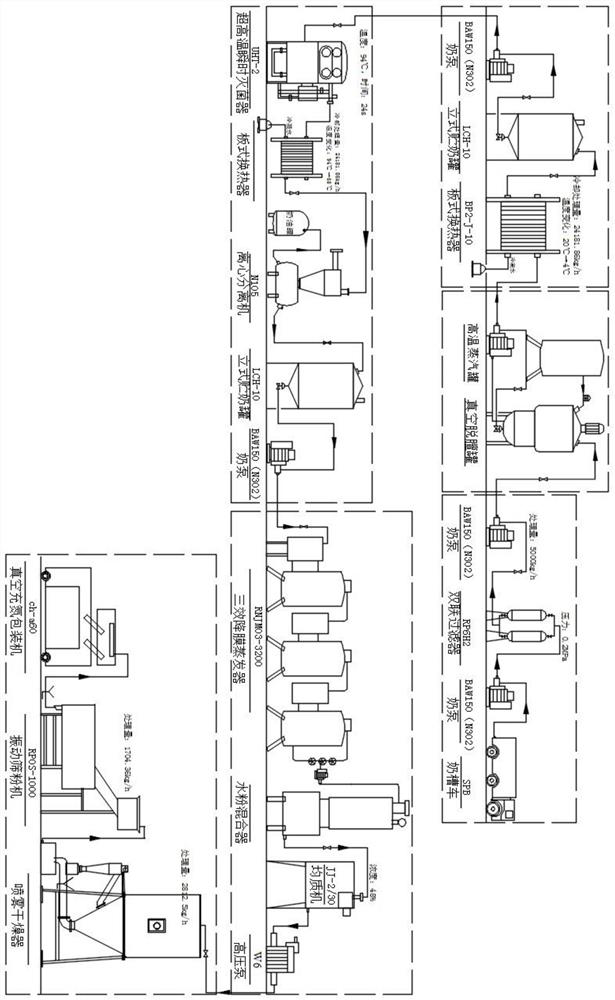

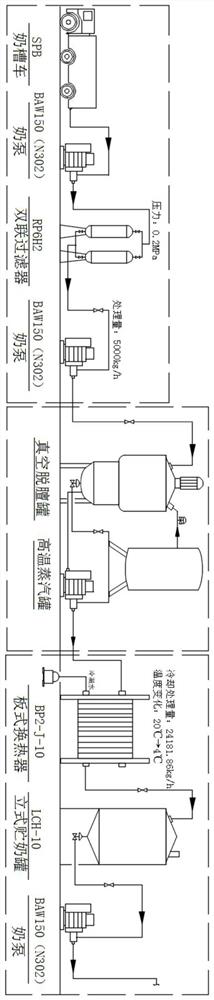

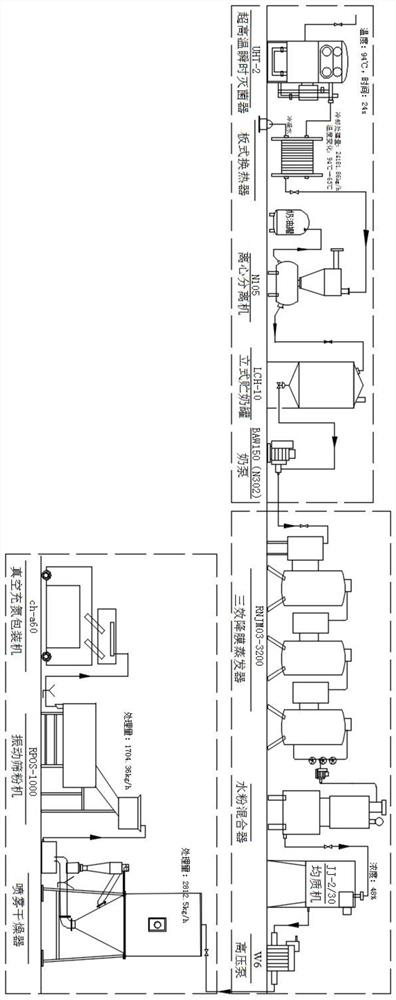

Spray drying method for goat milk

InactiveCN111802456ASatisfy processingClean in placeMilk preparationOther dairy technologyProcess engineeringSpray dried

The invention relates to the technical field of processing of goat milk, in particular to a spray drying method for goat milk. The spray drying method for the goat milk comprises the following steps:(1) pumping raw milk out of a milk tank car into a double filter through a first milk pump for filtering to obtain raw milk subjected to primary filtering; (2) pumping the raw milk subjected to primary filtering into a vacuum de-muttony tank through a second milk pump for de-muttony treatment to obtain milk without muttony odour; and (3) pumping the milk without muttony odour out of the vacuum de-muttony tank into a plate-type heat exchanger through a third milk pump for cooling, and then storing obtained goat milk in a vertical milk storage tank. Compared with an existing spray drying methodfor goat milk, the spray drying method for the goat milk has the advantages that the requirements of efficient processing and de-muttony of multiple kinds of goat milk are met, the whole system and technology can automatically run through control of a PLC at the same time, long-term continuous stable running is guaranteed, the acceptance level of people of the goat milk is greatly raised, good color, fragrance, looseness, liquidity and dispersity of goat milk powder are maintained, and the goat milk powder can be fast dissolved during brewing, so that a novel breakthrough of the spray drying technology for the goat milk is achieved.

Owner:金诚

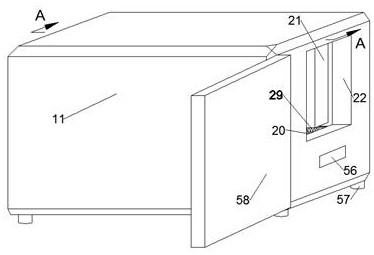

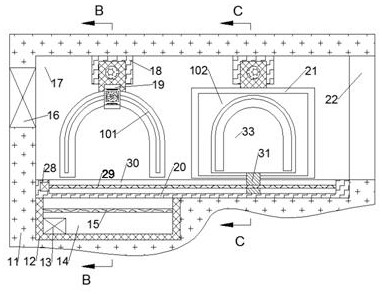

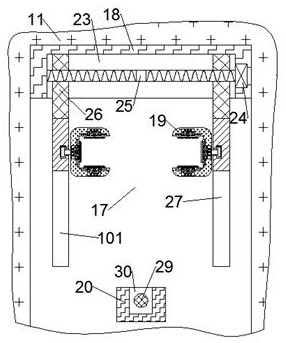

A washing method of drum washing machine

ActiveCN108411562BEnsure smoothnessSave energyHollow article cleaningOther washing machinesLaundry washing machineInlet valve

Owner:NINGBO XINLE HOUSEHOLD APPLIANCES

Dental prosthesis nursing instrument

InactiveCN114176819AGuaranteed uptimeRealize the recycling functionDrying gas arrangementsTooth rinsingDenturesNursing care

The artificial tooth nursing instrument comprises a machine body shell, a working cavity is formed in the machine body shell, a cleaning fluid box is arranged on the bottom wall of the working cavity, a cleaning fluid storage cavity with an upward opening is formed in the cleaning fluid box, a water pump is arranged on the bottom wall of the cleaning fluid storage cavity, and a filter screen fixedly connected with the cleaning fluid storage cavity is arranged above the water pump; a third motor can control a brush fixing block to slide in the shape of a third limiting sliding groove, a fourth motor can drive a brush to rotate to brush away food residues and some sundries attached to false teeth, the function of removing solid sundries on the false teeth is achieved, a vibration generator can enable the brush to vibrate while rotating, and therefore the false teeth can be removed. The brush can clean solid impurities in gaps of false teeth more deeply, and the function that cleaning is more in place is achieved.

Owner:张枫

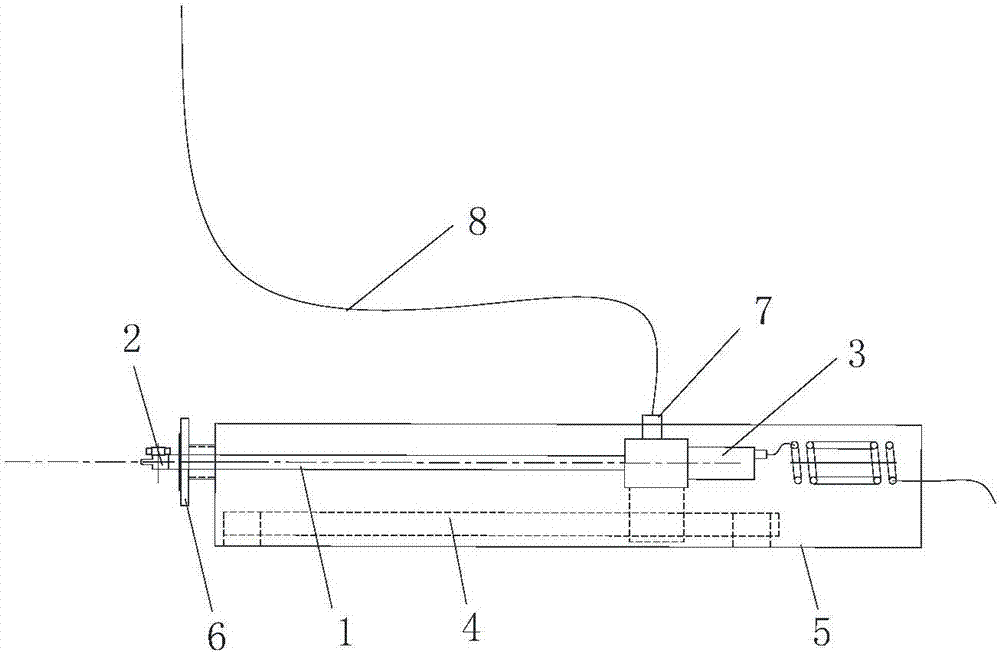

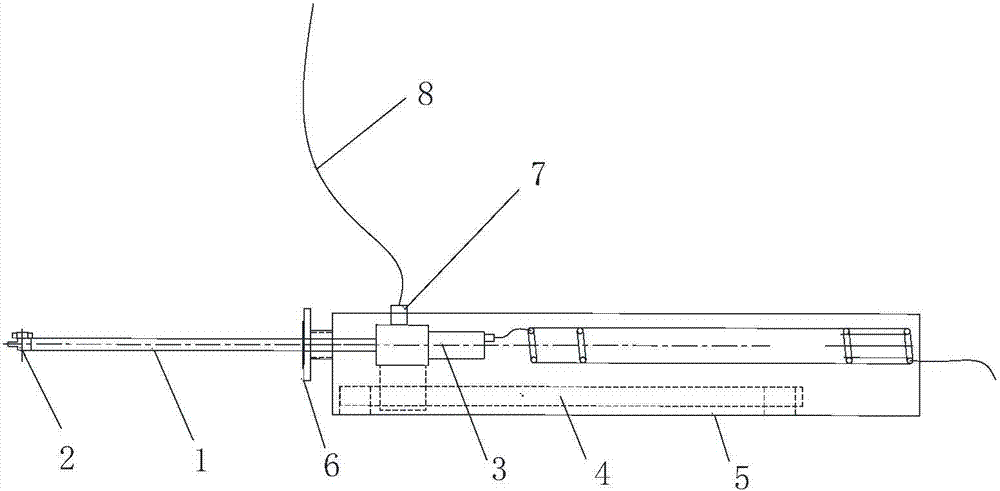

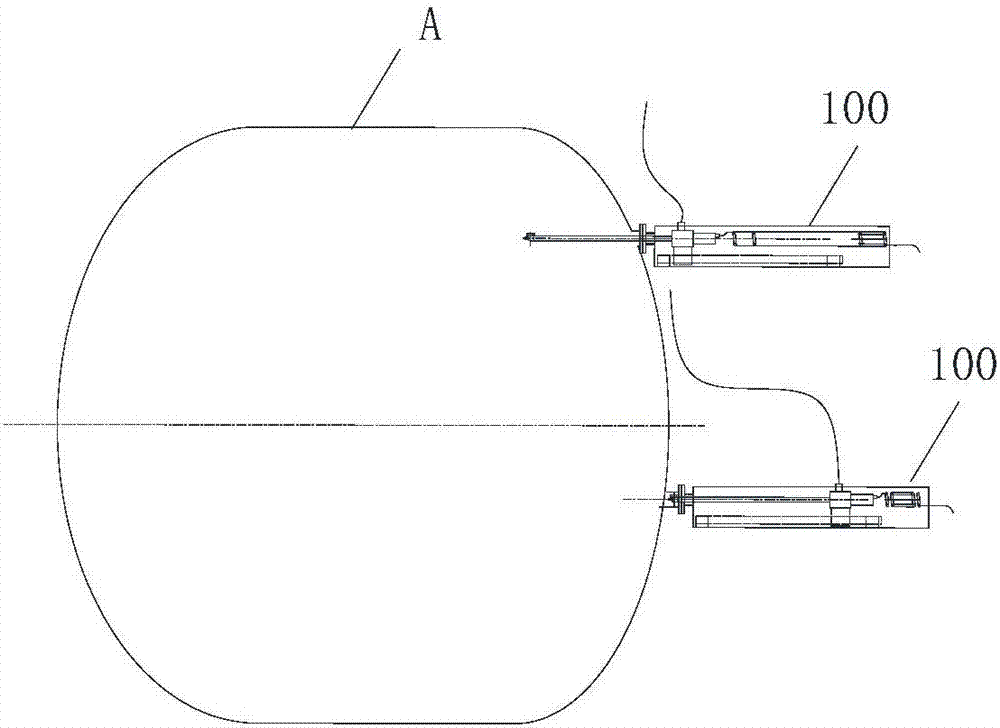

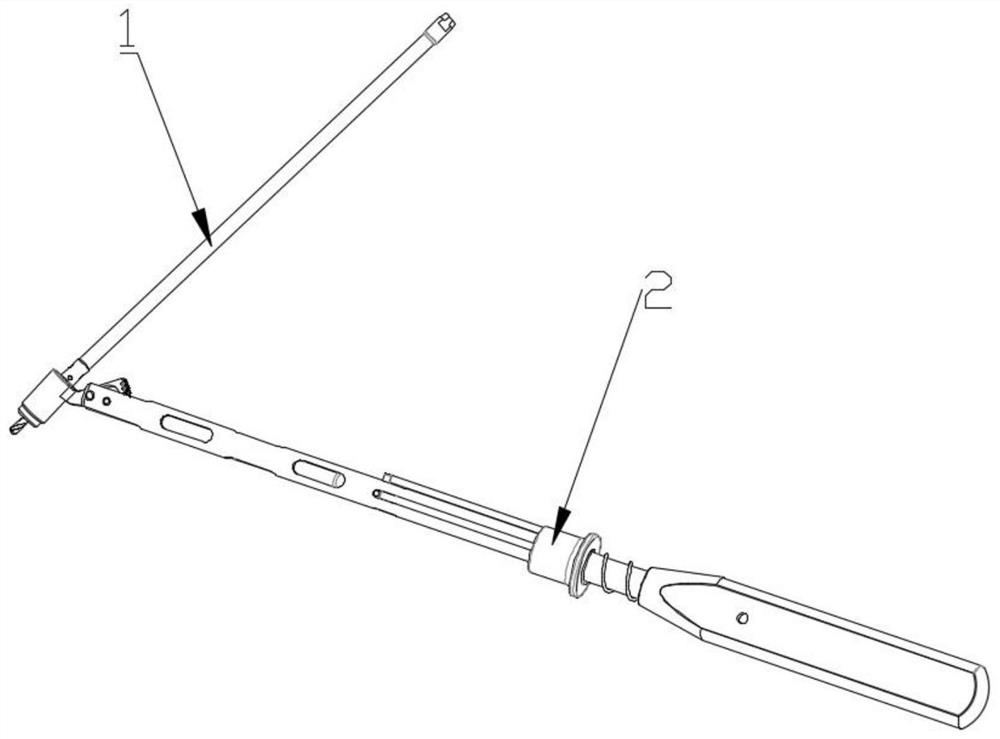

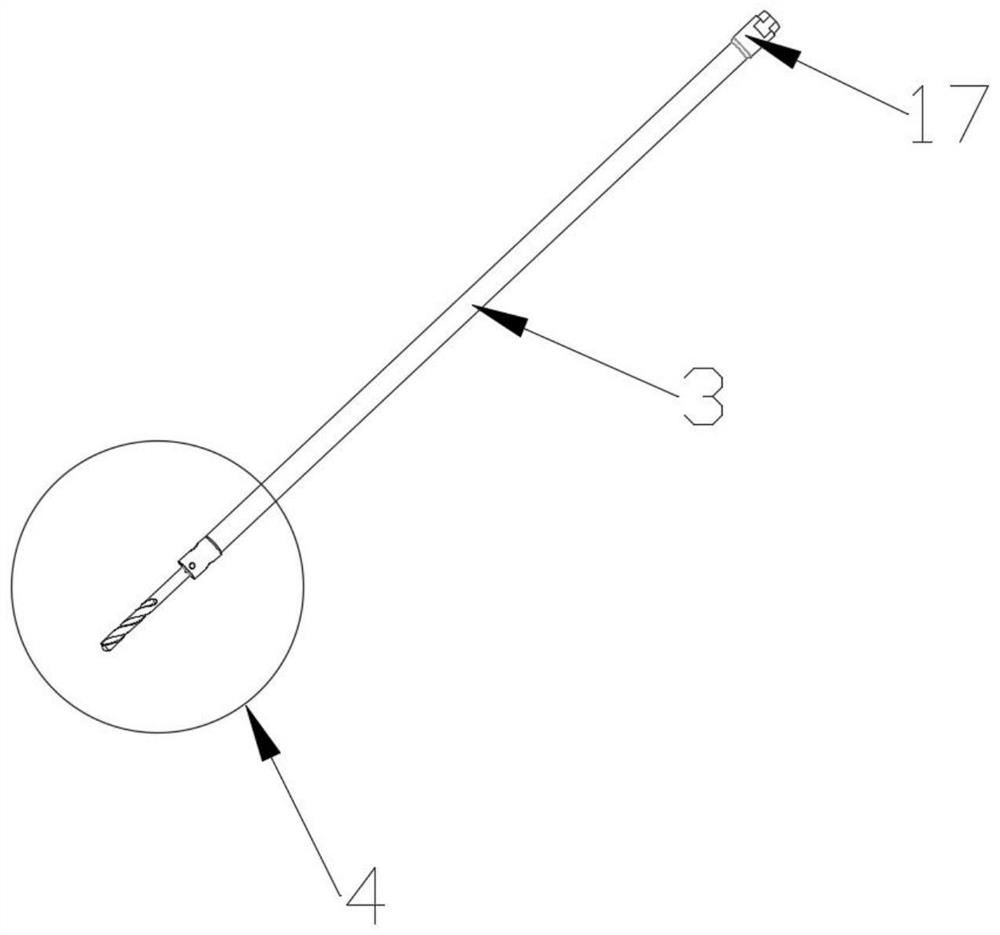

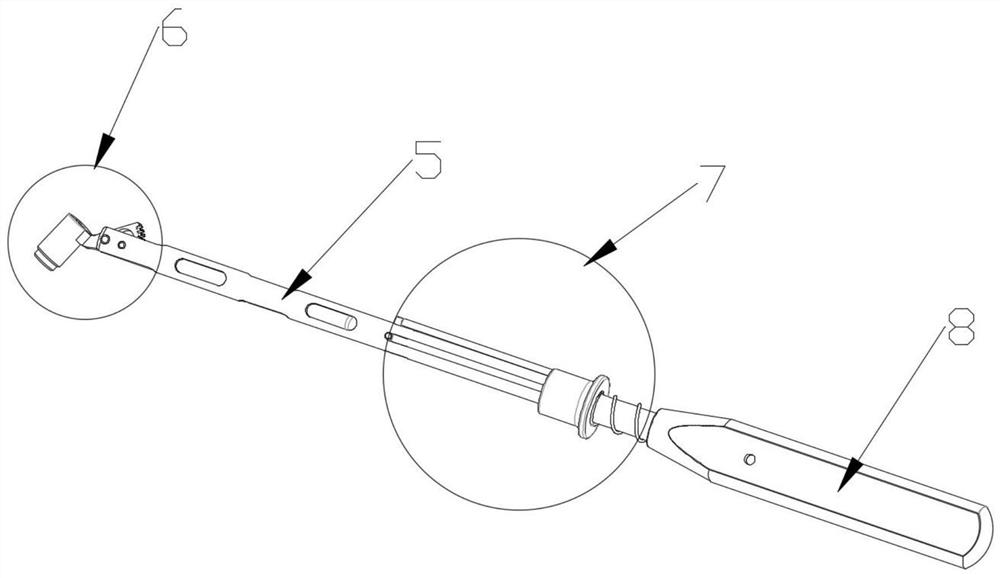

Direction-adjustable acetabulum drilling tool

The invention discloses a direction-adjustable acetabulum drilling tool. The direction-adjustable acetabulum drilling tool comprises a universal drill, and a guider; the universal drill consists of atransmission rod, and a universal drill bit mechanism; the universal drill bit mechanism is located on one side of the transmission rod; the guider consists of a main rod, an adjustable guide mechanism, a pressing mechanism, and a handle; the adjustable guide mechanism is located at one end of the main rod; the handle is located at one end, away from the adjustable guide mechanism, of the main rod; and the pressing mechanism is located on the outer side of the middle part of the main rod. The universal drill of the direction-adjustable acetabulum drilling tool is different from a traditional steel wire soft drill that the universal drill rotates through a spherical structure so as to achieve universal adjustment, so that cleaning dead corner is eliminated with complete postoperative cleaning realized, thereby enabling repeated use; and moreover, the angle of the front end of the guider can be adjusted through the adjustable guide mechanism, so that a proper guide angle can be found byan operator according to the space shape of the acetabular fossa, thereby ensuring more reasonable use of the universal drill and the guider.

Owner:天衍医疗器材有限公司

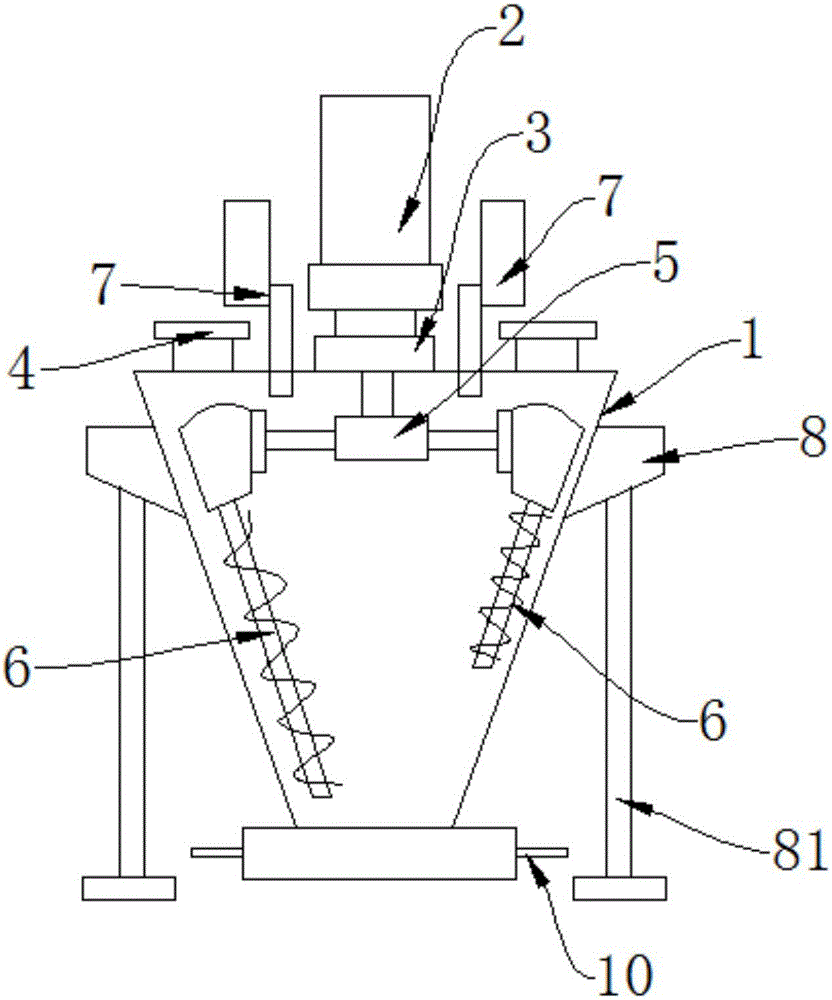

Environment-friendly domestic rabbit feeding device and feeding method thereof

The invention provides an environment-friendly domestic rabbit feeding device and a feeding method thereof. The environment-friendly domestic rabbit feeding device comprises a stock bin, feeding troughs, a feed conveying mechanism used for conveying feeds in the stock bin into the feeding troughs, and a powder filtering mechanism, wherein one end of the feed conveying mechanism is connected with the stock bin, a discharge port used for charging the feeds into the feeding troughs is formed in the feed conveying mechanism, and the powder filtering mechanism is arranged on the lower side of the feed conveying mechanism so as to filter and recycle feed powder in the feed conveying mechanism. According to the environment-friendly domestic rabbit feeding device disclosed by the invention, the powder obtained after filtration and separation of the feeds is recycled, the recycled powder is secondarily made into blocky feeds through a granulator, and then the blocky feeds are used for feeding domestic rabbits again, so that waste is avoided, and environment-friendly feeding of domestic rabbits is realized.

Owner:龙岩市万家兔业发展有限公司

Mechanical part timing cleaning equipment based on remote control

InactiveCN114669534AAchieve protectionFlexible controlCleaning using liquidsRemote controlControl engineering

The invention provides mechanical part timing cleaning equipment based on remote control, relates to the technical field of mechanical equipment, and solves the problems that on one hand, existing mechanical part cleaning equipment is simple in structure and single in function, cleaning of parts is not fine enough, sundries are left, efficiency is low, and water resources are wasted; and in addition, the existing cleaning equipment for the mechanical parts needs to consume manpower for guarding, and an automatic program is not realized. The invention discloses mechanical part timing cleaning equipment based on remote control. The mechanical part timing cleaning equipment comprises a box body; the box body comprises a console, the right end of the box body is in bolted connection with the console, and a signal receiver is arranged at the top end of the console; a sliding platform is connected into the box body in a sliding mode. When the sliding platform moves to the edge of the cross beam, the sliding platform touches the buffer plate, the buffer plate is compressed and touches the travel switch, the sliding platform can stop moving, and therefore the effects of alignment and limiting protection of the position of the sliding platform are achieved.

Owner:苏州迪美宏精密科技有限公司

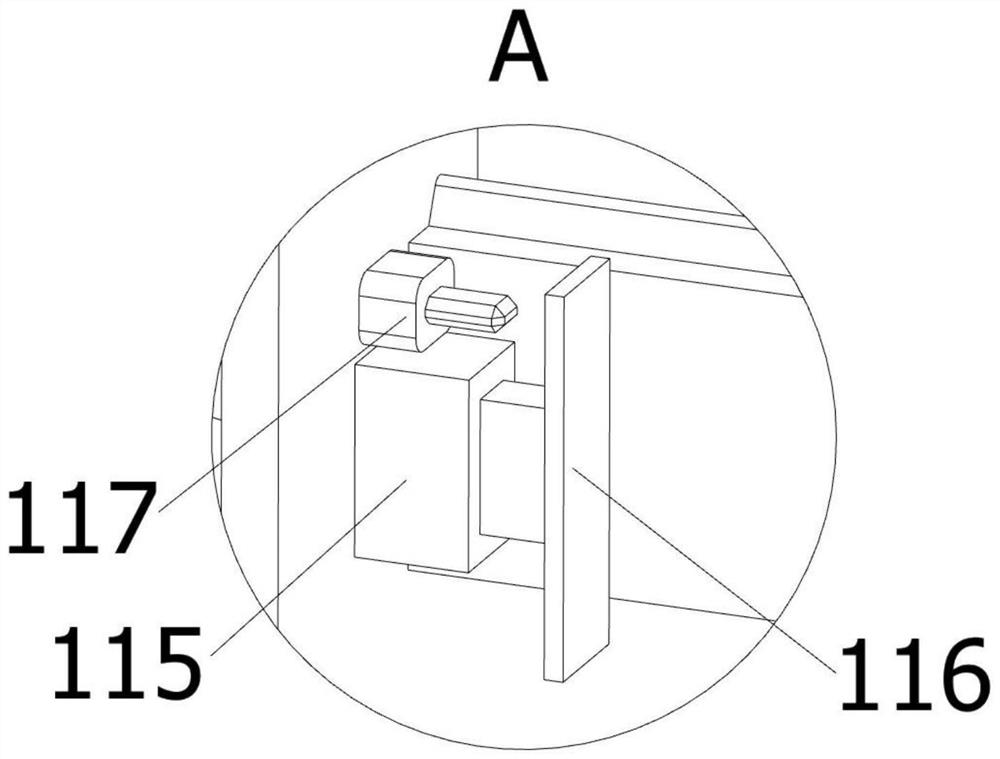

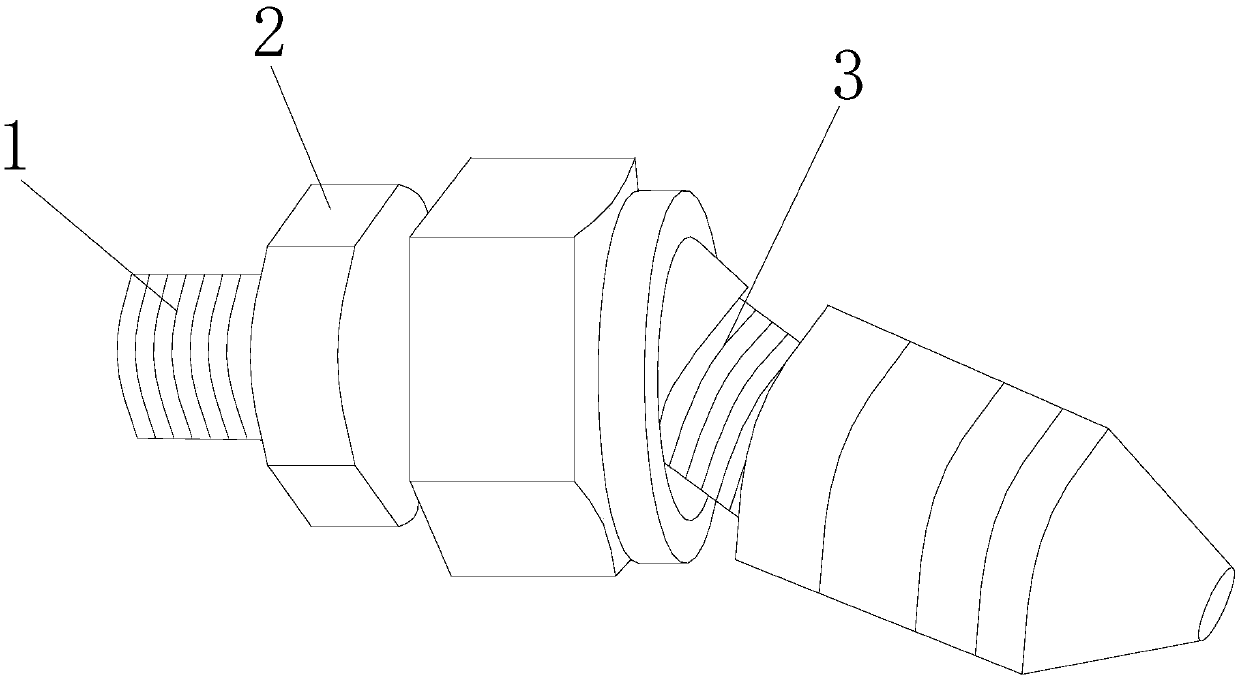

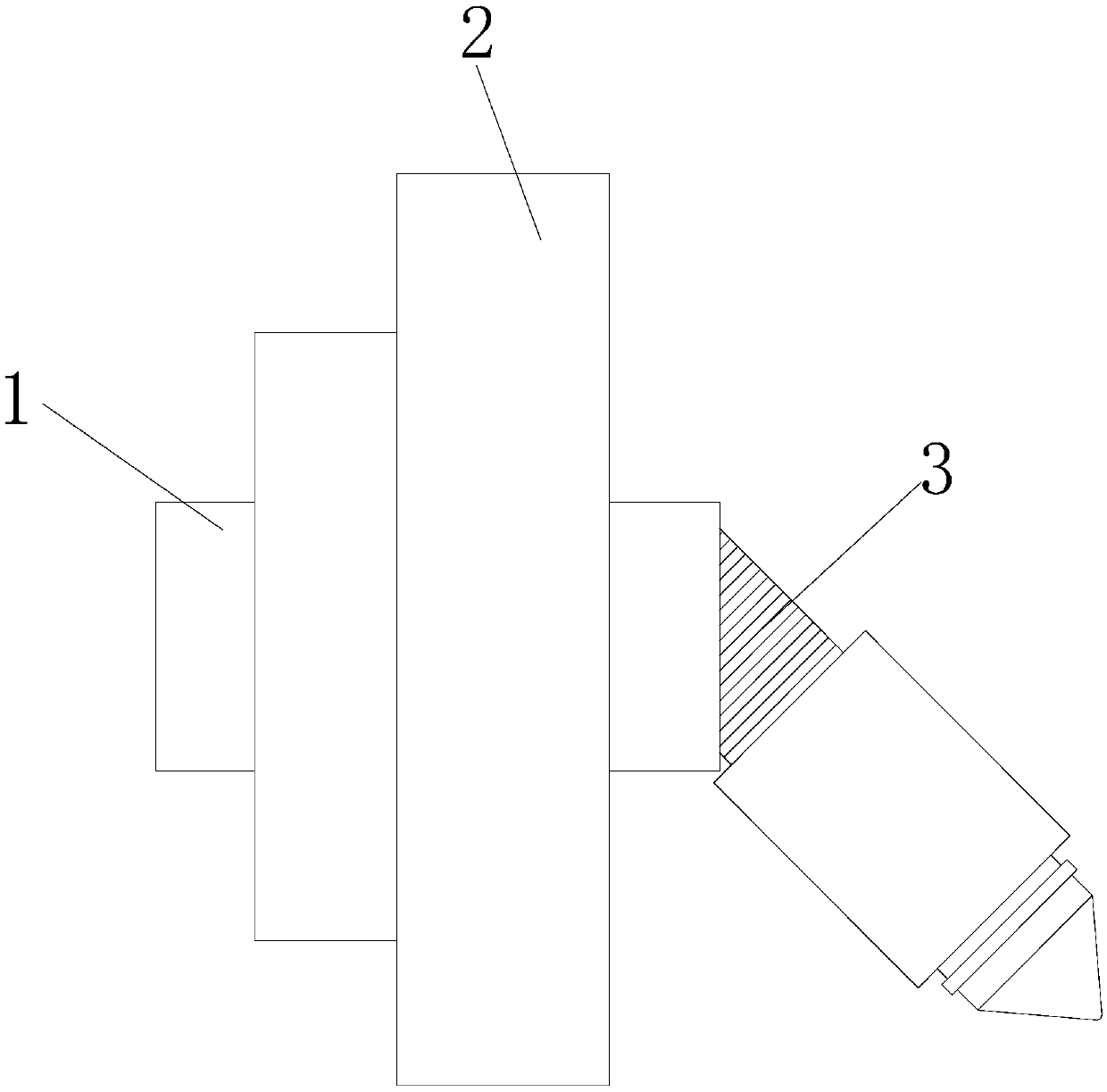

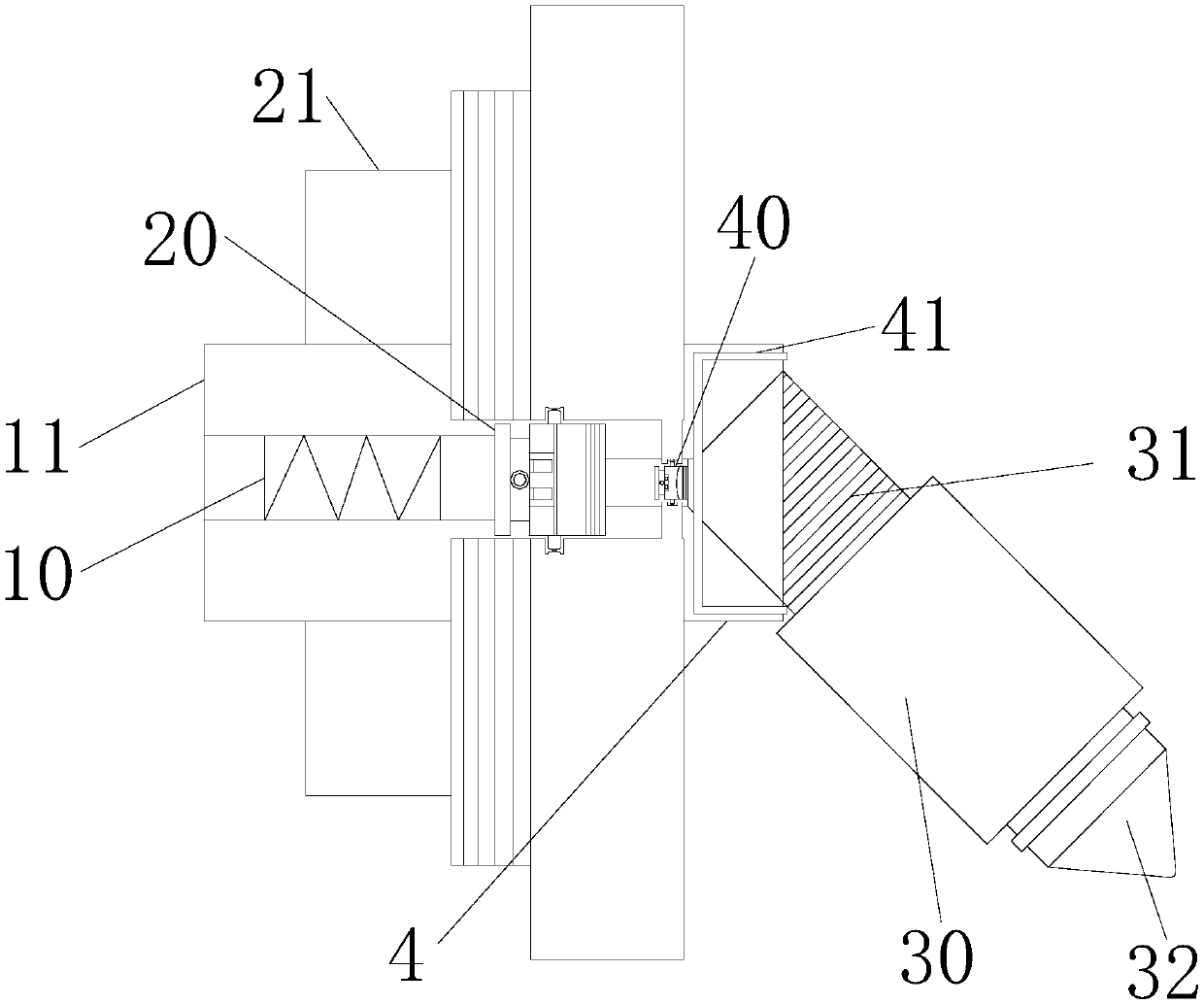

Cleaning device for nozzle sanitary ware

ActiveCN107583799BImplement activity regulationRealize up and down activitiesSpraying apparatusConvex structureDevice form

The invention discloses a cleaning device for nozzle sanitary fittings. The cleaning device structurally comprises a connector, a water outlet device, a water spray head and a rotating device. The connector and the water outlet device are mechanically connection and form a convex structure, and the water outlet device is movably connected with the water spray head through the rotating device. Theconnector, the water outlet device, the water spray head and the rotating device form an integrated structure. The water outlet device is composed of an opening and closing mechanism and a rotating bolt ring. The opening and closing mechanism is arranged in the middle of the rotating bolt ring and is in contact with the rotating bolt ring. On the premise of water outflow, the water spray head canmovably rotate in multiple directions for cleaning.

Owner:XUZHOU SHUNFENG VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com