System and method for comprehensive utilization of waste heat from sodium formate synthesis tail gas

A technology for synthesizing tail gas and sodium formate, which is applied in heating devices, generation of other non-combustion heat, preparation/separation of ammonia, etc., can solve problems such as energy waste, and achieve the effects of saving desalinated water, reducing steam consumption, and greatly promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

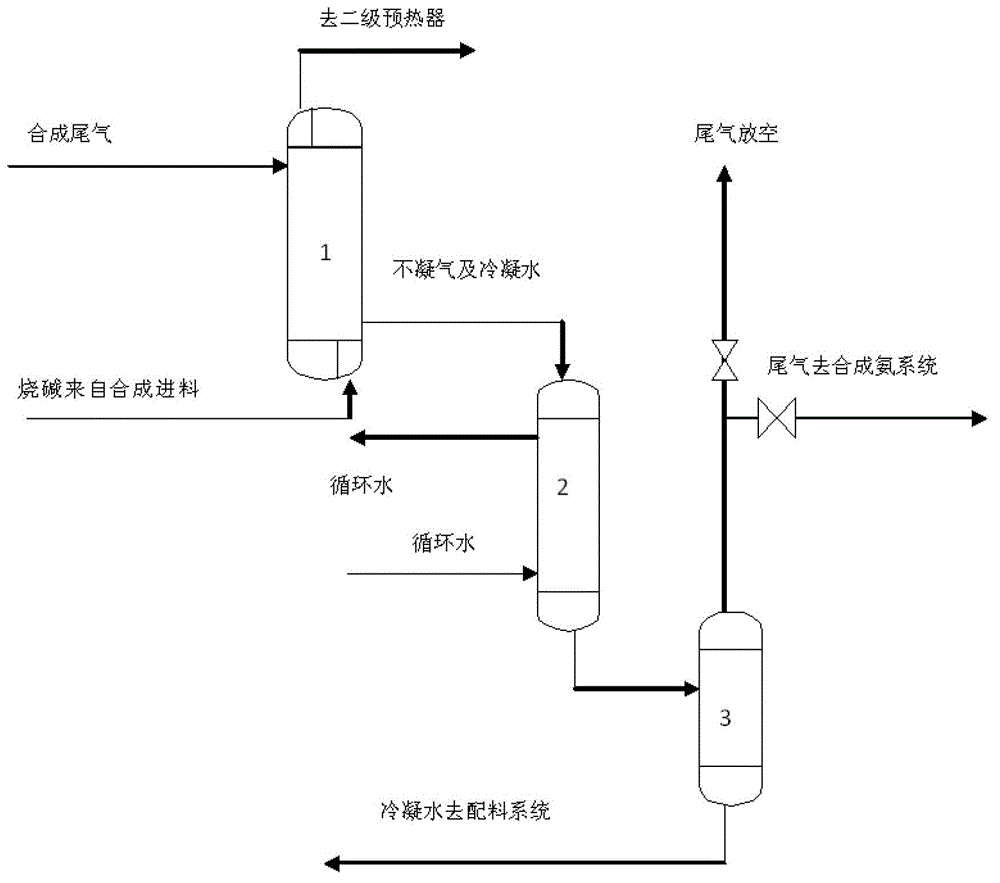

[0015] Such as figure 1 As shown, the tail gas from the synthesis section in the production of sodium formate passes through the primary preheater 1 for heat exchange and cooling, and the tail gas after heat exchange and cooling, that is, non-condensable gas and condensed water, passes through the tail gas cooler 2 and then enters the tail gas separator 3 for separation The tail gas after moisture is vented or enters the synthetic ammonia system, and the condensed water recovered during the whole process enters the batching system of the synthesis section.

[0016] The heat exchange area of the primary preheater is 260m 2 The shell side is 316L, the tube side is 0Cr25Ni20; the exhaust gas goes through the shell side, the caustic soda goes through the tube side, and a three-tube heat exchanger is used; the temperature of the tail gas entering the primary preheater is 160~180°C, and the pressure is 0.8~ 1.2Mpa, the nominal diameter of the delivery pipeline is DN100; the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com